Electrochemical-biological membrane synergistic reactor and application thereof in nitrogen-containing organic wastewater

A synergistic, reactor technology, applied in chemical instruments and methods, biological water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc. There are few problems in capacity research, so as to achieve the effect of increasing joint processing capacity, saving energy and improving denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

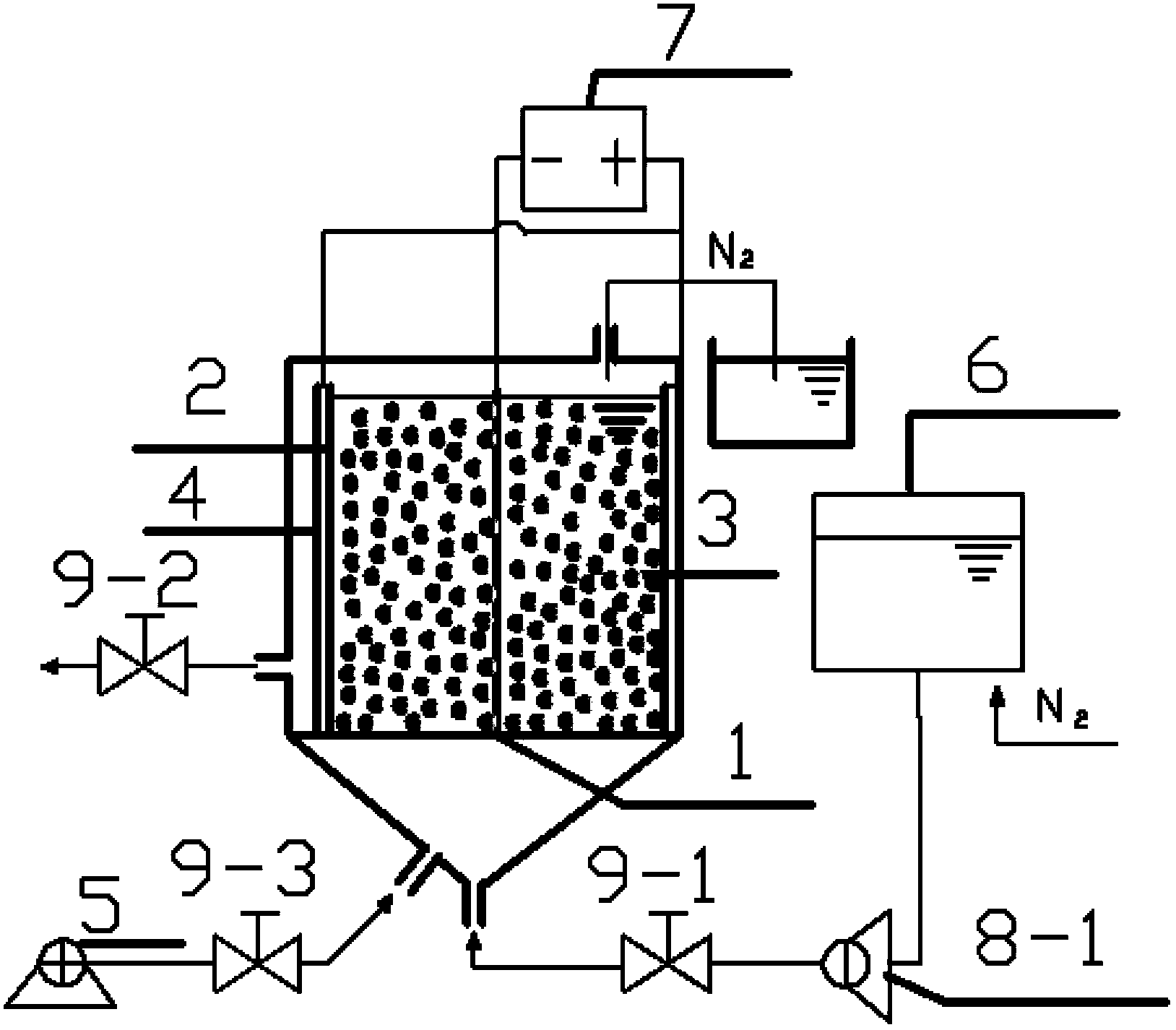

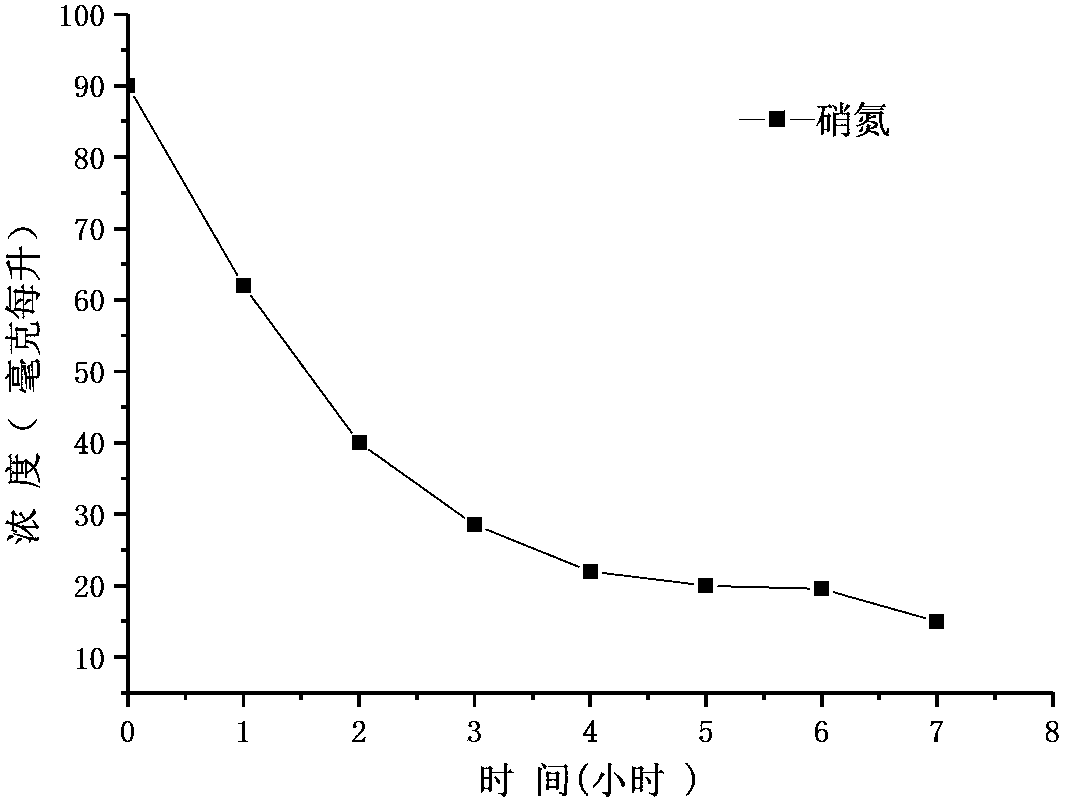

[0036] The graphite carbon plate wound with activated carbon fiber is used as the cathode, the titanium, iridium and ruthenium steady-state electrode is the anode, the electrode spacing is 3cm, and the activated carbon particles loaded with denitrifying paracoccus are used as the filler, and then the ratio is 1:6 The magnet particles are mixed evenly with it, and then the simulated wastewater containing nitrate nitrogen concentration of 90mg / L and pH of 7.5 enters the reactor from the water inlet through the peristaltic pump 10-1, and the influent flow rate is adjusted so that the hydraulic retention time is 7h , the applied current density is 30mA / cm 2 , The intermittent reaction time is 20 minutes, and the intermittent time and reaction time are 1:1. According to this cycle, samples are taken every 1h to determine the concentration of nitrate nitrogen in the effluent. The processing effect is attached figure 2 As shown, after 7 hours, the concentration of nitrate nitrogen ...

