Preparation method of porous oil-absorbing fiber with fluorescence response

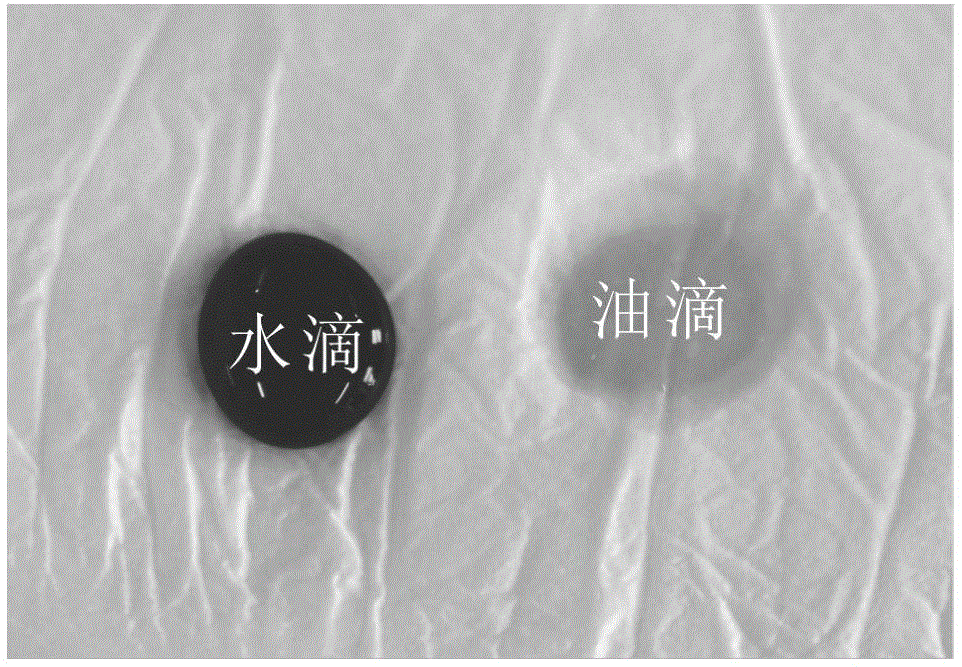

An oil-absorbing fiber, fluorescence response technology, applied in chemical characteristics of fibers, chemical instruments and methods, luminescent materials, etc., can solve problems such as single function, and achieve the effect of reduced fluorescence intensity, good oil absorption effect, and good fluorescence response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

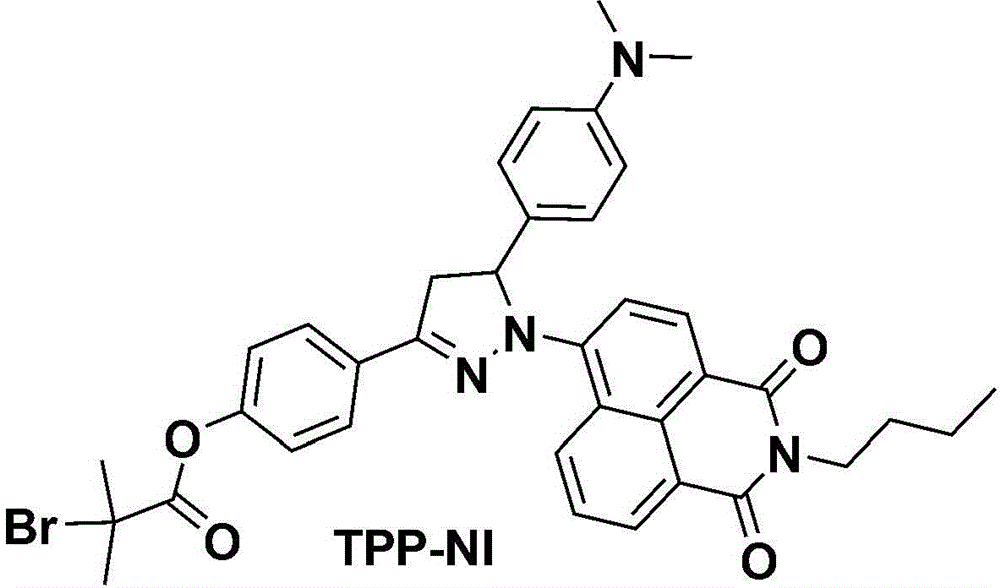

[0028] Example 1: The AIE effect polymer and its preparation method in this example are prior art (see: Chem.commun., 2012, 48, 10234-10236): firstly synthesize a small initiator molecule with AIE effect (naphthalene imide pyrazoline), its molecular structure is shown in figure 1 . Then through atom transfer radical polymerization, small molecules are grafted to the end of the polymer chain to obtain a polymer with AIE effect: polymethyl methacrylate;

