High-performance hard alloy and manufacturing method thereof

A hard alloy, high-performance technology, applied in the field of powder metallurgy, can solve the problems that it is difficult to achieve uniform distribution of inhibitors, there is no ideal solution, and corrosion resistance cannot be achieved, so as to achieve good anti-oxidation effect and mechanical properties Good, high mechanical strength and plasticity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

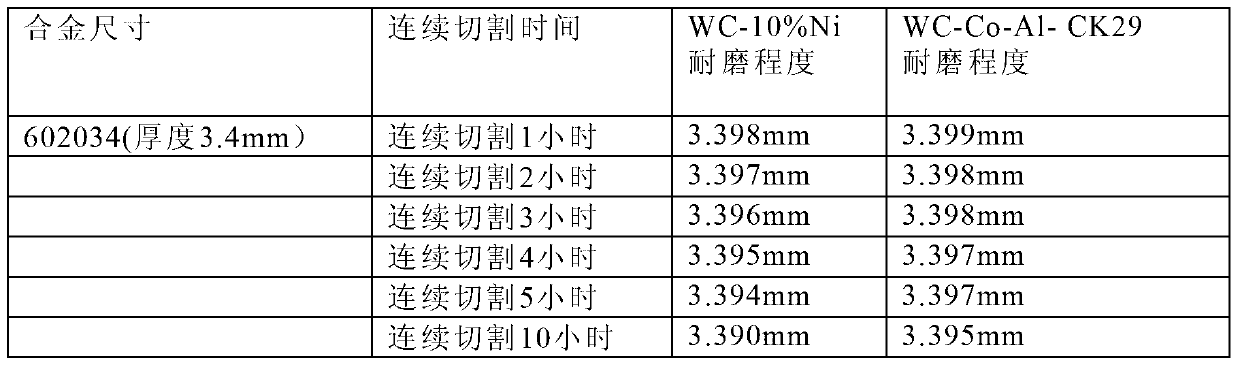

Embodiment 1

[0030] Example 1: 5% by weight of Co powder, 7% of Co-Al powder, 3% of CK29 powder, and the balance of WC powder are mixed according to requirements, and the alcohol is used as a wet grinding medium to grind in a high-energy ball mill for 67 Unload after 1 hour, then dry, mix with rubber and granulate, and then press to form the desired product shape, vacuum sinter at a temperature of 1430°C, and hold for 30 minutes to obtain high-performance cemented carbide products.

Embodiment 2

[0031] Example 2: 6% by weight of Co powder, 6% of Co-Al powder, 3.5% of CK29 powder, and the balance of WC powder are mixed according to requirements, and the alcohol is used as a wet grinding medium to grind in a high-energy ball mill for 70 Unload after 1 hour, then dry, mix with glue and granulate, then press to form the desired product shape, vacuum sinter at a temperature of 1435°C, and hold for 28 minutes to obtain a high-performance cemented carbide product.

Embodiment 3

[0032] Example 3: 7% by weight of Co powder, 6% of Co-Al powder, 4% of CK29 powder, and the balance of WC powder are mixed according to requirements, and the alcohol is used as a wet grinding medium to grind in a high-energy ball mill for 72 Unload after 1 hour, then dry, mix with glue and granulate, then press to form the desired product shape, vacuum sinter at a temperature of 1440°C, and hold for 26 minutes to obtain a high-performance cemented carbide product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com