Embodiment 2

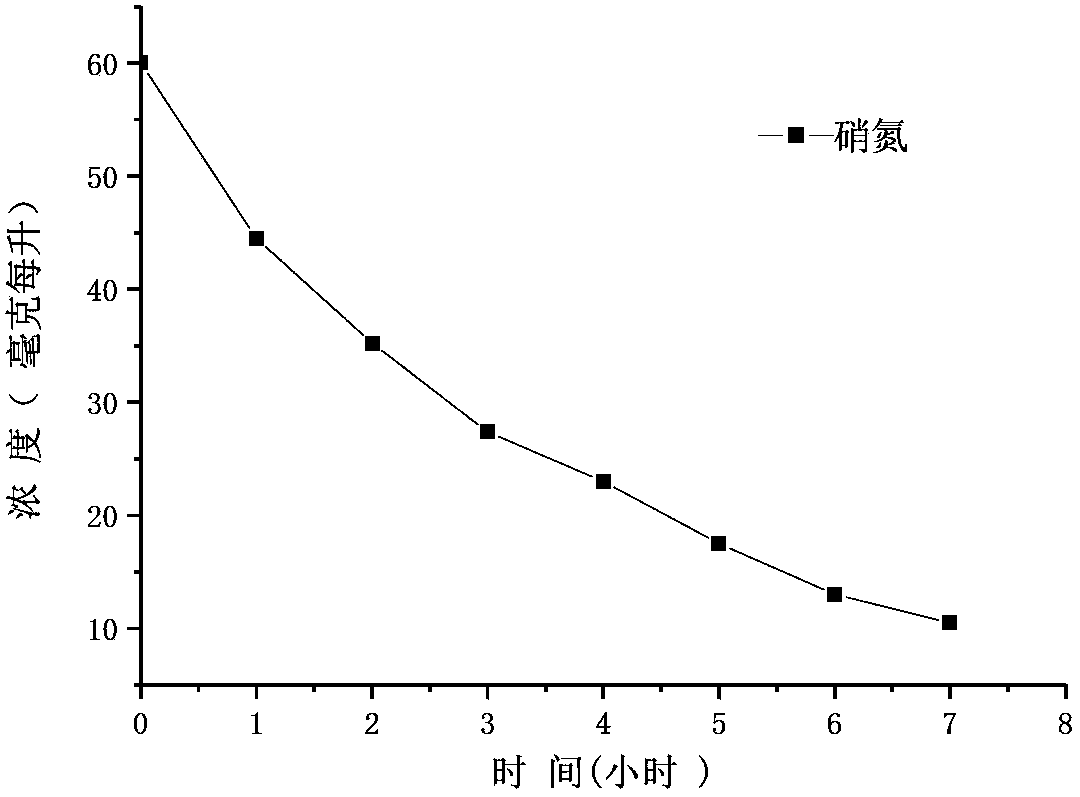

[0038] The graphite carbon plate wound with activated carbon fiber is used as the cathode, the titanium, iridium and ruthenium steady-state electrode is the anode, the electrode distance is 3 cm, and the activated carbon particles loaded with denitrifying paracoccus are used as the filler, and the ratio is 1:5. The magnet particles are evenly mixed with it, and the simulated wastewater containing nitrate nitrogen concentration of 60mg / L and pH of 7.5 enters the reactor through the water inlet through the peristaltic pump 10-1, and the influent flow rate is adjusted so that the hydraulic retention time is 7h. The current density is 30mA / cm 2 , The reaction interval time is 20 minutes, the interval time and the reaction time are 1:1, according to this cycle treatment, and the concentration of nitrate nitrogen in the effluent is measured by sampling every 1h. The processing effect is attached image 3 As shown, after 7 hours, the concentration of nitrate nitrogen in the effluent...

Embodiment 3

[0040] The graphite carbon plate wound with activated carbon fiber is used as the cathode, the titanium, iridium and ruthenium steady-state electrode is the anode, the distance between the electrodes is 3 cm, and the activated carbon particles loaded with denitrifying paracoccus are used as the filler, and the magnet with a ratio of 1:4 The particles are mixed evenly with it, and the simulated wastewater containing ammonia nitrogen concentration of 30mg / L and pH of 7.5 enters the reactor from the water inlet through the peristaltic pump 10-1, and the water flow rate is adjusted so that the hydraulic retention time is 7h, and the current density is applied 30mA / cm 2 , The intermittent reaction time is 20 minutes, and the intermittent time and reaction time are 1:1. According to this cycle, samples are taken every 1h to determine the concentration of nitrate nitrogen in the effluent. The processing effect is attached Figure 4 As shown, after 7 hours, the concentration of nitra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com