[0029] Add 2 g of the synthesized polymethyl methacrylate powder with AIE effect to 4.6 g of N,N-dimethylformamide solvent, stir for 3 hours until it dissolves evenly, and prepare a spinning powder with a mass concentration of 30%. silk stock solution;

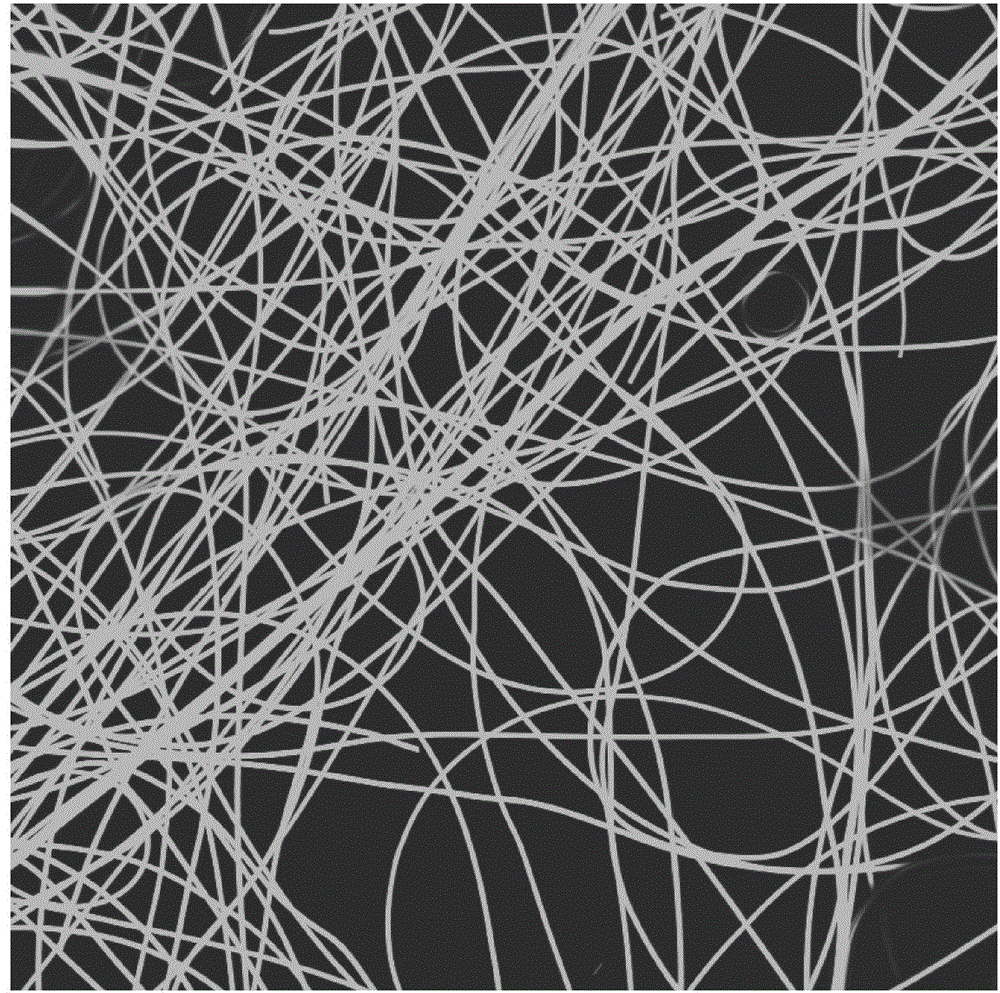

[0030] The above-mentioned spinning stock solution is prepared into porous oil-absorbing fibers by using an electrospinning process: in this embodiment, the specific parameters in the electrospinning process are limited as follows: add the spinning stock solution obtai...

Embodiment 2

[0031] Example 2: The AIE effect polymer and its preparation method in this example are prior art (see: Chem.commun., 2012, 48, 10234-10236): firstly synthesize a small initiator molecule with AIE effect (naphthalene imide pyrazoline), its molecular structure is shown in figure 1 . Then through atom transfer radical polymerization, small molecules are grafted to the end of the polymer chain to obtain a polymer with AIE effect: polystyrene;

[0032] Add 3 g of the synthesized polystyrene powder with AIE effect to 12 g of N,N-dimethylformamide solvent, stir for 3 hours until it dissolves evenly, and prepare a spinning stock solution with a mass concentration of 20%;

[0033] The above-mentioned spinning stock solution is prepared into porous oil-absorbing fibers by using an electrospinning process: in this embodiment, the specific parameters in the electrospinning process are limited as follows: add the spinning stock solution obtained above into a 10ml glass syringe, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com