Monodisperse core-shell structure polymer nano particle as well as preparation and application thereof

A core-shell structure, nanoparticle technology, applied in material separation, material analysis, other chemical processes, etc., can solve the problems of unfavorable large-scale protein sample pretreatment, low efficiency of post-modification grafting strategy, cumbersome steps, etc. The effect of hydrophilicity, clean and smooth particles, high glycoprotein adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

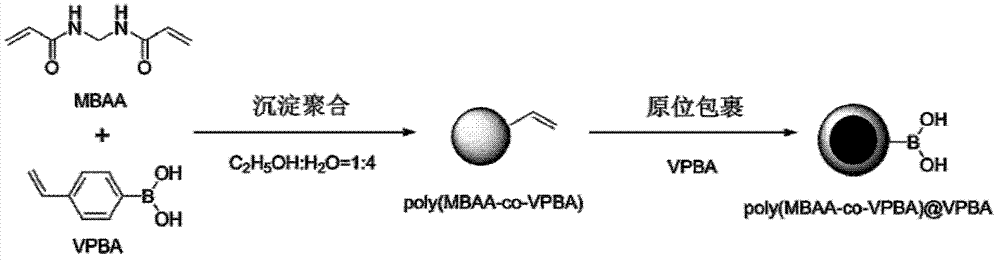

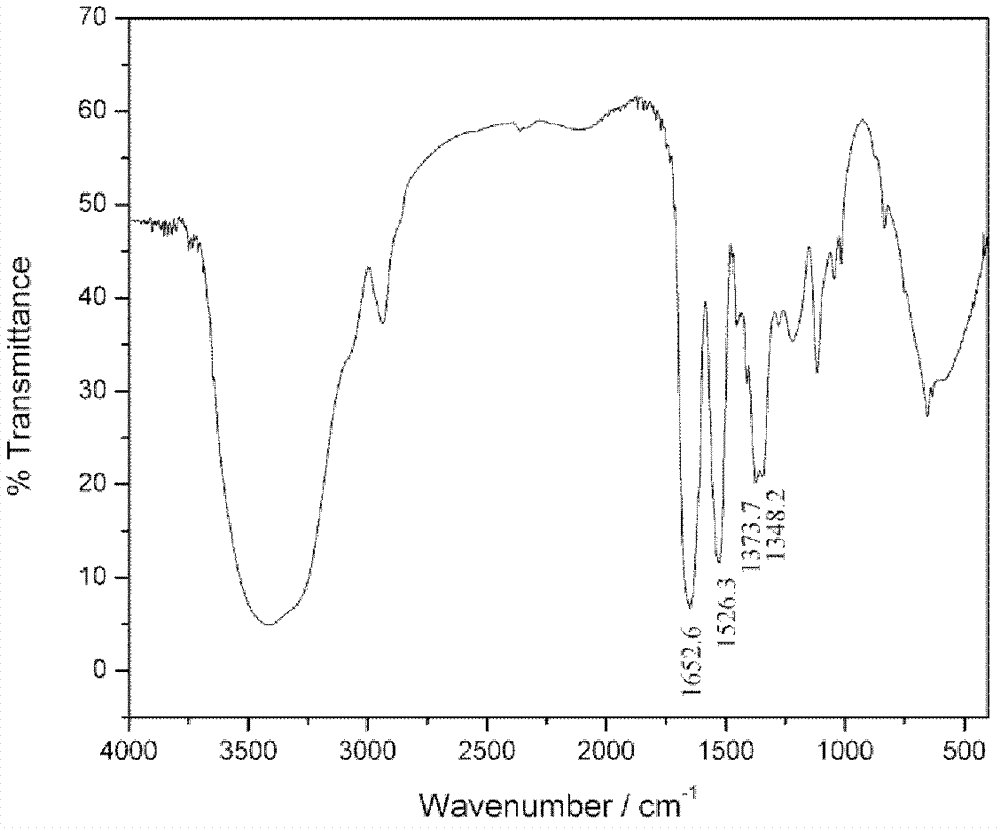

[0028] 1. Preparation of monodisperse core-shell polymer nanoparticles

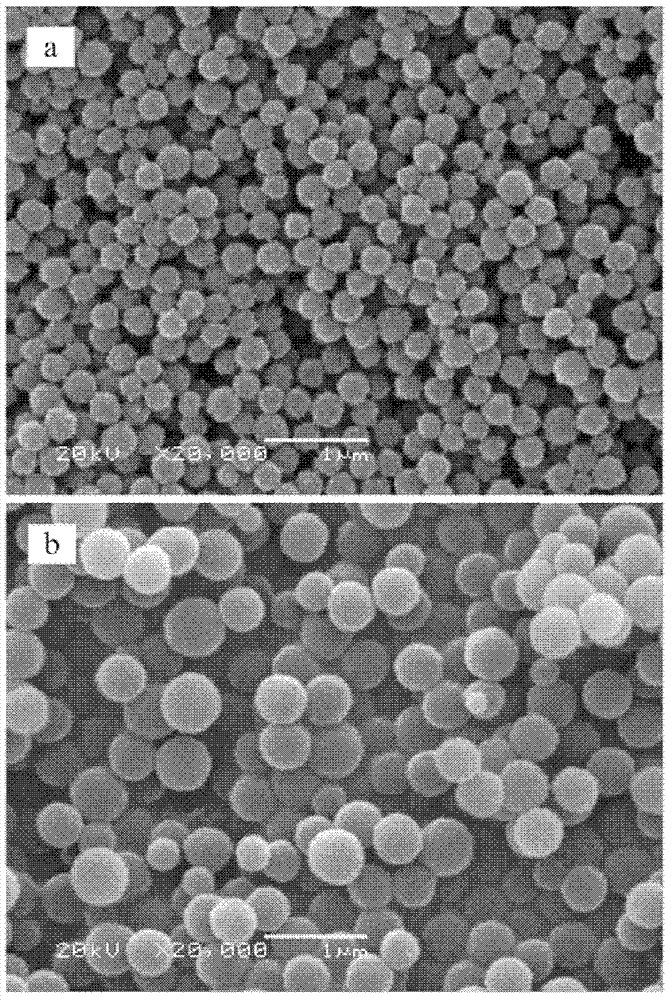

[0029] Such as figure 1 As indicated, weigh 33.8mg of 4-vinylphenylboronic acid (VPBA) and add it into a 50mL round bottom flask containing 2mL of ethanol, and sonicate for 5min. After the monomer was dissolved, 8 mL of water, 212.2 mg of N,N'-methylenebisacrylamide (MBAA) and 5 mg of azobisisobutyronitrile (AIBN) were added to the flask, and the mixture was sonicated until the mixture was completely dissolved. The flask was placed in an oil bath, and the temperature was raised from room temperature to 70° C., and kept stirring and heating at this temperature for 18 hours. After the reaction is finished, the solution is milky, thereby preparing the polymer core.

[0030] Weigh 33.8mg VPBA and 5mg AIBN respectively, and dissolve them in 2mL ethanol by ultrasonic. The solution was added to the polymerization system after the above reaction, stirred and heated at 70° C. for 6 hours, and the solution was s...

Embodiment 2

[0035] 1. Protein mixed solution preparation

[0036] Glycoprotein (horseradish peroxidase, HRP) and non-glycoprotein (bovine serum albumin, BSA) were mixed at a mass ratio of 1:1 and dissolved in 50 mM ammonium bicarbonate buffer solution (pH 9.0) to prepare A protein mixture solution with a concentration of 100 ng / μL was obtained.

