Method and device for preparing powdered iron through magnetizing low-iron red mud

A technology of magnetization treatment and iron powder, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of continuous and stable production, difficult process control, poor production continuity, etc., to ensure continuous long-term cycle. The effect of running, avoiding pulverization and segregation, and producing fast adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

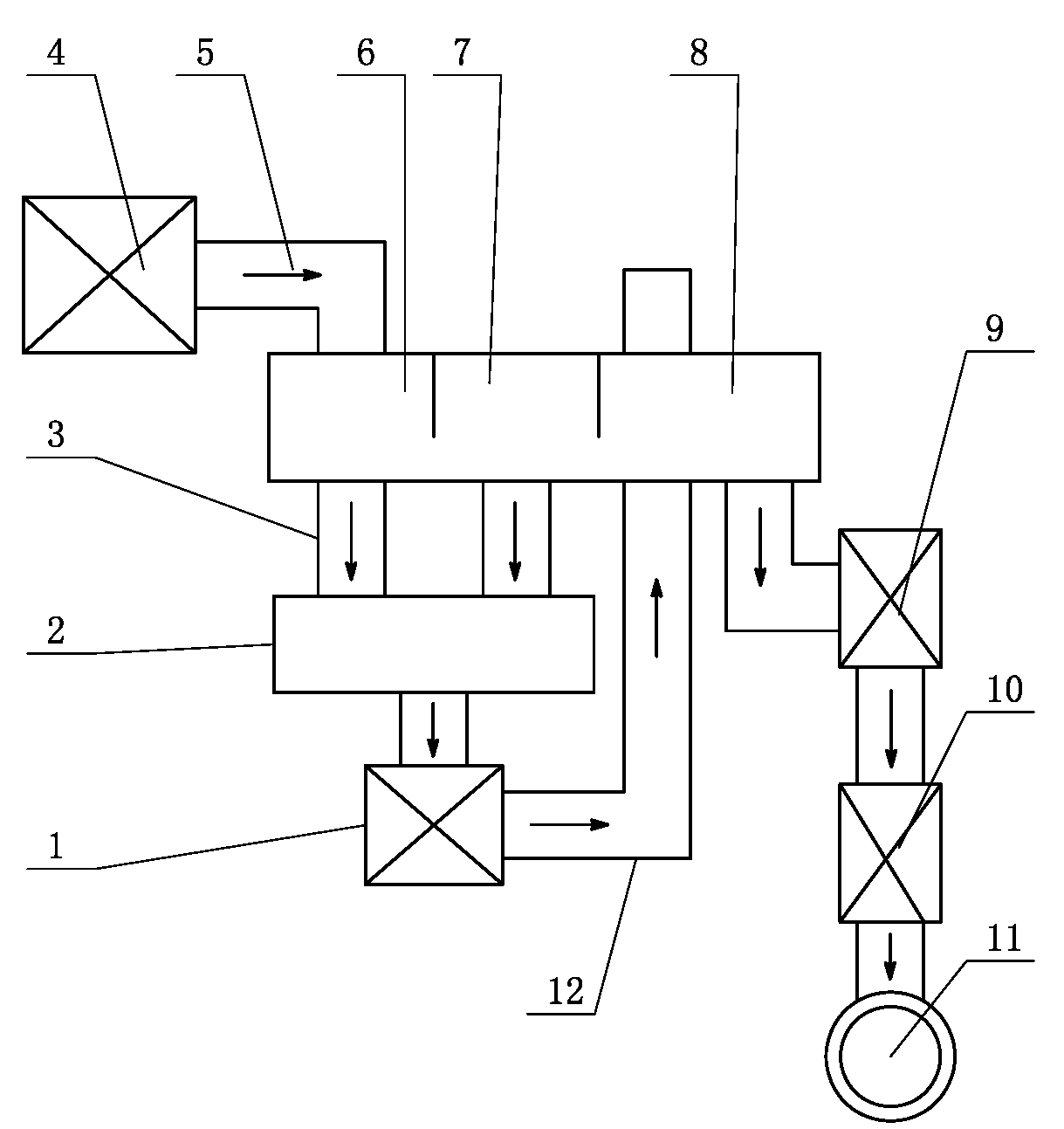

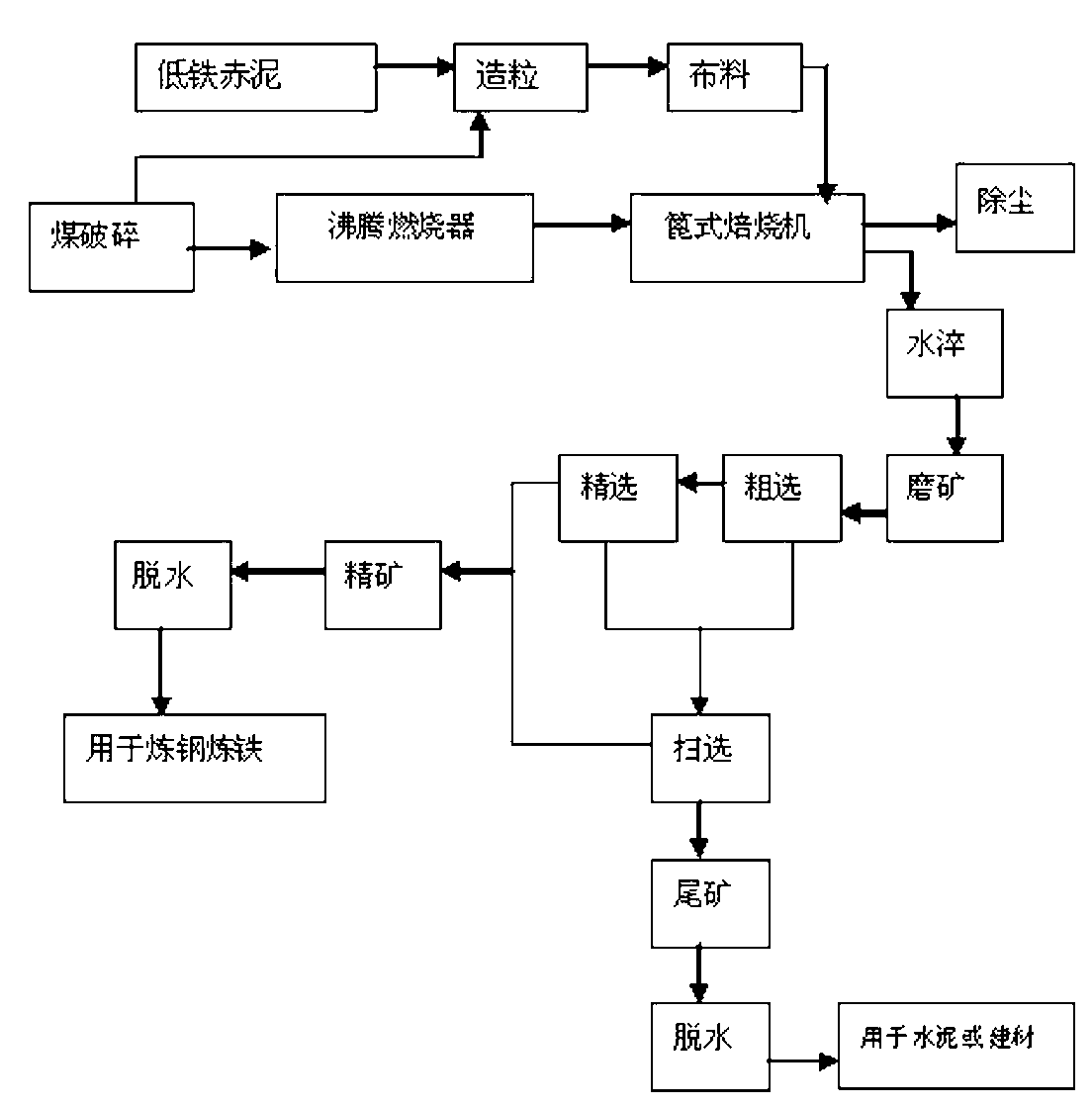

[0031] Such as figure 1 As shown, a device for magnetizing low-iron red mud to prepare iron powder, the core component of which is a grate roaster. The grate roaster includes three parts: a roasting section 6, a preheating section 7 and a drying section 8. The roasting section 6. A retaining wall is set between the preheating section 7 and the drying section 8. The roasting section 6 and the preheating section 7 are connected to the gas collecting pipe 2 through the air passage 3, and the gas collecting pipe 2 is connected to the drying section 8 through the fan 1 and the fan pipeline 12; the conveying grate bed of the grate roaster runs through the roasting section 6 and the preheating section 7 and drying section 8. The calcination temperatures of the calcination section 6, the preheating section 7 and the drying section 8 are 650°C, 550°C, and 250°C, respectively.

[0032] The boiling burner 4 is connected to the roasting section 6 through the hot flue gas channel 5 .

...

Embodiment 2

[0050] The calcination temperature of the calcination section 6 is 680° C., correspondingly, the calcination temperature of the materials in the calcination stage is 680° C. respectively. The reducing agent is lignite or low-quality bituminous coal with a fixed carbon content of 40%, and the molar ratio of the fixed carbon content to the total oxygen content in the reducing agent is C / O=0.95. Other technical features are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0052] The calcination temperature of the calcination section 6 is 660° C., correspondingly, the calcination temperature of the materials in the calcination stage is 660° C. respectively. The reducing agent is lignite or low-quality bituminous coal with a fixed carbon content of 40%, and the molar ratio of the fixed carbon content to the total oxygen content in the reducing agent is C / O=0.92. Other technical features are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com