Molecular imprinting polymer for roxarsone detection, and preparation method thereof

A molecular imprinting and polymer technology, applied in the field of materials chemistry, can solve the problems of weak specificity, lack of selectivity, affecting the sensitivity and accurate quantification of detection methods, and achieve strong specific recognition ability, high affinity and selection. sex, improve specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

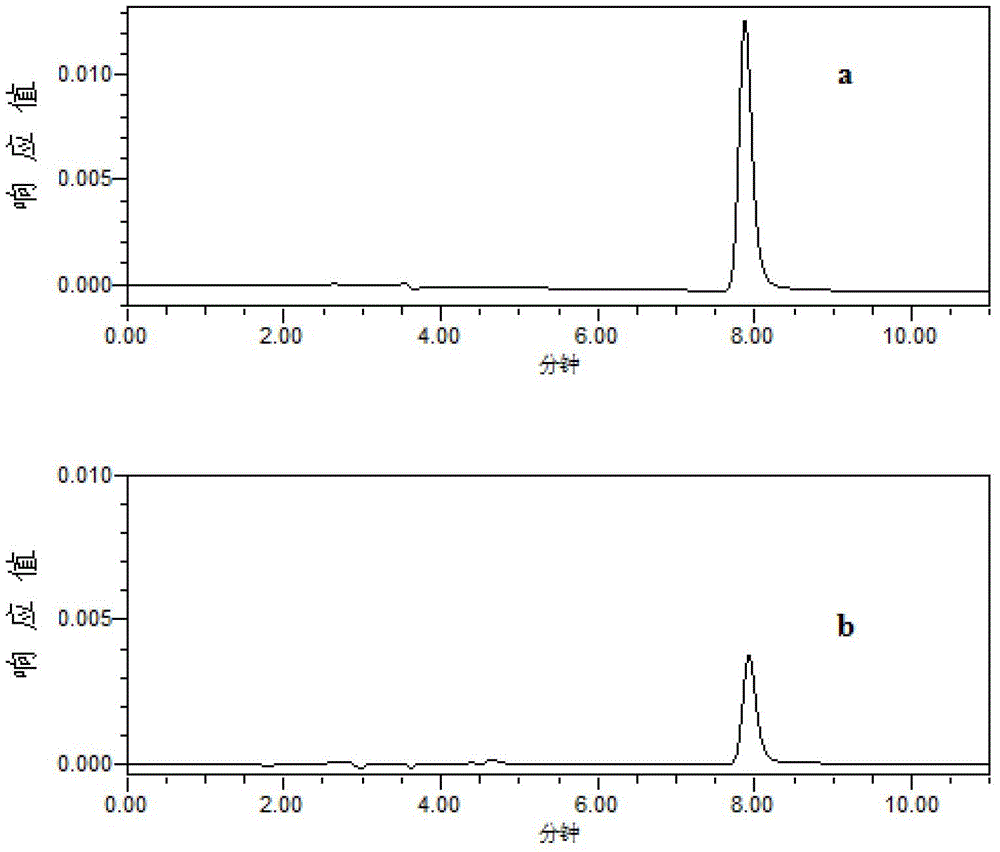

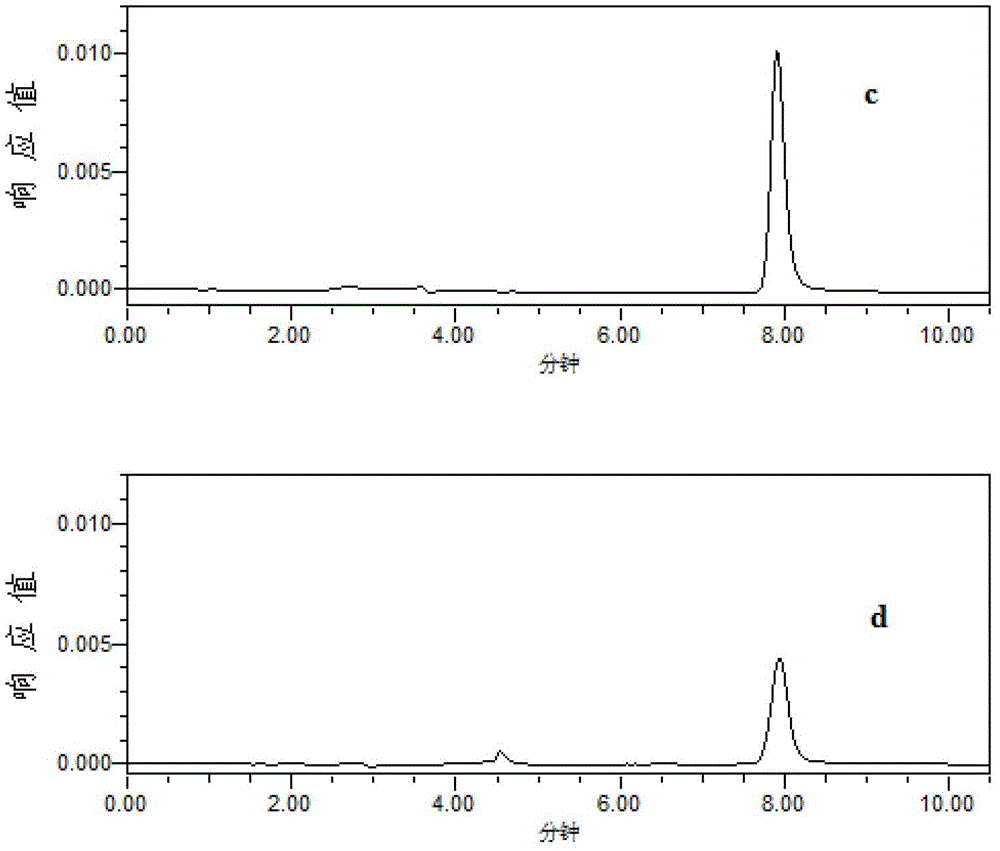

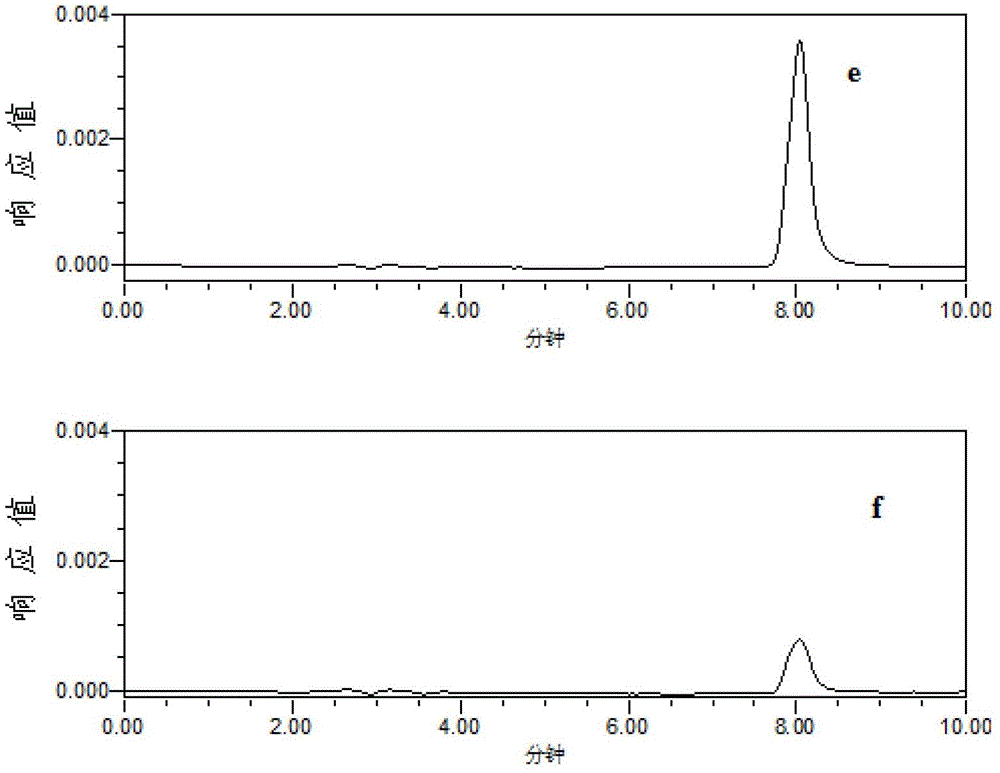

Image

Examples

Embodiment 1

[0048] (1) Weigh 0.166g (1mmoL) of ethyl p-hydroxybenzoate into a test tube, add 1mL of acetonitrile, vortex to dissolve, then add 0.434mL (4mmoL) of 2-vinylpyridine functional monomer, sonicate for 5min, and let stand for 1h , forming a prepolymer.

[0049] (2) Add 4mL (20mmoL) of ethylene glycol dimethacrylate and 60mg (0.365mmol) of azobisisobutyronitrile to the above prepolymer, sonicate for 5min, pass nitrogen gas for 5min under ice bath, seal, and vacuum at 60°C Polymerized in a dry box for 24 hours to obtain block polymer.

