Method for modulating titanium dioxide crystalline phases by using fluoride ions

A titanium dioxide and fluoride ion technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of complex process, high reaction temperature and high energy consumption, and achieve the effects of simple process, mild reaction conditions and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

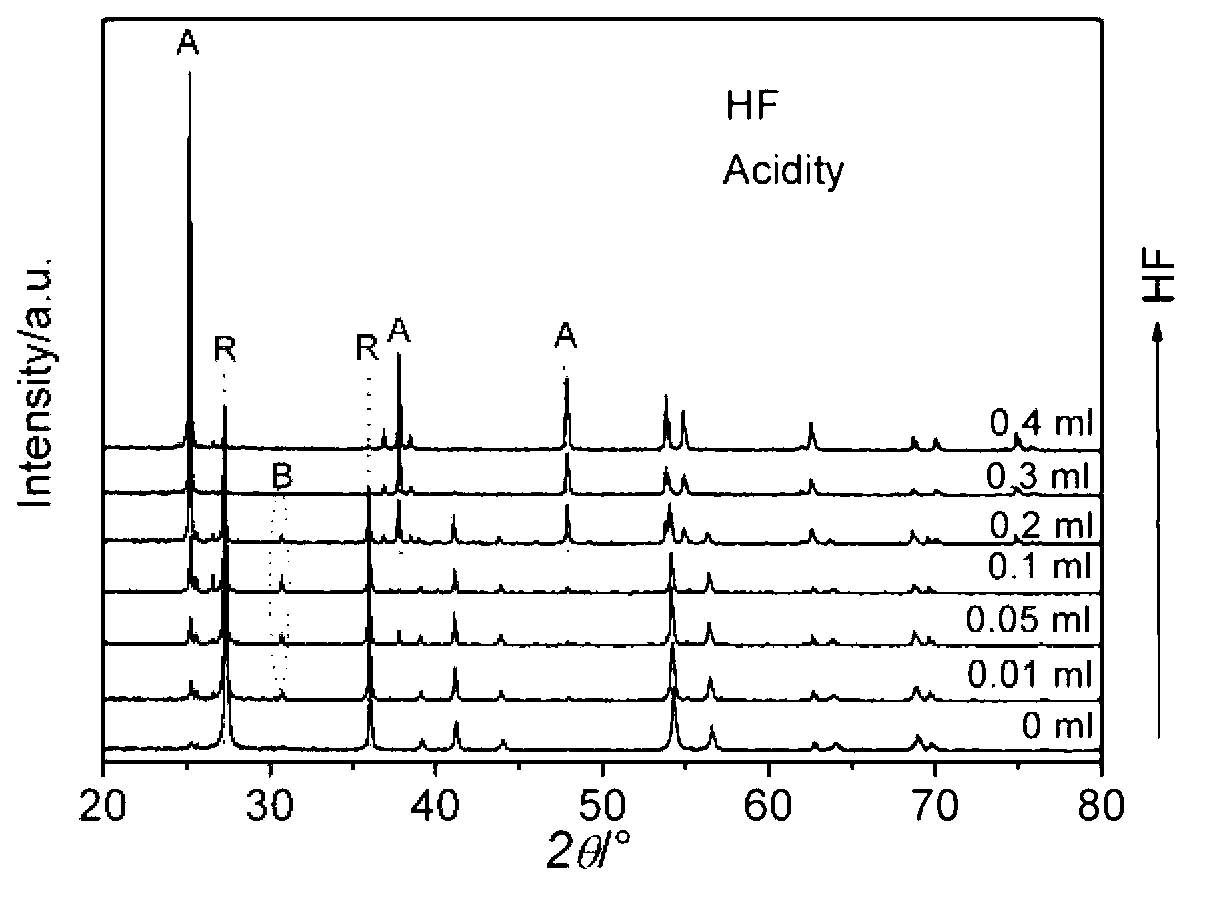

[0038] This embodiment provides a method for adjusting the crystal phase of titanium dioxide using fluoride ions, which includes the following steps:

[0039] Add 0.1g of titanium powder (200 mesh) into 30mL of HCl solution with a concentration of 2mol / L to obtain a suspension solution, and stir for 15min;

[0040] Then, 0 mL (as a comparison), 0.01 mL, 0.05 mL, 0.1 mL, 0.2 mL, 0.3 mL, and 0.4 mL of HF solution with a concentration of 5 mol / L were added to the seven suspension solutions to obtain seven parts of the reaction mixture. Quickly transfer to a 50mL autoclave with a Teflon liner;

[0041] Transfer the high-pressure reactor to an electric oven, heat the reaction mixture to 220°C and keep it for 12 hours for crystallization;

[0042] After the crystallization treatment is completed, the reaction mixture is cooled to room temperature, filtered, washed with water, and dried at 50°C to obtain a solid product;

[0043] Finally, the solid product was treated with NaOH solut...

