High-nitrogen austenitic stainless steel for vascular stent and application thereof

A nitrogen austenitic and vascular stent technology, applied in the field of high nitrogen austenitic stainless steel, can solve the problems of poor visibility and poor austenite stability, and achieve the advantages of increasing density, reducing restenosis rate, improving and optimizing elasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

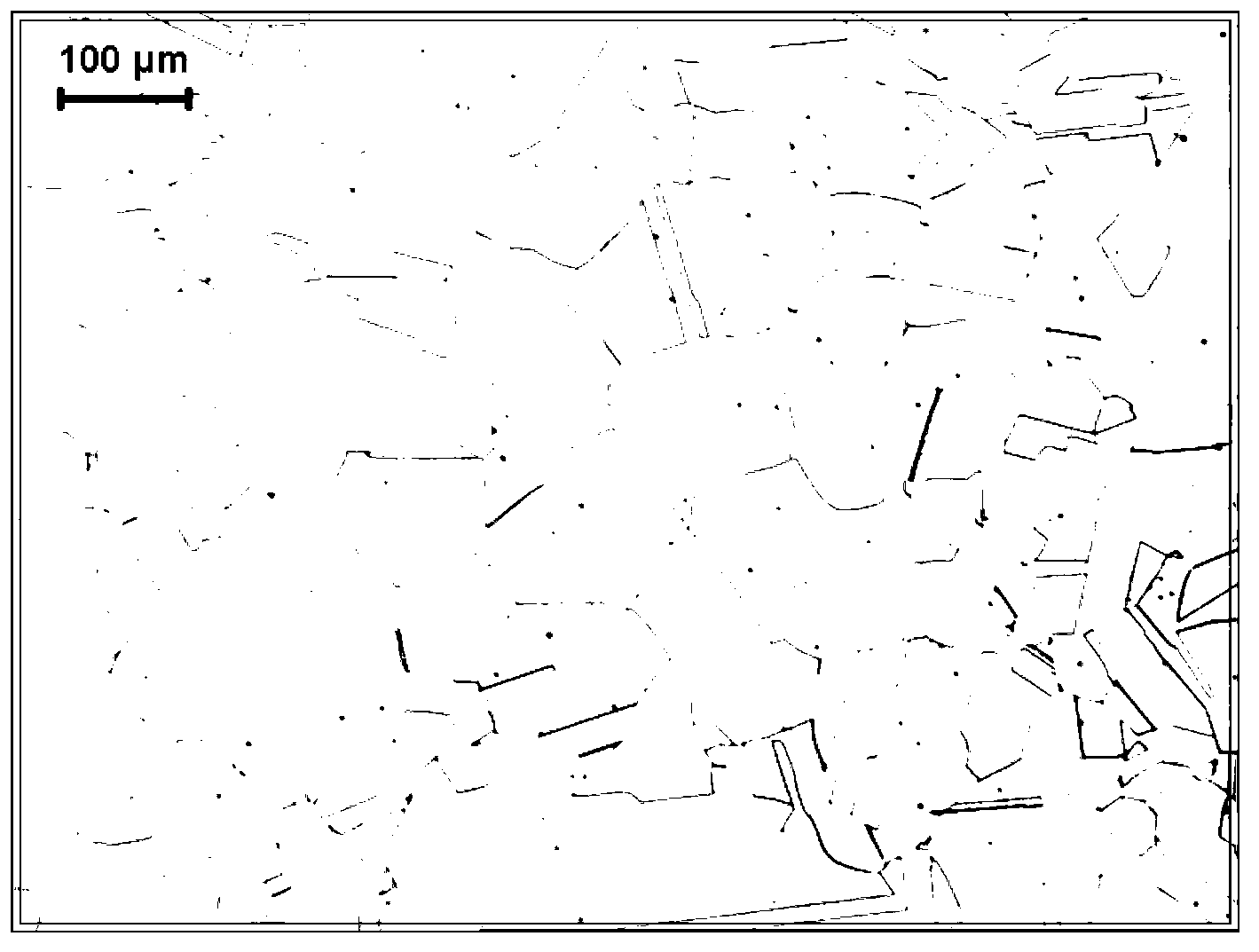

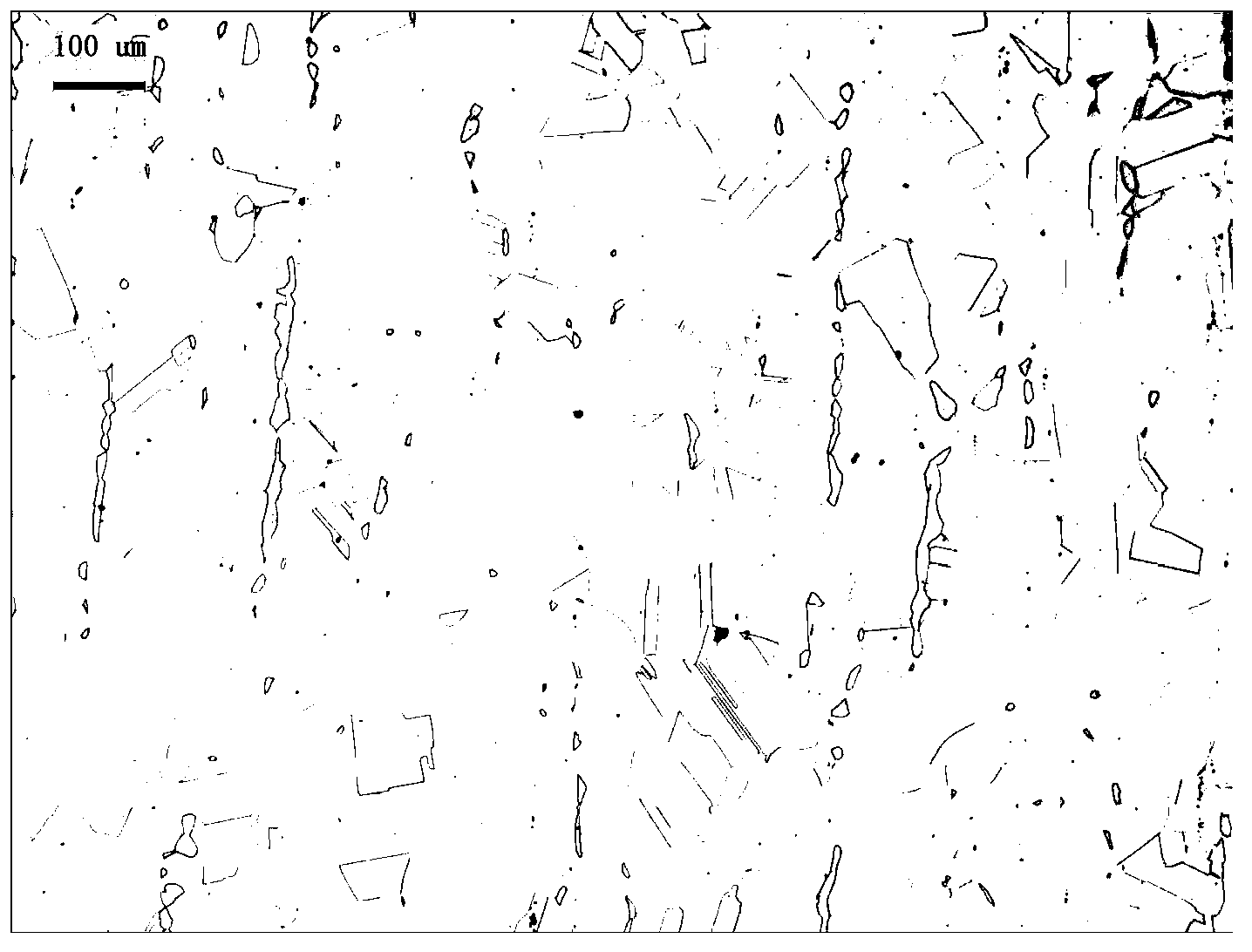