[0050] (3) Grind the above-mentioned massive polymer, pass through a 200-mesh sieve, and repeatedly settle with methanol to remove fine particles, put it into a 15mL solid-phase extraction column, and first use a mixed solution of acetic acid and methanol (the volume ratio of acetic acid and methanol is 1 : 9) Wash with 200mL to remove the template ethyl p-hydroxybenzoate, control the flow rate below 1mL / min, wash with 40mL of methanol to remove ac...

Embodiment 2

[0053] (1) Weigh 0.217g (1mmoL) of arsanic acid into a test tube, add 6mL of methanol-acetonitrile solution (the volume ratio of methanol to acetonitrile is 1:1), vortex to dissolve, then add 0.434mL (4mmoL) of 2-ethylene Pyridine functional monomer, ultrasonic 5min, stand for 1h to form a pre-polymer.

[0054] (2) Add 4mL (20mmoL) of ethylene glycol dimethacrylate and 60mg (0.365mmol) of azobisisobutyronitrile to the above prepolymer, sonicate for 5min, pass nitrogen gas for 5min under ice bath, seal, and vacuum at 60°C Polymerized in a dry box for 24 hours to obtain block polymer.

[0055] (3) Grind the above-mentioned massive polymer, pass through a 200-mesh sieve, and repeatedly settle with methanol to remove fine particles, put it into a 15mL solid-phase extraction column, and first use a mixed solution of acetic acid and methanol (the volume ratio of acetic acid and methanol is 1 : 9) Wash with 200mL to remove the template arsanic acid, control the flow rate below 1mL / m...

Embodiment 3

[0058] (1) Weigh 0.217g (1mmoL) of arsanic acid into a test tube, add 6mL of methanol-acetonitrile (1:1, V / V) solution, vortex to dissolve, then add 0.171mL (2mmoL) of methacrylic acid functional monomer , sonicated for 5 minutes, and allowed to stand for 1 hour to form a prepolymer.

[0059] (2) Add 3.19mL (10mmoL) of trimethylolpropane trimethacrylate and 10mg (0.06mmoL) of azobisisobutyronitrile to the above prepolymer, sonicate for 5min, blow nitrogen gas for 5min under ice bath, seal, Polymerize in a vacuum oven at 50°C for 48 hours to obtain block polymer.

[0060] (3) Grind the above-mentioned massive polymer, pass through a 200-mesh sieve, and repeatedly settle with methanol to remove fine particles, put it into a 15 mL solid-phase extraction column, and first use a mixed solution of acetic acid and methanol (1:9, V / V ) 200mL to remove the template arsanic acid, the flow rate was controlled below 1mL / min, then washed with 40mL methanol to remove acetic acid, and dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com