Method for preparing flavonoid glycoside and stibene glucoside type compound by separating from fenugreek

A technology of stilbene glycosides and flavonoid glycosides, which is applied in the field of separation and preparation of natural medicines, can solve the problems of large consumption of organic reagents, difficulty in efficient separation, long required period, etc., and achieves shortened separation time, simple process, heavy weight, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] 1) Preparation of the sample to be separated:

[0068] Take 10 g of mature and dry seeds of wild or cultivated fenugreek plants, cut or crush them, pass through a 40-mesh sieve, extract with 100 mL of ethanol aqueous solution with a concentration of 95% by mass, and conduct heating and reflux extraction for 3 times at an extraction temperature of 90°C , each 2h, combined and concentrated to obtain the fenugreek extract with a solid content of 48%;

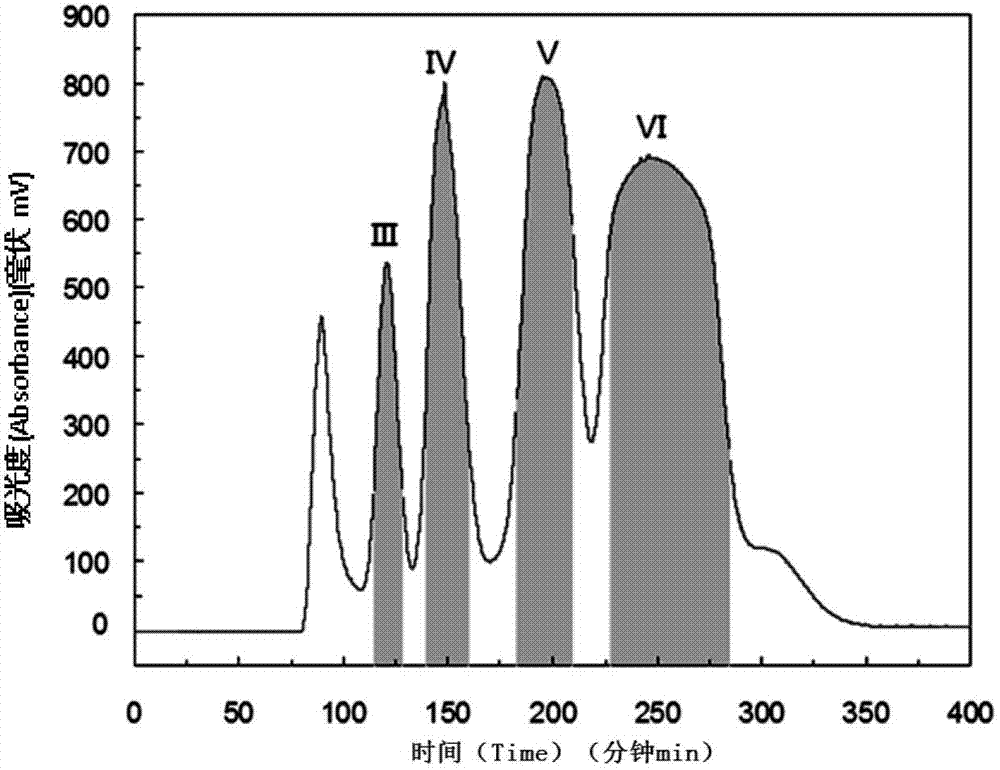

[0069] Get this fenugreek extract and dissolve it with deionized water earlier, after extracting 10 times with sherwood oil, collect the lower layer liquid and extract 10 times with ethyl acetate again, obtain ethyl acetate extract, 60 ℃, reduce under the condition of 0.07MPa Pressure evaporated to dryness to obtain 510 mg of sample A to be separated, figure 1 -A is the HPLC figure of sample A to be separated;

[0070] 2) Preparation by high-speed countercurrent chromatography:

[0071] High-speed countercurrent chromatog...

Embodiment 2

[0096] 1) Preparation of samples to be separated

[0097] Take 10g of mature and dry seeds of wild or cultivated fenugreek plants, cut or crush them, pass through a 60-mesh sieve, and extract them ultrasonically in 80mL of 60% ethanol aqueous solution at an extraction temperature of 80°C and an ultrasonic power of 120W. 2 times, each 1h, combined and concentrated to obtain the fenugreek extract with a solid content of 45%;

[0098] Take the fenugreek extract and dissolve it with deionized water first, then extract it with petroleum ether for 5 times, collect the lower layer liquid and extract it with ethyl acetate for 5 times to obtain the ethyl acetate extract, and reduce it under the conditions of 50°C and 0.08Pa Evaporate under pressure to obtain 430 mg of sample A to be separated;

[0099] 2) Preparation by high-speed countercurrent chromatography:

[0100] High-speed countercurrent chromatography (Shanghai Tongtian Biochemical Co., Ltd.) was used to separate and prepare...

Embodiment 3

[0109] 1) Preparation of samples to be separated

[0110] Take 10 g of mature and dry seeds of wild or cultivated fenugreek plants, cut or crush them, pass through a 40-mesh sieve, and microwave-assisted in 50 mL of 75% ethanol aqueous solution at an extraction temperature of 70 °C and a microwave power of 500 W. Extract 1 time, 90s each time, combine and concentrate to obtain the fenugreek extract with a solid content of 51%;

[0111] Take the fenugreek extract and dissolve it with deionized water first, then extract it twice with petroleum ether, collect the lower layer liquid and then extract it twice with ethyl acetate to obtain the ethyl acetate extract. Evaporate to dryness under reduced pressure to obtain 420 mg of sample A to be separated;

[0112]2) Preparation by high-speed countercurrent chromatography:

[0113] High-speed countercurrent chromatography (Shanghai Tongtian Biochemical Co., Ltd.) was used to separate and prepare deoxyrhein, emodin, orientin, vitexin,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com