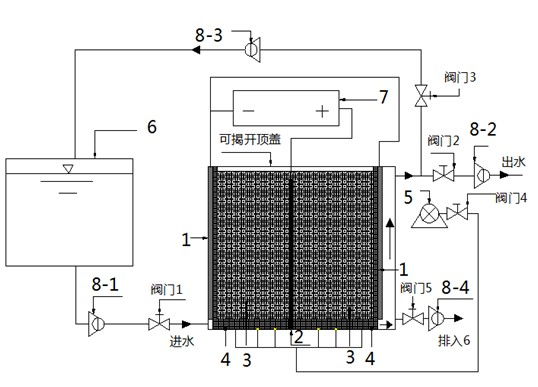

Compound three-dimensional electrode reactor and application thereof in treatment of nitrogenous organic wastewater

A three-dimensional electrode and reactor technology, applied in the field of environmental engineering, can solve problems such as poor nitrate nitrogen reduction ability and unsatisfactory COD removal effect, and achieve the effect of increasing combined treatment capacity, enhancing hydraulic retention time and mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

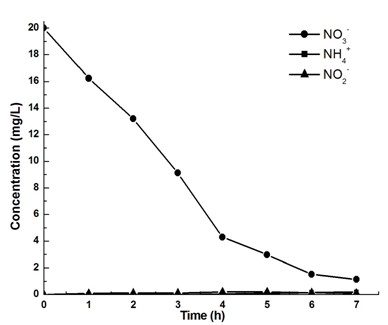

[0037] A copper-zinc alloy electrode is used as the cathode, a titanium-iridium-platinum electrode is used as the anode, and the distance between the electrodes is 4cm. Activated carbon is used as the filler. The ratio of conductive particles to insulating particles in the filler (obtained by coating polyvinyl alcohol (PVA) gel on the surface of reactivated carbon) The ratio is 1:1, the filling volume is 0.9L, and the wastewater containing nitrate nitrogen concentration of 20mg / L and NaCl concentration of 0.5g / L enters the reactor from the water inlet through the peristaltic pump 8-1, and the water inlet flow rate is adjusted so that the hydraulic The residence time is 1h, and the applied current density is 30mA / cm 2 , the effluent passes through the valve 3, the peristaltic pump 8-3 recirculates and then circulates, and measures the concentration of nitrate nitrogen, ammonia nitrogen and nitrite nitrogen in the effluent every 1h (in addition to most of the nitrate nitrogen bei...

Embodiment 2

[0039] A copper-zinc alloy electrode is used as the cathode, a titanium-iridium-platinum electrode is used as the anode, and the distance between the electrodes is 4cm. Activated carbon is used as the filler. The ratio of conductive particles to insulating particles in the filler (obtained by coating polyvinyl alcohol (PVA) gel on the surface of reactivated carbon) The ratio is 1:1, the filling volume is 0.9L, and the wastewater containing nitrate nitrogen concentration of 80mg / L and NaCl concentration of 0.5g / L enters the reactor from the water inlet through the peristaltic pump 8-1, and the water inlet flow is adjusted so that the hydraulic The residence time is 1h, and the applied current density is 30mA / cm 2 , the effluent passes through the valve 3, the peristaltic pump 8-3 recirculates and then circulates, and measures the concentration of nitrate nitrogen, ammonia nitrogen and nitrite nitrogen in the effluent every 1h (in addition to most of the nitrate nitrogen being co...

Embodiment 3

[0041] A copper-zinc alloy electrode is used as the cathode, a titanium-iridium-platinum electrode is used as the anode, and the distance between the electrodes is 4cm. Activated carbon is used as the filler. The ratio of conductive particles to insulating particles in the filler (obtained by coating polyvinyl alcohol (PVA) gel on the surface of reactivated carbon) The ratio is 1:1, the filling volume is 0.9L, and the wastewater containing ammonia nitrogen concentration of 10mg / L and NaCl concentration of 0.5g / L enters the reactor from the water inlet through the peristaltic pump 8-1, and the water flow rate is adjusted to make the hydraulic retention The time is 1h, and the applied current density is 30mA / cm 2 , the effluent passes through the valve 3, and the peristaltic pump 8-3 recirculates and then circulates, and measures the concentration of ammonia nitrogen in the effluent every 1 hour. Processing effect such as Figure 4 As shown, after 7 hours, the concentration of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com