Method for surface treatment of aluminium alloy and product of aluminium alloy

A technology of aluminum alloy surface and treatment method, applied in special artistic surface treatment, copy/marking method, surface reaction electrolytic coating, etc., can solve the problem of only one kind of sand texture, etc., to improve sandblasting resistance and beautiful appearance Versatile, more layered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

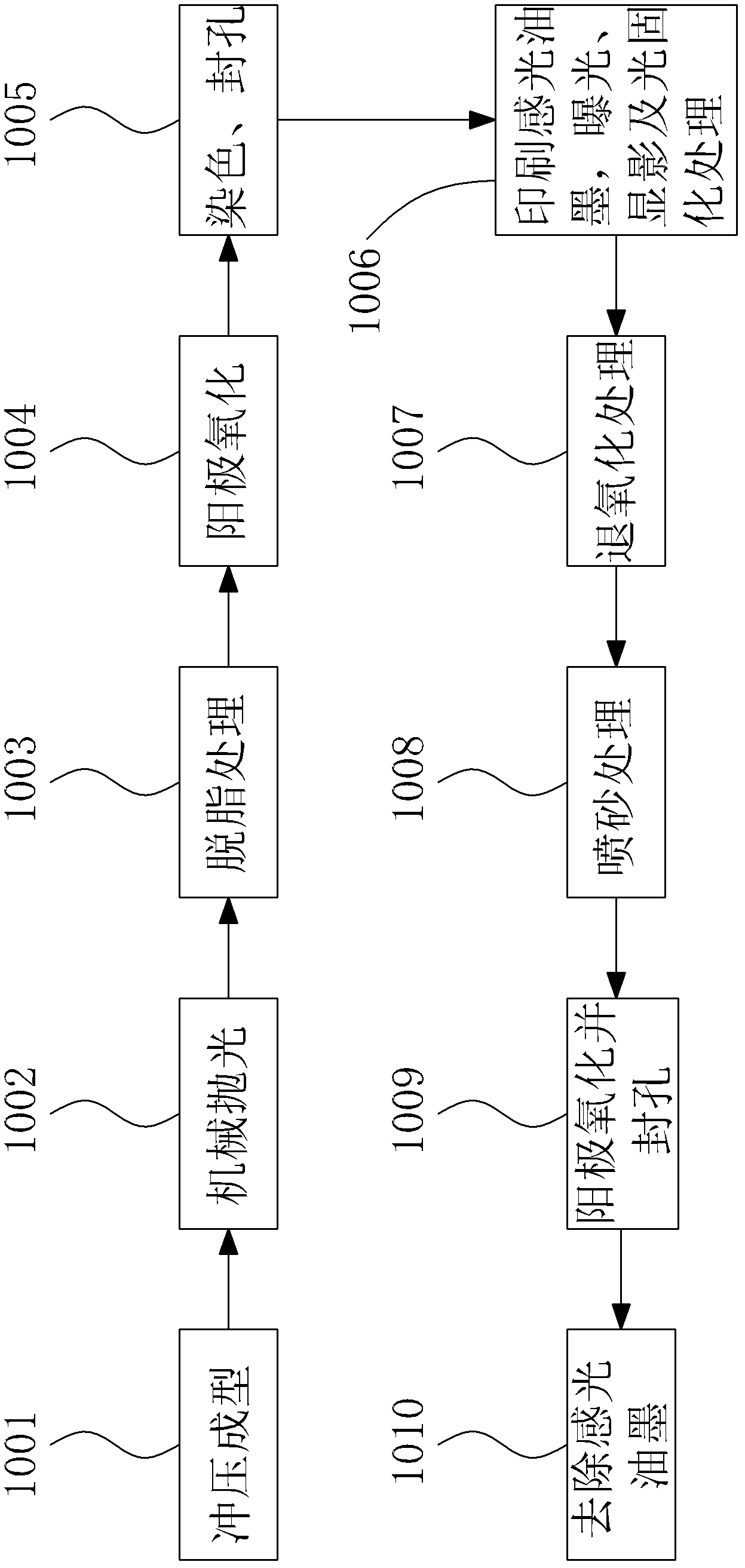

[0031] For a further understanding of the purpose of the present invention, method steps and functions, please refer to figure 1 , and detailed as follows:

[0032] The invention provides a method for surface treatment of an aluminum alloy, which comprises the following steps:

[0033] Step 1001: Stamping the aluminum alloy into a desired shape, the aluminum alloy can be a series of 1 or series 2 or series 5 or series 6 or series 7;

[0034] Step 1002: mechanically polishing the stamped aluminum alloy to achieve a mirror effect;

[0035] Step 1003: Degrease the mechanically polished aluminum alloy in a degreasing agent with a concentration of 5% to 8%, to remove surface grease and polishing wax; perform light treatment on the degreased aluminum alloy to remove the surface oxide film, and perform light treatment The final aluminum alloy is neutralized, and the neutralization treatment uses a nitric acid solution with a concentration of 20-40% to remove the hydroxide black ash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com