Method for recovering silver from waste silver catalyst

A silver catalyst and slagging agent technology, applied in the field of silver recovery, can solve the problems of large environmental pollution, high silver content, and reduced silver recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

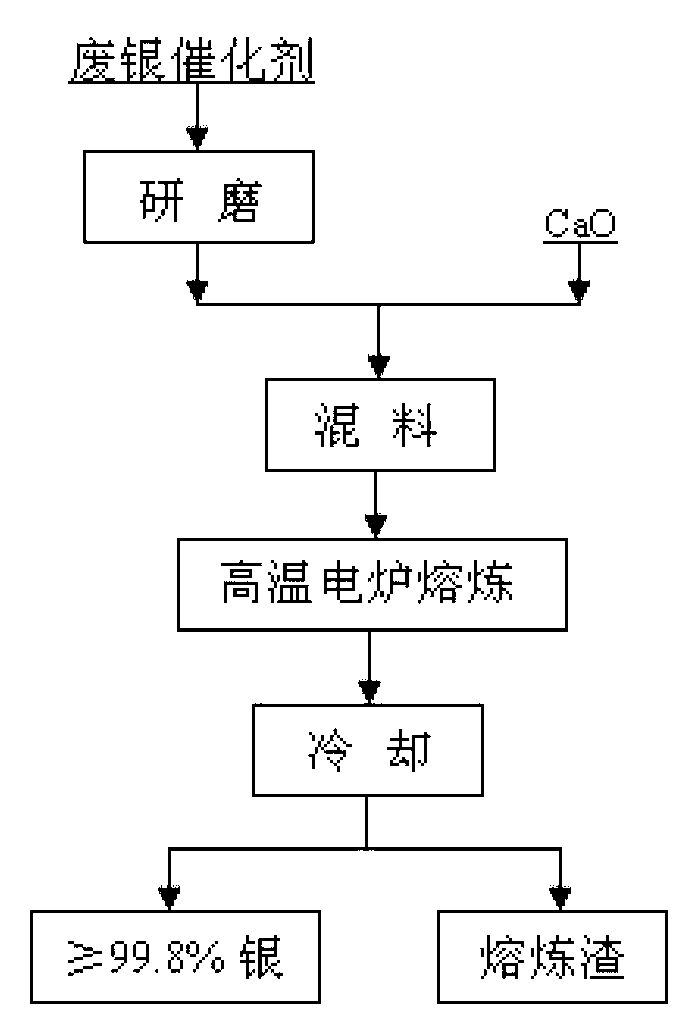

Image

Examples

Embodiment 1

[0024] The waste silver catalyst used in the oxidation of ethylene to ethylene oxide, supported by α-Al 2 o 3 , the silver content is 16.84%, and the alumina content is 83.16%. First grind the waste silver catalyst to 100 mesh, take 500 grams of the ground waste silver catalyst, add 420 grams of lime (CaO), mix well, put it into a graphite crucible, heat it in a silicon-molybdenum rod high-temperature box-type electric furnace, and raise the temperature To 1500 ℃, heat preservation for 5 hours, cooling to normal temperature, the slag phase and the metallic silver phase are separated to obtain 83.27 grams of silver, the recovery rate of silver is 98.9%, and the silver purity is greater than 99.8%.

Embodiment 2

[0026] Take 500 grams of the waste silver catalyst that has been ground in Example 1, add 420 grams of lime (CaO), mix well, put it into a graphite crucible, heat it in a silicon-molybdenum rod high-temperature box-type electric furnace, raise the temperature to 1550 ° C, and keep it warm for 5 Hour, be cooled to normal temperature, slag phase and metal silver phase separation, obtain 83.52 grams of silver, the rate of recovery of silver is 99.19%, and silver purity is greater than 99.8%.

Embodiment 3

[0028] Take 500 grams of the waste silver catalyst that has been ground in Example 1, add 420 grams of lime (CaO), mix well, put it into a graphite crucible, heat it in a silicon-molybdenum rod high-temperature box-type electric furnace, raise the temperature to 1600 ° C, and keep it warm for 5 Hour, be cooled to normal temperature, slag phase and metal silver phase separation, obtain 83.73 grams of silver, the rate of recovery of silver is 99.44%, and silver purity is greater than 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com