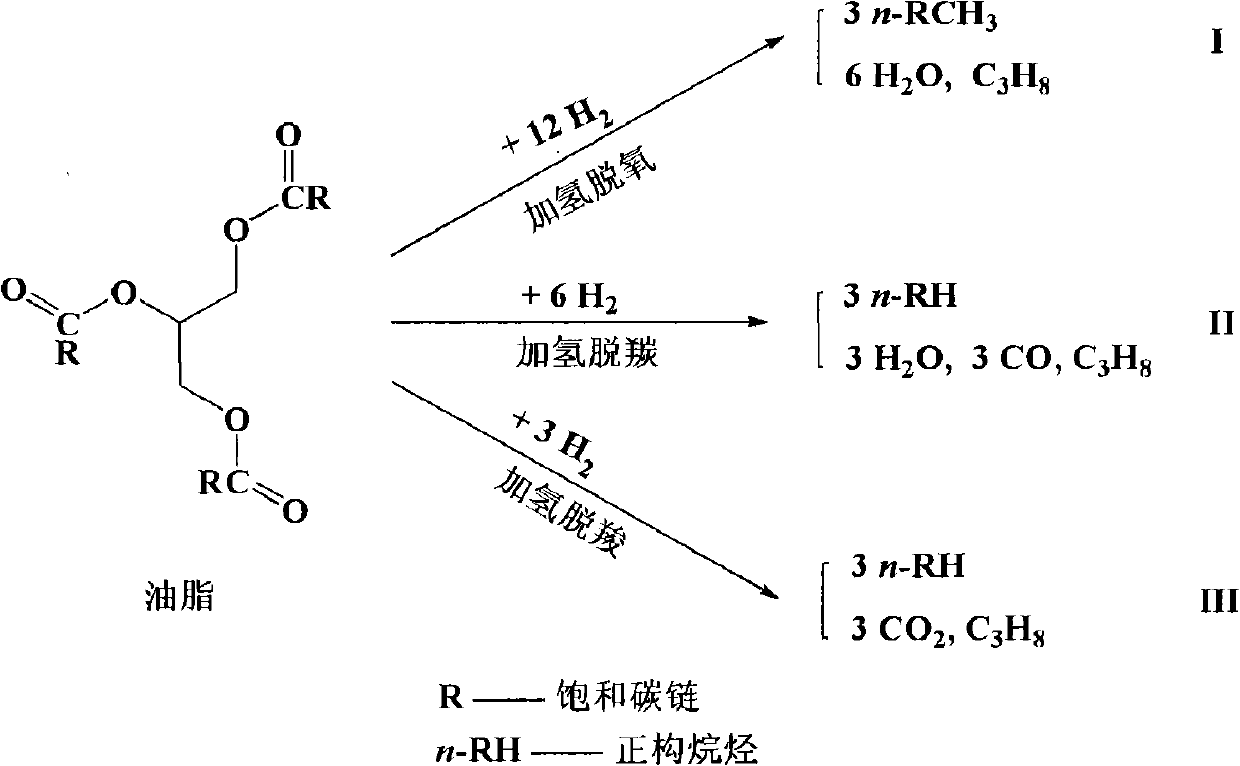

Conversion process of grease

A technology of oil and catalyst, applied in the field of organic matter conversion process, can solve the problems of low freezing point, high hydrogen consumption and energy consumption, complex process, etc., and achieve the effect of low hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

