A toothed spherical alumina carrier, a toothed spherical hydrotreating catalyst and a preparation method thereof

A spherical alumina and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, treatment of hydrocarbon oil, etc. The effect of reducing the amount, optimizing the pore size distribution, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

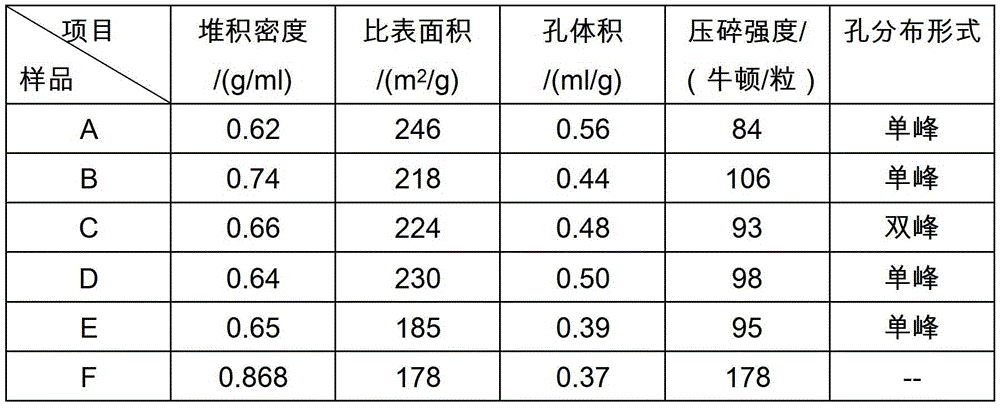

Examples

Embodiment 1

[0034] The preparation method of the toothed spherical alumina carrier described in this embodiment comprises the following steps:

[0035] (1) Weigh 100g of macroporous aluminum hydroxide with a pore diameter of 15-20nm produced by the carbonization method, 1.3g of the lubricant scallop powder, 3g of the dispersant ethyl cellulose, and 4g of the pore-enlarging agent sodium polyacrylate, and mix them by stirring After mixing the above-mentioned various components by machine for 20 minutes, add nitric acid solution 4g of peptizer mass concentration 60wt%, anionic surfactant dodecyl phosphate monoester 5g and deionized water 15g, then adopt kneader to mix 20 Minutes to make a soft block plastic body;

[0036] (2) Put the soft block-shaped plastic body prepared in step (1) into the chute of the extruder, extrude through the toothed spherical orifice plate, and then cut into pellets with a cutter, and keep it at room temperature for 40 minutes. , dried at 120°C for 3 hours, and c...

Embodiment 2

[0038] The preparation method of the toothed spherical alumina carrier described in this embodiment comprises the following steps:

[0039] (1) Weigh 100g of macroporous aluminum hydroxide with a pore diameter of 5-12nm produced by the carbonization method, 1.3g of a mixture of squash powder and stearic acid at a mass ratio of 1:1 as a lubricant, and ethyl cellulose as a dispersant 1.5 g of a mixture of cellulose and hydroxyethyl cellulose in a mass ratio of 1:1, and a pore-enlarging agent is a mixture of polyvinyl alcohol, sodium polyacrylate, starch derivatives and carbon black in a mass ratio of 1:1:1:1 1.5g, and use a stirring mixer to mix the above-mentioned various components for 40 minutes, add peptizers to be nitric acid solution (mass concentration is 60wt%), citric acid solution (mass concentration is 90wt%), acetic acid solution (mass concentration 30wt%) and tartaric acid solution (mass concentration 30wt%) with a mass ratio of 1:1:1:1 mixed acid solution consistin...

Embodiment 3

[0042] The preparation method of the toothed spherical alumina carrier described in this embodiment comprises the following steps:

[0043] (1) Weigh a total of 100g of the mixture of macroporous aluminum hydroxide produced by carbonization method and small-pore aluminum hydroxide produced by nitric acid method with a mass ratio of 1:1, 2g of lubricant kale powder, and dispersant ethyl cellulose 0.2g and 0.3g of pore-enlarging agent carboxymethyl starch, and after using a stirring mixer to mix the above-mentioned various components for 60 minutes, add 0.5g of acetic acid solution with a mass concentration of peptizer of 30wt%, and anionic surfactant butyloctyl Dithioester 0.2g and deionized water 14g, then adopt kneader to mix for 60 minutes, make soft lump plastic body;

[0044] (2) Put the soft block-shaped plastic body prepared in step (1) into the chute of the extruder, extrude through the toothed spherical orifice plate, and then cut into pellets with a cutter, and keep i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com