Embodiment 2

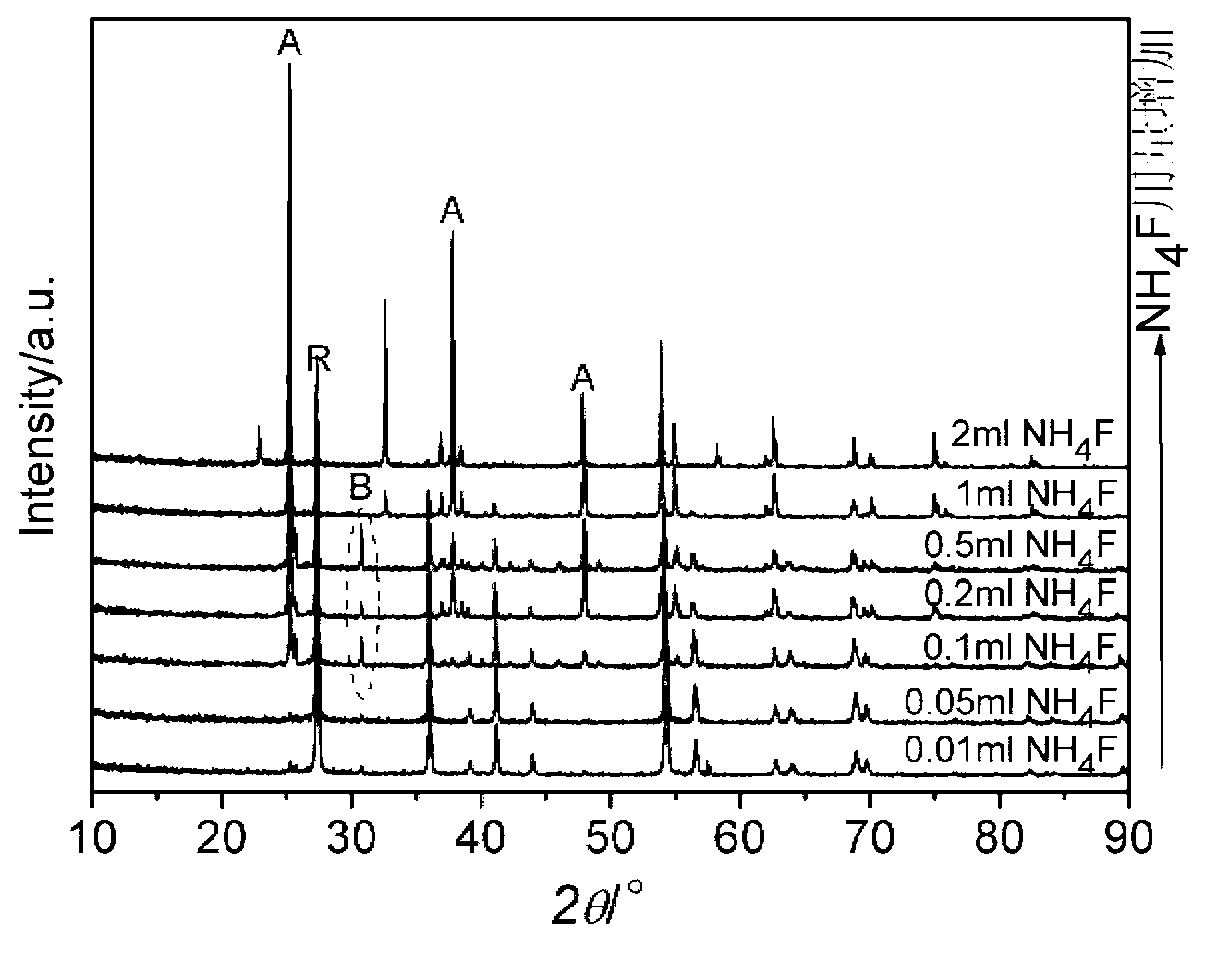

[0047] This embodiment provides a method for adjusting the crystal phase of titanium dioxide using fluoride ions, which includes the following steps:

[0048] Add 0.1g of titanium powder (200 mesh) into 30mL of HCl solution with a concentration of 2mol / L to obtain a suspension solution, and stir for 15min;

[0049] Then, 0.01mL, 0.05mL, 0.1mL, 0.2mL, 0.5mL, 1mL, and 2mL of NH4F solutions with a concentration of 5mol / L were added to the seven suspension solutions to obtain seven reaction mixtures, which were quickly transferred to 50mL autoclave with PTFE lining;

[0050] Transfer the high-pressure reactor to an electric oven, heat the reaction mixture to 220°C and keep it for 12 hours for crystallization;

[0051] After the crystallization treatment is completed, the reaction mixture is cooled to room temperature, filtered, washed with water, and dried at 50°C to obtain a solid product;

[0052] Finally, the solid product was treated with NaOH solution with a concentration o...

