Method for preparing carbon-coated aluminum lithium battery negative pole material with core-shell structure and cavity

A core-shell structure and negative electrode material technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of easy cracking and pulverization of alloys, loss of reversible lithium storage function, irreversible capacity loss, etc., to achieve good conductivity, The effect of stable charge and discharge voltage platform and good electrode reaction reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

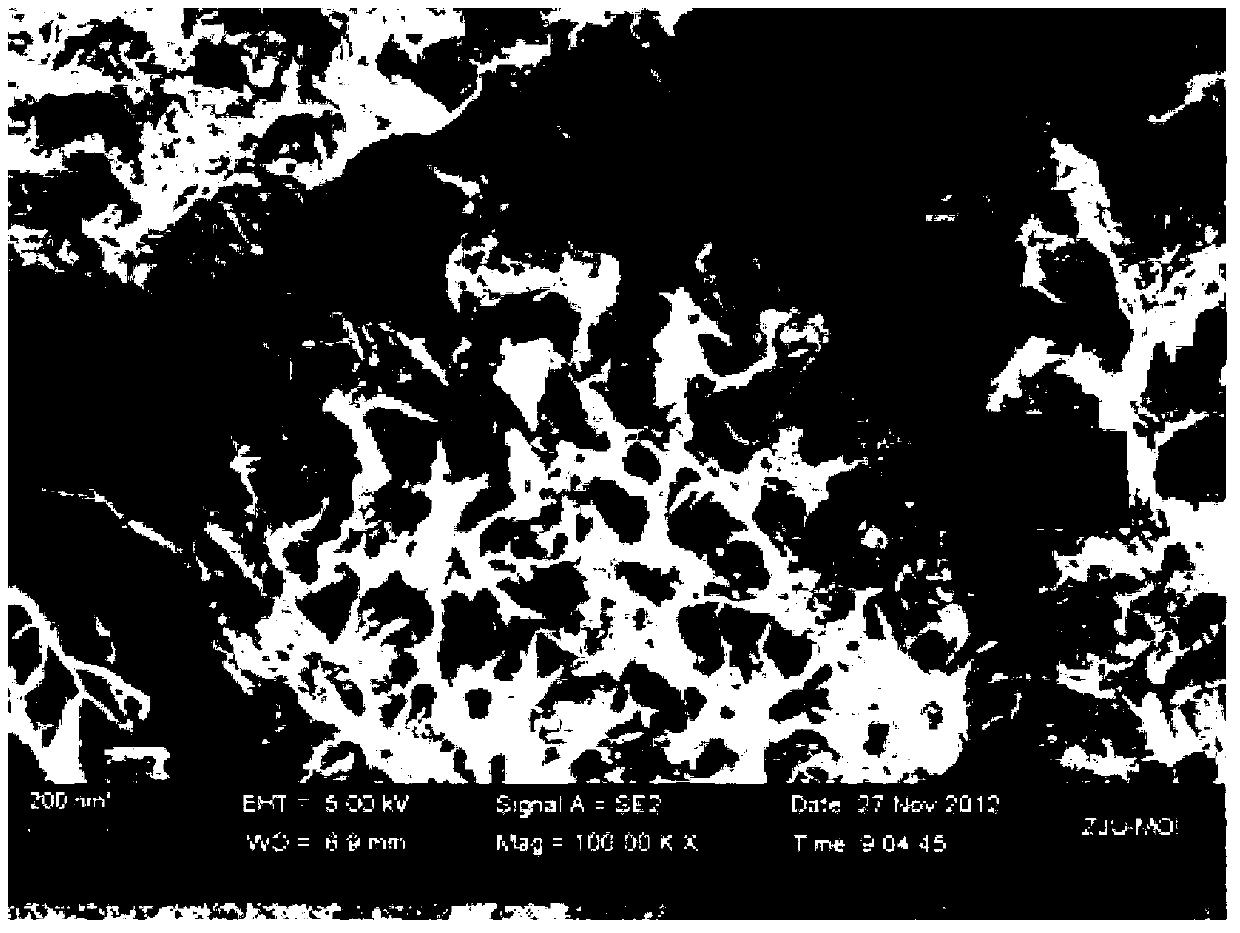

[0034] Example 1: Preparation of carbon-clad aluminum composite material precursor

[0035] Dissolve 2 g of glucose in 100 mL of deionized water, stir and dissolve, and then introduce it into a reactor with a total capacity of 150 mL. Then add 10 g of spherical aluminum powder with a purity of 99.99% and a particle size of 1 to 5 microns, and seal the reaction kettle after adding magnets. The reaction kettle was placed in an oil bath at 250° C., and the reaction kettle was taken out after 2 hours of magnetic stirring. After the reaction kettle is cooled to room temperature, open the reaction kettle and take out the filtered product. The product is in the form of brown or black solid powder, which is separated by centrifugation and washed with water and ethanol three times in the process of "centrifugation, washing and redispersion". The carbon-clad aluminum composite material precursor was obtained after vacuum drying at 40°C.

Embodiment 2

[0036] Example 2: Carbonization of precursors of carbon-clad aluminum composite materials

[0037] Dissolve 5 g of sucrose in 100 mL of deionized water, stir and dissolve, and then introduce it into a reactor with a total capacity of 150 mL. Then add 10 g of spherical aluminum powder with a purity of 99.99% and a particle size of 10 to 20 microns, and seal the reaction kettle after adding magnets. The reaction kettle was placed in an oil bath at 250° C., and the reaction kettle was taken out after 4 hours of magnetic stirring. After the reaction kettle is cooled to room temperature, open the reaction kettle and take out the filtered product. The product is in the form of brown or black solid powder, which is separated by centrifugation and washed with water and ethanol three times in the process of "centrifugation, washing and redispersion". The carbon-aluminum composite material precursor was obtained after vacuum drying at 40°C. The carbon-aluminum composite precursor was ...

Embodiment 3

[0038] Example 3: Preparation of Carbon-clad Aluminum Composite Material Post-treated with Hydrochloric Acid

[0039] 10 g of starch was dissolved in 100 mL of deionized water, stirred and dissolved, and introduced into a reactor with a total capacity of 150 mL. Then add 10 g of spherical aluminum powder with a purity of 99.99% and a particle size of 5 to 15 microns, and seal the reaction kettle after adding magnets. The reaction kettle was placed in an oil bath at 250° C., and the reaction kettle was taken out after 8 hours of magnetic stirring. After the reaction kettle is cooled to room temperature, open the reaction kettle and take out the filtered product. The product is in the form of brown or black solid powder, which is separated by centrifugation and washed with water and ethanol three times in the process of "centrifugation, washing and redispersion". The carbon-clad aluminum composite material precursor was obtained after vacuum drying at 40°C. The carbon-clad alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com