High-dielectric constant high-temperature resistant wire and preparation method for same

A technology of high temperature resistant wires and high dielectric constant, applied in the direction of cable/conductor manufacturing, conductors, circuits, etc., can solve the problems of wire insulation damage, moisture resistance, easy cracking, etc., to prevent moisture absorption and mechanical damage, storage Easy installation and excellent resistance to chemical solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

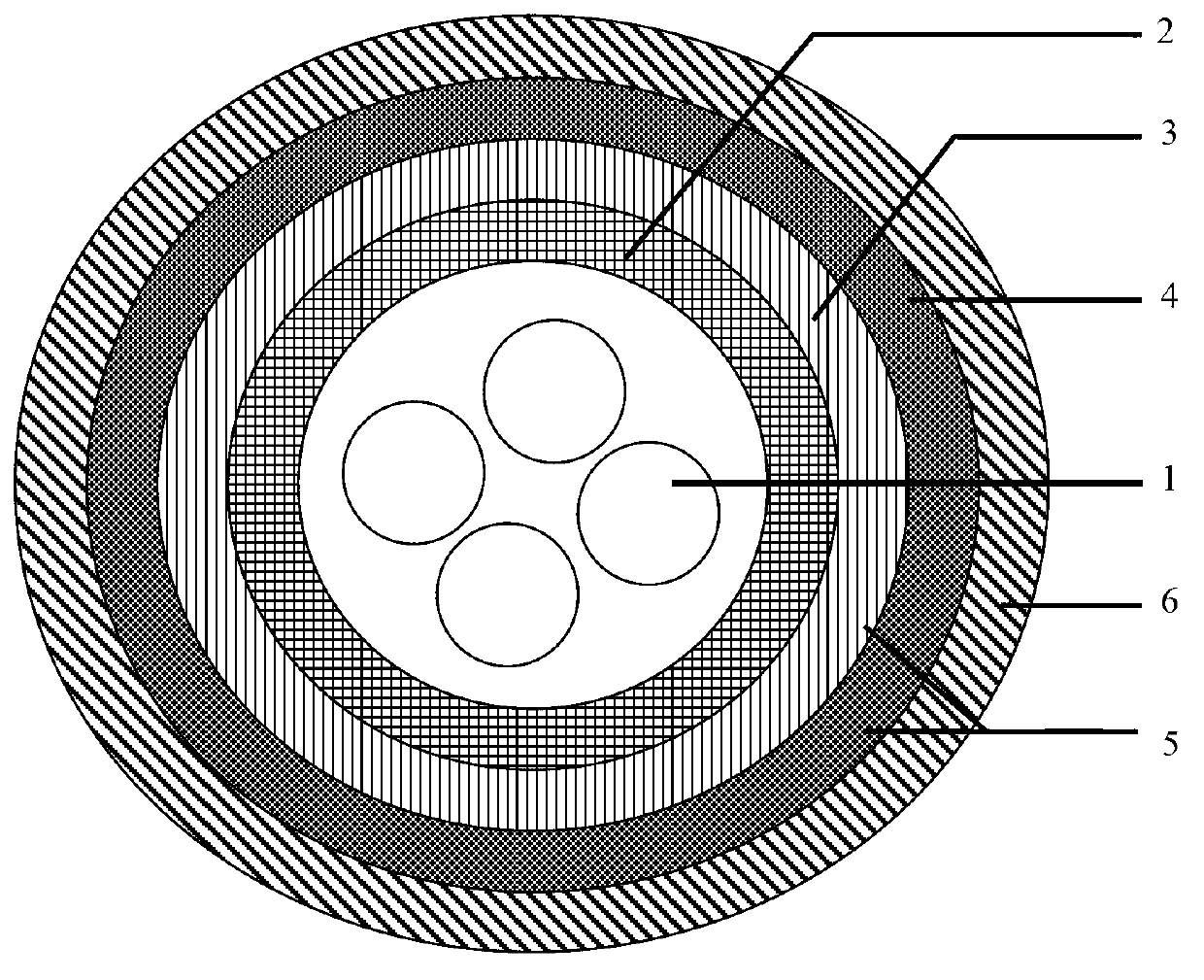

Image

Examples

Embodiment 1

[0053] 1) Multi-strand monofilament cores are twisted in the same direction to make conductive cores. The monofilament wire core used is a nickel-plated round copper wire, the volume percentage of the nickel layer is 12%, and the specification of the stranded conductive wire core is 127×0.300 (mm);

[0054] 2) Prepare a high temperature resistant insulating layer outside the stranded conductive wire core, the steps include mica tape wrapping, quartz fiber wrapping and quartz fiber weaving.

[0055] The mica tape used is made of mica paper and glass cloth bonded by high temperature resistant modified silicone resin paint. The mica tape used is 0.075×8mm and the coverage rate is 67%.

[0056] A high-speed wire wrapping machine is used to wrap the quartz fiber. The parameters of the quartz fiber package are: 4 strands, 210 strands per strand, and a covering rate of 5%;

[0057] Quartz fiber weaving is performed using a high-speed weaving machine. Quartz fiber weaving parameter...

Embodiment 2

[0078] 1) Multi-strand monofilament cores are twisted in the same direction to make conductive cores. The monofilament wire core used is a nickel-plated round copper wire, the volume percentage of the nickel layer is 9%, and the specification of the stranded conductive wire core is 127×0.300 (mm);

[0079] 2) Prepare a high temperature resistant insulating layer outside the stranded conductive wire core, the steps include mica tape wrapping, quartz fiber wrapping and quartz fiber weaving.

[0080] The mica tape used is made of mica paper and glass cloth bonded by high temperature resistant modified silicone resin paint. The mica tape used is 0.075×8mm and the coverage rate is 67%.

[0081] A high-speed wire wrapping machine is used to wrap the quartz fiber. The parameters of the quartz fiber package are: 4 strands, 250 strands per strand, and a covering rate of 5%;

[0082] Quartz fiber weaving is performed using a high-speed weaving machine. Quartz fiber weaving parameters...

Embodiment 3

[0099] 1) Multi-strand monofilament cores are twisted in the same direction to make conductive cores. The monofilament core used is a nickel-plated round copper wire, the volume percentage of the nickel layer is 15%, and the specification of the stranded conductive core is 127×0.300 (mm);

[0100] 2) Prepare a high temperature resistant insulating layer outside the stranded conductive wire core, the steps include mica tape wrapping, quartz fiber wrapping and quartz fiber weaving.

[0101] The mica tape used is made of mica paper and glass cloth bonded by high temperature resistant modified silicone resin paint. The mica tape used is 0.075×8mm and the coverage rate is 67%.

[0102] A high-speed wire wrapping machine is used to wrap the quartz fiber. The parameters of the quartz fiber package are: 4 strands, the number of each strand is 160, and the covering rate is 5%;

[0103] Quartz fiber weaving is performed using a high-speed weaving machine. Quartz fiber weaving paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com