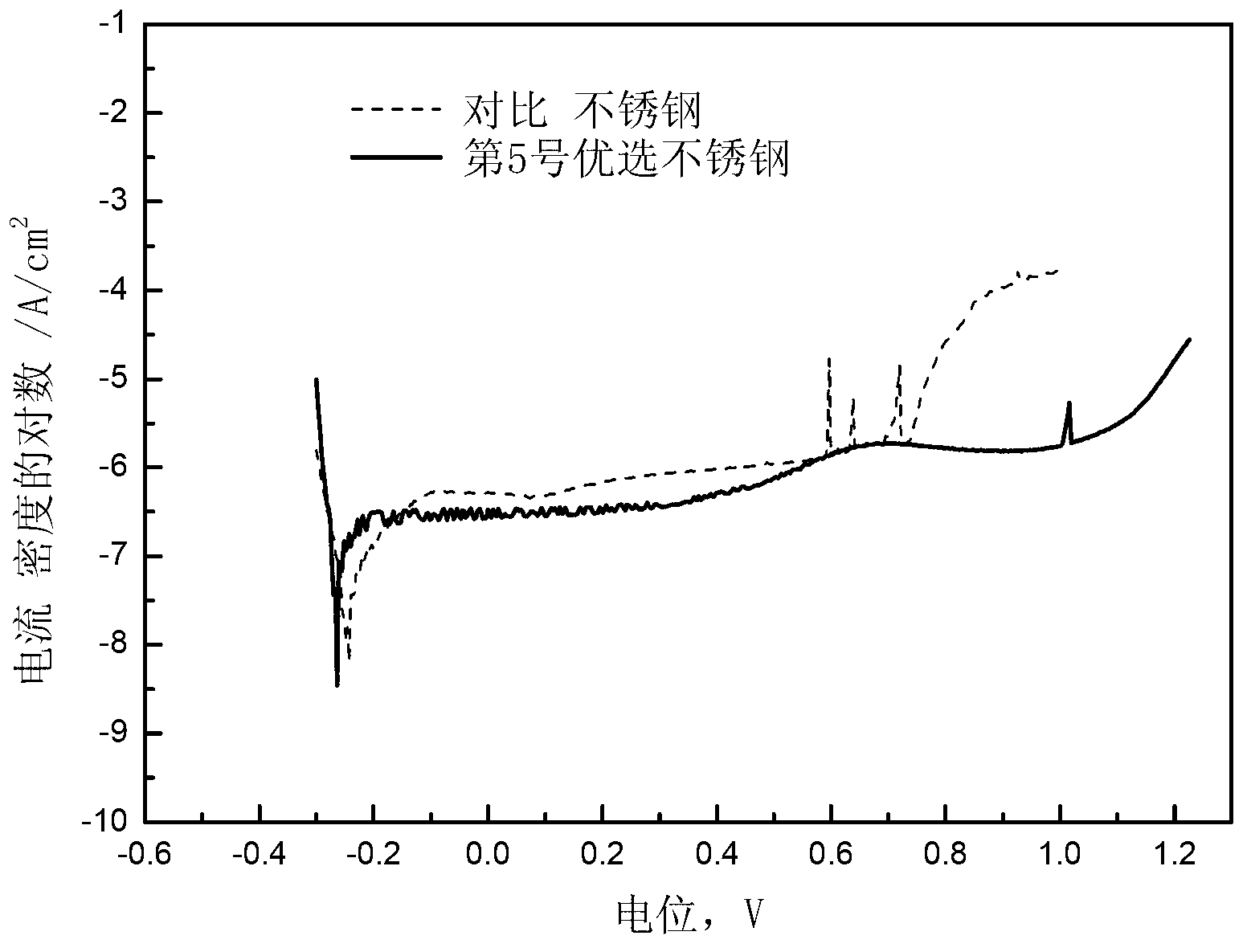

[0033] According to the chemical composition range set by the high-nitrogen stainless steel of the present invention, 5 furnaces of steel (respectively numbered 1-5) and 20 kg of comparative stainless steel were smelted in a pressurized induction furnace with 50 kg, and the specific chemical composition is shown in Table 1. The protective nitrogen pressure is 0.5MPa, 0.6MPa, 1MPa and 0.8MPa, 0.7MPa respectively, and the nitrided alloy is MnN with a nitrogen content of 6% (wt%). These 6 heats of steel are respectively poured into a φ100×350 steel ingot. , according to the following processing and heat treatment process specifications for processing.

[0034] The forging process is as follows: the alloy ingot is homogenized and heat-treated at 1150°C±15°C for 2 hours to open the billet, and is forged in three fires to form a rough billet, and the final forging temperature is 950°C.

[0035] The hot-rolling process is as follows: the first-rolled billet is kept at a temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com