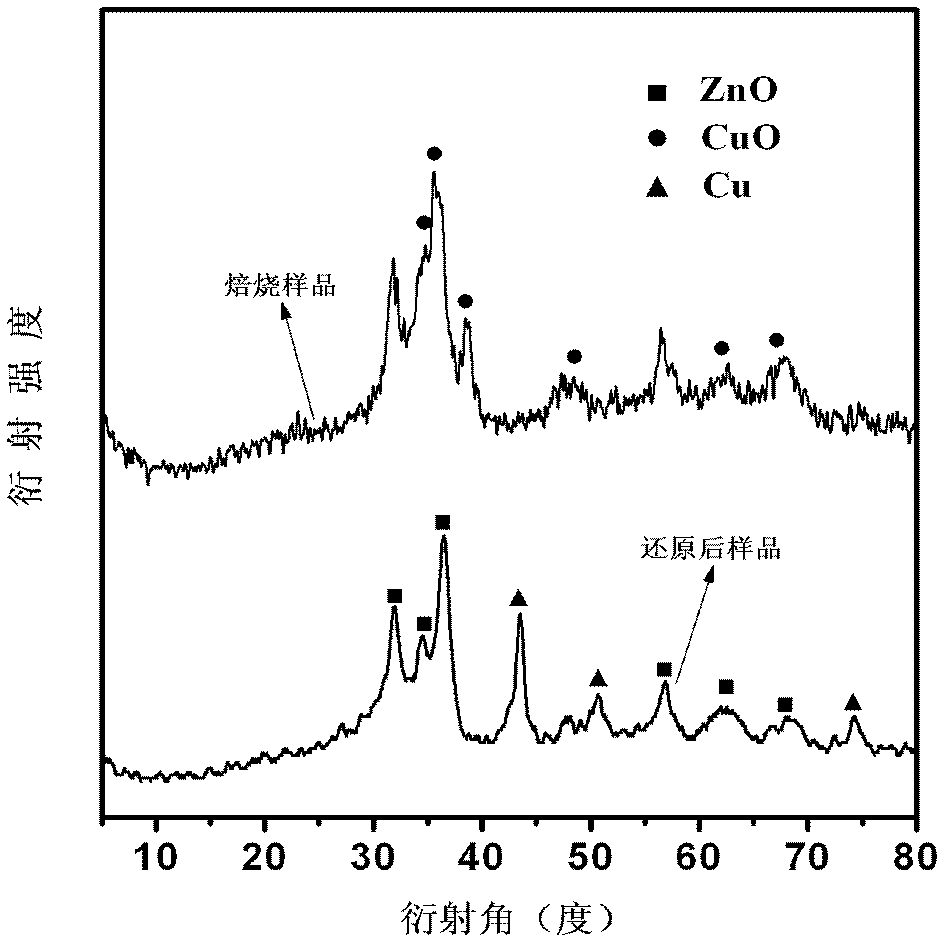

High-dispersion supported copper-based catalyst as well as preparation method and application thereof

A copper-based catalyst, supported technology, applied in the preparation of hydroxyl compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the adjustment of mixing uniformity and fineness, uneven composition and structure, affecting composite metal oxides performance and other problems, to achieve the effect of improving dispersibility, overcoming uneven mixing, and good catalytic hydrogenation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Accurately weigh Cu(NO 3 ) 2 ·6H 2 O, Zn(NO 3 ) 2 ·6H 2 O and Zr(NO 3 ) 4 9H 2 O, prepare mixed salt solution with deionized water, Cu in the solution 2+ The molar concentration of Zn is 0.06mol / L, Zn 2+ The molar concentration is 0.06mol / L, Zr 4+ The molar concentration is 0.06mol / L. Dissolve sodium hydroxide, sodium carbonate and cetyltrimethylammonium bromide in deionized water to prepare a mixed alkaline solution, wherein the molar concentration of sodium hydroxide is 0.25mol / L, and the molar concentration of sodium salt is 0.12mol / L , the concentration of cetyltrimethylammonium bromide is 0.09mol / L. Pour 100ml of the mixed salt solution and 100ml of the mixed alkaline solution into the fully back-mixed liquid membrane reactor at the same time, stir at a speed of 6000 rpm for 2 minutes, and then add it together with 100ml of water into a 500ml single-necked flask for crystallization at 60°C for 12 hours. Then centrifuge and wash 5 times with hot deionize...

Embodiment 2

[0025] Accurately weigh Cu(NO 3 ) 2 ·6H 2 O, Mg(NO 3 ) 2 ·6H 2 O and Zr(NO 3 ) 4 9H 2 O, prepare mixed salt solution with deionized water, Cu in the solution 2+ The molar concentration is 0.06mol / L, Mg 2+ The molar concentration is 0.06mol / L, Zr 4+ The molar concentration is 0.03mol / L. Dissolve sodium hydroxide, sodium carbonate and polyvinylpyrrolidone in deionized water to prepare a mixed alkaline solution, wherein the molar concentration of sodium hydroxide is 0.30mol / L, the molar concentration of sodium salt is 0.06mol / L, and the concentration of polyvinylpyrrolidone is 0.06 mol / L. Pour 100ml of the mixed salt solution and 100ml of the mixed alkaline solution into the fully back-mixed liquid membrane reactor at the same time, stir at a speed of 3000 rpm for 2 minutes, and then add it together with 100ml of water into a 500ml one-mouth bottle for crystallization at 60°C for 12 hours. Then centrifuge and wash 5 times with hot deionized water until the pH reaches ...

Embodiment 3

[0028] Accurately weigh Cu(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O and Zr(NO 3 ) 4 9H 2 O, prepare mixed salt solution with deionized water, Cu in the solution 2+ The molar concentration is 0.06mol / L, Co 2+ The molar concentration is 0.06mol / L, Zr 4+ The molar concentration is 0.09mol / L. Dissolve sodium hydroxide, sodium carbonate and sodium lauryl sulfate in deionized water to prepare a mixed alkaline solution, wherein the molar concentration of sodium hydroxide is 0.48mol / L, the molar concentration of sodium salt is 0.18mol / L, and dodecane The sodium base sulfate concentration is 0.03mol / L. Pour 100ml of the mixed salt solution and 100ml of the mixed alkaline solution into the fully back-mixed liquid membrane reactor at the same time, stir at a speed of 5000 rpm for 2 minutes, and then add it together with 100ml of water into a 500ml single-necked flask for crystallization at 60°C for 12 hours. Then use hot deionized water to centrifuge and wash 5 times until the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com