Embodiment 3

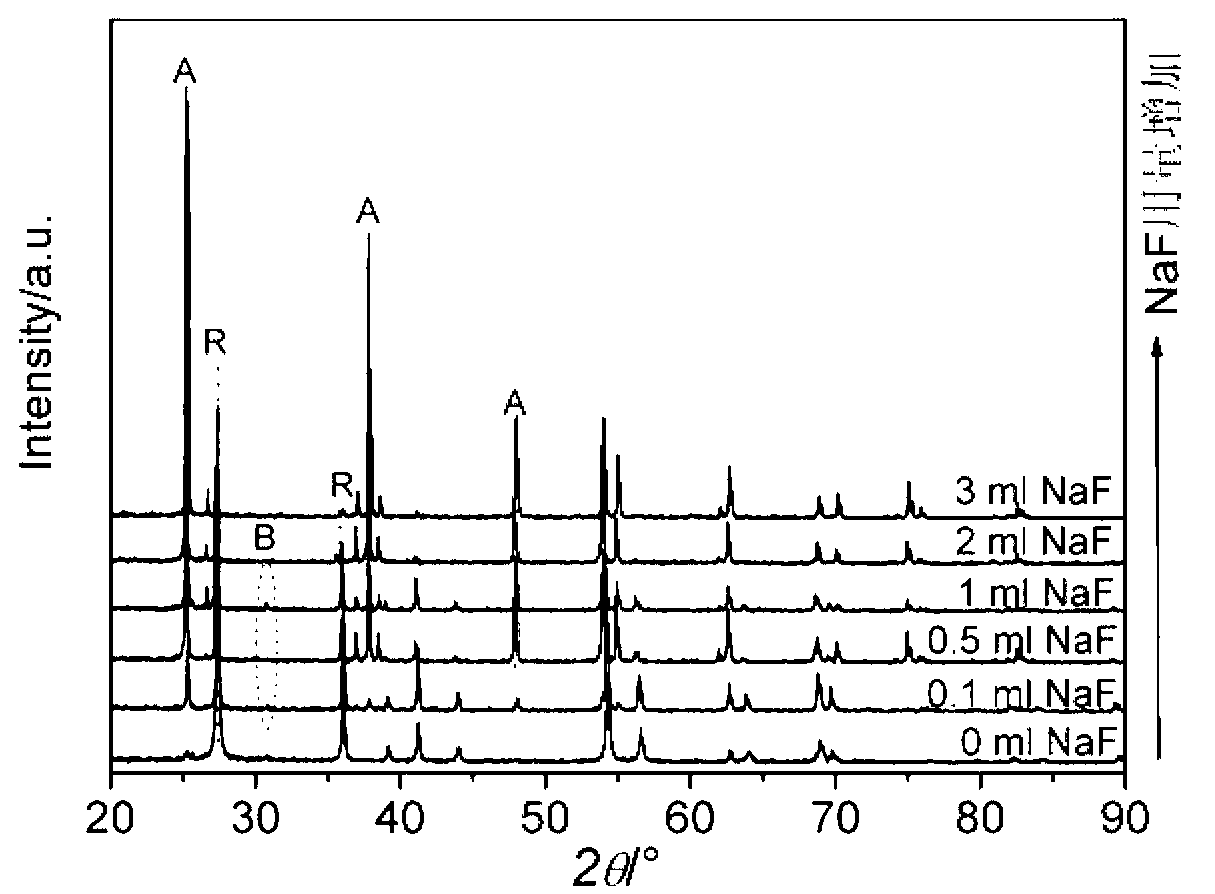

[0056] This embodiment provides a method for adjusting the crystal phase of titanium dioxide using fluoride ions, which includes the following steps:

[0057] Add 0.1g of titanium powder (200 mesh) into 30mL of HCl solution with a concentration of 2mol / L to obtain a suspension solution, and stir for 15min;

[0058] Then, 0 mL (as a comparison), 0.1 mL, 0.5 mL, 1 mL, 2 mL, and 3 mL of NaF solution with a concentration of 5 mol / L were added to the seven suspension solutions to obtain six reaction mixtures, which were quickly transferred to a volume of 50 mL. In a high-pressure reactor with a PTFE liner;

[0059] Transfer the high-pressure reactor to an electric oven, heat the reaction mixture to 220°C and keep it for 12 hours for crystallization;

[0060] After the crystallization treatment is completed, the reaction mixture is cooled to room temperature, filtered, washed with water, and dried at 50°C to obtain a solid product;

[0061] Finally, the solid product was treated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com