A method for rapidly degrading high-molecular-weight polyamino acids and its application

A high-molecular-weight, polyamino acid technology, applied in the fields of macromolecule and microwave chemistry, and bioengineering, can solve the problems of high molecular weight polyamino acids, achieve high application value, high thermal efficiency, and improve reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

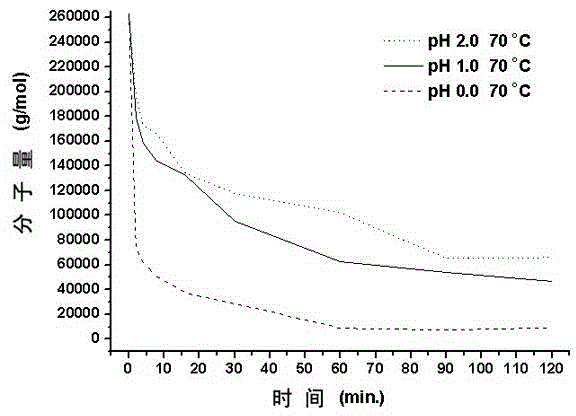

[0043] Weigh 1g of γ-polyglutamic acid and dissolve it in 50mL of pure water, and adjust the pH value to 0.0 with hydrochloric acid respectively. A three-necked round-bottomed flask is used as a container, one of which is the feeding port, one port is connected to the infrared temperature detection head, and the other port is connected to the reflux condensing device. The power of the microwave reactor was set at 500 W, the temperature of the microwave reaction was set at 70°C, and the reactions were performed for 2, 4, 8, 16, 30, 60, 90, and 120 minutes, respectively. The resulting degradation product was dialyzed in pure water for 48 hours with a dialysis bag with a molecular weight cut-off of 7000 Da, and then freeze-dried to obtain a powder product.

Embodiment 2

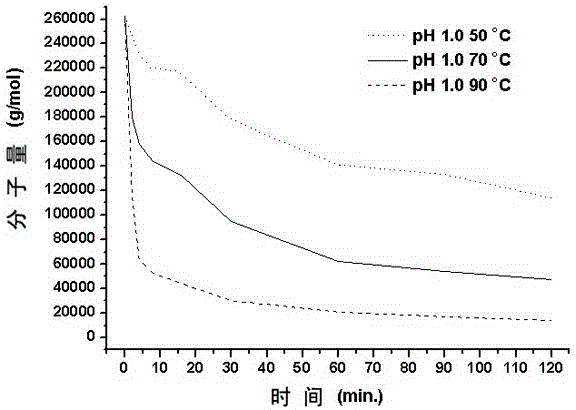

[0045] Weigh 1g of γ-polyglutamic acid and dissolve it in 50mL of pure water, and adjust the pH to 1.0 with hydrochloric acid. A three-necked round-bottomed flask is used as a container, one of which is the feeding port, one port is connected to the infrared temperature detection head, and the other port is connected to the reflux condensing device. The power of the microwave reactor was set at 500 W, the temperature of the microwave reaction was set at 70°C, and the reactions were performed for 2, 4, 8, 16, 30, 60, 90, and 120 minutes, respectively. The resulting degradation product was dialyzed in pure water for 48 hours with a dialysis bag with a molecular weight cut-off of 7000 Da, and then freeze-dried to obtain a powder product.

Embodiment 3

[0047] Weigh 1g of γ-polyglutamic acid and dissolve it in 50mL of pure water, and adjust the pH value to 2.0 with hydrochloric acid respectively. A three-necked round-bottomed flask is used as a container, one of which is the feeding port, one port is connected to the infrared temperature detection head, and the other port is connected to the reflux condensing device. The power of the microwave reactor was set at 500 W, the temperature of the microwave reaction was set at 70°C, and the reactions were performed for 2, 4, 8, 16, 30, 60, 90, and 120 minutes, respectively. The resulting degradation product was dialyzed in pure water for 48 hours with a dialysis bag with a molecular weight cut-off of 7000 Da, and then freeze-dried to obtain a powder product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com