Preparation method of rare earth molybdate matrix red nanophosphor

A nano-phosphor, molybdate technology, applied in chemical instruments and methods, luminescent materials, etc., to achieve uniform particles, good reproducibility, and stable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) reacting lanthanum nitrate and europium nitrate with stearic acid to generate a stearate precursor of rare earth ions, the molar fraction of europium ions in the precursor being 10% of the total rare earth ions;

[0022] (2) 2 milliliters of oleic acid and 2 milliliters of oleylamine are stirred and dissolved in isopropanol solvent, and then the rare earth stearate precursor with a total mole number of 0.50 mmol is added, stirred and dissolved to obtain the rare earth stearate precursor solid isopropanol solution;

[0023] (3) 0.75 mmol of sodium molybdate was dissolved in water, then slowly added dropwise to the isopropanol solution in which 1.5 mmol of tetraoctyl ammonium bromide was dissolved, stirred and reacted for 10 minutes to obtain the isopropanol solution of sodium molybdate solution;

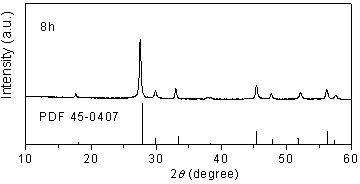

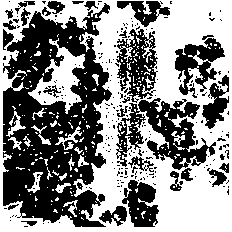

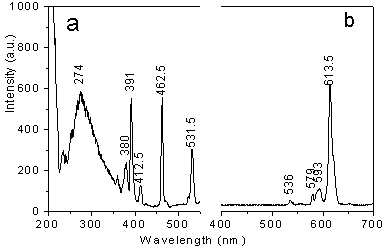

[0024] (4) Mix the isopropanol solution of the rare earth stearate precursor with the isopropanol solution of sodium molybdate, transfer it to the reaction kettle, seal it...

Embodiment 2

[0027] (1) reacting lanthanum nitrate and europium nitrate with stearic acid to generate a stearate precursor of rare earth ions, the molar fraction of europium ions in the precursor being 10% of the total rare earth ions;

[0028] (2) 2 milliliters of oleic acid and 2 milliliters of oleylamine are stirred and dissolved in isopropanol solvent, and then the rare earth stearate precursor with a total mole number of 0.50 mmol is added, stirred and dissolved to obtain the rare earth stearate precursor solid isopropanol solution;

[0029] (3) 0.75 mmol of sodium molybdate was dissolved in water, then slowly added dropwise to the isopropanol solution in which 1.5 mmol of tetraoctyl ammonium bromide was dissolved, stirred and reacted for 10 minutes to obtain the isopropanol solution of sodium molybdate solution;

[0030] (4) Mix the isopropanol solution of the rare earth stearate precursor with the isopropanol solution of sodium molybdate, transfer it to the reaction kettle, sea...

Embodiment 3

[0032] (1) reacting yttrium nitrate and europium nitrate with stearic acid to generate a stearate precursor of rare earth ions, the molar fraction of europium ions in the precursor being 5% of the total rare earth ions;

[0033] (2) 2 milliliters of oleic acid and 2 milliliters of oleylamine were stirred and dissolved in isopropanol solvent, then added the rare earth stearate precursor with a total mole number of 1.0 mmol, stirred and dissolved to obtain the rare earth stearate precursor solid isopropanol solution;

[0034] (3) 0.75 mmol of sodium molybdate was dissolved in water, then slowly added dropwise to the isopropanol solution in which 1.5 mmol of tetraoctyl ammonium bromide was dissolved, stirred and reacted for 10 minutes to obtain the isopropanol solution of sodium molybdate solution;

[0035] (4) Mix the isopropanol solution of the rare earth stearate precursor with the isopropanol solution of sodium molybdate, transfer it to the reaction kettle, seal it, and heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com