[0037] 2. Selective enrichment of glycoproteins

[0038]Weigh 1 mg of core-shell polymer nanoparticles prepared in Example 1, disperse in 200 μL of the above protein mixture solution, shake gently at room temperature for 2 hours, centrifuge and discard the supernatant after the reaction is completed. The material was washed several times with 50 mM ammonium bicarbonate buffer solution (pH 9.0), and the supernatant was discarded by centrifugation. Add 20 μL of 50% acetonitrile solution containing trifluoroacetic acid (1% volume fraction of trifluoroacetic acid) to the separated material, and shake gently at room temperature for 1 hour. The supe...

Embodiment 3

[0043] In order to investigate the selectivity and non-specific adsorption of polymer nanoparticles in the process of glycoprotein enrichment, further interference experiments were carried out. HRP and BSA were mixed at a mass ratio of 1:500 and dissolved in 50 mM ammonium bicarbonate buffer solution (pH 9.0) to prepare a protein mixed solution with a concentration of 25.05 μg / μL. Weigh 1 mg of core-shell polymer nanoparticles, and carry out glycoprotein enrichment and subsequent MALDI-TOF MS identification under the conditions of Example 2.

[0044] Such as Figure 5 As shown, due to the extremely low concentration of HRP in the stock solution, the mass spectrometry response signal was inhibited by BSA and could not be detected (a curve); after enrichment by core-shell polymer nanoparticles, the HRP signal intensity increased significantly (c curve); and excluded The effect of interfering proteins was eliminated, so that BSA was only detected in the supernatant (b curve). I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com