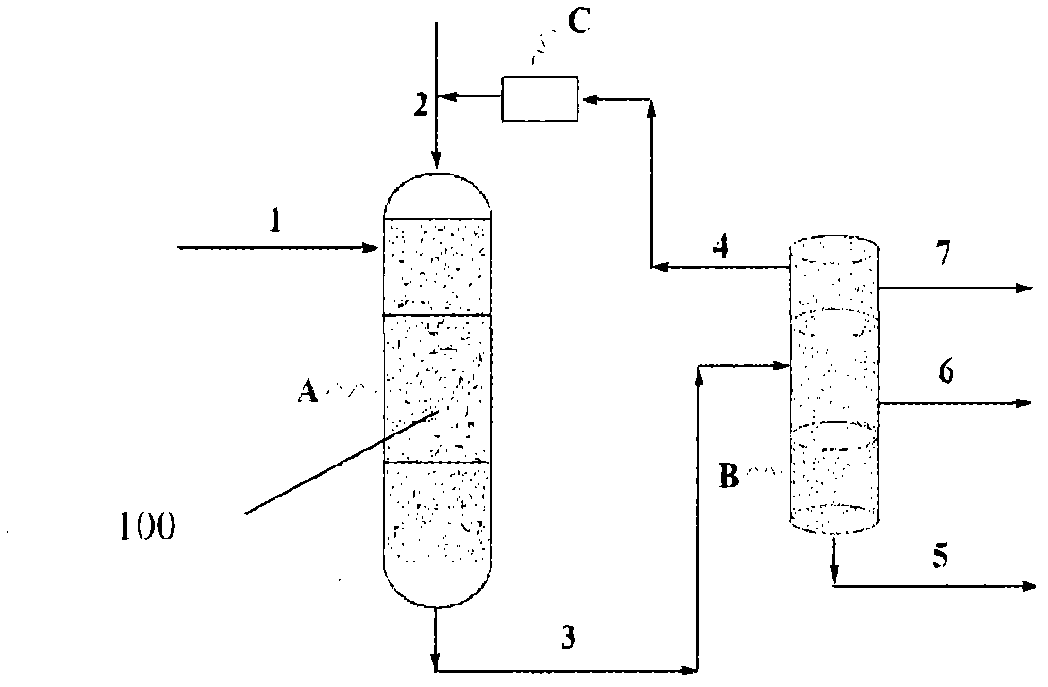

Method used

Image

Examples

Embodiment 1

[0117] Catalyst preparation

[0118] SAPO-11 and ZSM-22 molecular sieves were synthesized according to the methods in the literature Pure Appl. Chem. 58 (1986) 1351-1358 and Zeolites 5 (1985) 349-351. γ-Al used 2 o 3 Produced for Shandong Aluminum Co., Ltd. The synthesized molecular sieve and 30wt.% γ-Al 2 o 3 Mixing, extruding, molding, calcining and other steps to prepare the catalyst carrier. The catalysts in all the following examples were prepared by incipient wetness impregnation.

[0119] The incipient wetness impregnation method is a well-known method for preparing supported catalysts. Its general steps are: impregnating a salt solution containing catalytically active metal element M1 with a total volume equal to the total pore volume of the support into the support; The total volume of the absorbed impregnating liquid is equal to the total pore volume of the carrier, so that all the impregnating liquid enters the pores of the carrier, and no obvious impregnating...

Embodiment 2

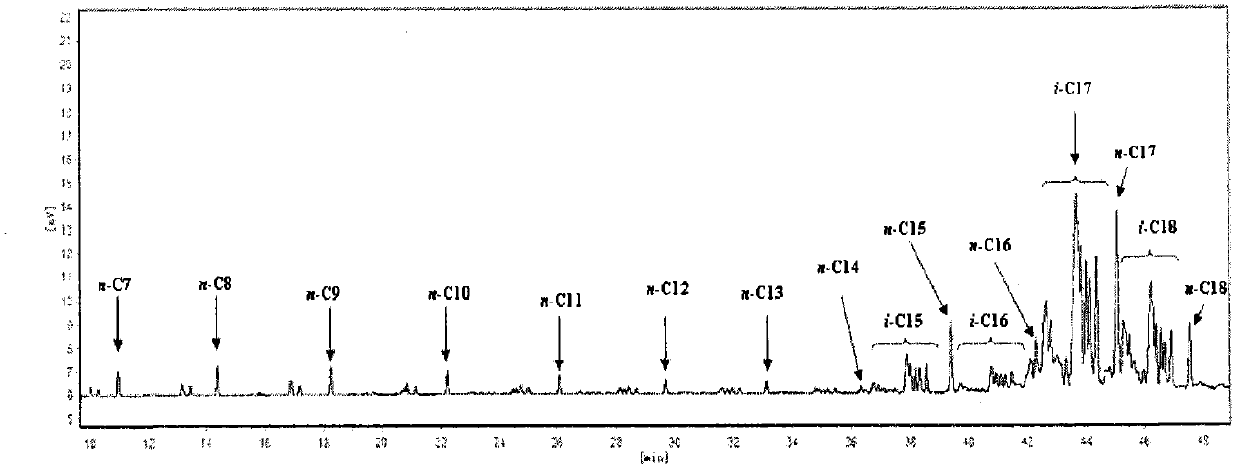

[0130] One-step production of second-generation biodiesel and / or biojet fuel from soybean oil using Pt / SAPO-11 catalyst

[0131] Weigh 7.5g of Pt / SAPO-11 catalyst (10mL, particle size 10-20 mesh) with a Pt loading of 1wt.%, and put it in a stainless steel fixed-bed reactor with an inner diameter of 10mm and a tube length of 0.6m. Both ends of the reactor are filled with 20-40 mesh quartz sand. Hydrogen was introduced into the reactor, and soybean oil (produced by COFCO Corporation, grade 3, in line with GB1535-2003 national standard) was used as raw material for sample injection. The reaction conditions are: 357°C, 4.0MPa, LHSV for 1h -1 , the hydrogen-oil ratio is 1765NL / L. After 3 hours of reaction, samples were taken, the gas phase products were analyzed by GC-TCD, and the liquid phase products were analyzed by GC-FID and GC-MS.

[0132] The reaction results are: the conversion rate of raw materials is 100%, the sum of decarboxylation and decarbonylation rates is 70.6%, ...

Embodiment 3

[0134] One-step production of second-generation biodiesel and / or biojet fuel from soybean oil using Pt / SAPO-11 catalyst

[0135] Weigh 8.1g of Pt / SAPO-11 catalyst (10mL, particle size 10-20 mesh) with a Pt loading of 1wt.%, and put it in a stainless steel fixed-bed reactor with an inner diameter of 10mm and a tube length of 0.6m. Both ends of the reactor are filled with 20-40 mesh quartz sand. Hydrogen was introduced into the reactor, and soybean oil (produced by COFCO Corporation, grade 3, in line with GB1535-2003 national standard) was used as raw material for sample injection. The reaction conditions are: 339°C, 2.0MPa, LHSV 0.6h -1 , the hydrogen-oil ratio is 1765NL / L. After 3 hours of reaction, samples were taken, the gas phase products were analyzed by GC-TCD, and the liquid phase products were analyzed by GC-FID and GC-MS.

[0136] The reaction results are: the conversion rate of raw materials is 99.2%, the sum of decarboxylation and decarbonylation rates is 57.5%, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com