Salt-corrosion-resistant torsion-resistant cable insulating rubber for marine wind power and manufacturing method thereof

A technology of cable insulation and insulating rubber, which is applied in the manufacture of salt-rot-resistant and torsion-resistant cable insulating rubber for offshore wind power, and in the field of salt-rot-resistant and torsion-resistant cable insulating rubber for offshore wind power, which can solve the problem that is not conducive to the insulation and sheath of cable ends Separation, not suitable for marine wind power environment, no seawater salt resistance, seawater moisture resistance and other problems, to achieve the effect of inhibiting the aging of copper conductors, reducing the current transmission capacity, and excellent extrusion process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

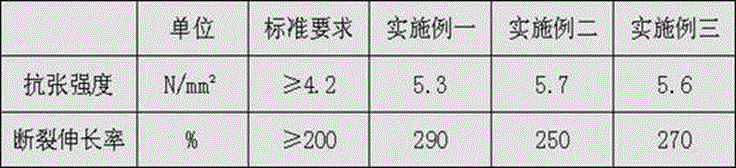

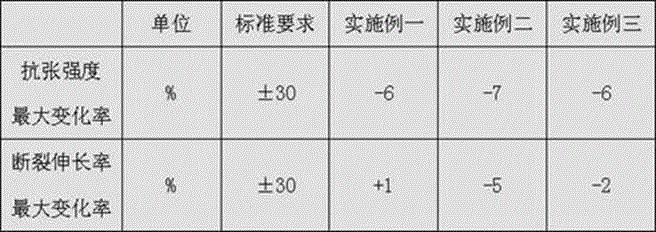

Embodiment 1

[0021] The manufacturing method of the salt-rot-resistant and torsion-resistant cable insulating rubber for marine wind power of the present invention comprises the following steps in sequence: (1) Prepare raw materials according to the following components and weight content, EPDM rubber Keltan 5508: 8 parts; EPDM Propylene rubber Dutral TER4044: 12 parts; granular ethylene elastomer rubber EP-20: 5 parts; vulcanizing agent dicumyl peroxide (curing agent DCP): 0.5 parts; co-vulcanizing agent triallyl cyanurate (co- Vulcanizing agent TAC): 0.3 parts; anti-scorch agent N, N'-m-phenylene bismaleimide (anti-scorch agent HVA-2): 0.2 parts; anti-aging agent 2,2,4-trimethyl-1 , 2-dihydroquinoline polymer (antiaging agent RD): 0.2 parts; antiaging agent 2-mercaptobenzimidazole (antiaging agent MB): 0.2 parts; silane coupling agent γ-aminopropyl triethoxy Silane (silane coupling agent KH-550): 0.2 parts; flame retardant zinc borate hydrate: 2.1 parts; flame retardant antimony trioxide...

Embodiment 2

[0025] The manufacturing method of the salt-rot-resistant and torsion-resistant cable insulating rubber for marine wind power of the present invention comprises the following steps in sequence: (1) Prepare raw materials according to the following components and weight content, EPDM rubber Keltan 5508: 8 parts; EPDM Propylene rubber Dutral TER4044: 12 parts; granular ethylene elastomer rubber EP-20: 6 parts; vulcanizing agent dicumyl peroxide: 0.6 parts; co-vulcanizing agent triallyl cyanurate: 0.4 parts; N,N'-m-phenylene bismaleimide: 0.3 parts; anti-aging agent 2,2,4-trimethyl-1,2-dihydroquinoline polymer: 0.3 parts; anti-aging agent 2-thiol Benzimidazole: 0.3 parts; silane coupling agent γ-aminopropyltriethoxysilane: 0.3 parts; flame retardant zinc borate hydrate: 2.3 parts; flame retardant antimony trioxide: 1.2 parts; flame retardant filling Agent aluminum hydroxide: 30 parts; Activator trilead tetraoxide: 1.0 part; Activator stearic acid: 0.8 part; Activator nano zinc oxi...

Embodiment 3

[0029] The manufacturing method of the salt-rot-resistant and torsion-resistant cable insulating rubber for marine wind power of the present invention comprises the following steps in sequence: (1) Prepare raw materials according to the following components and weight content, EPDM rubber Keltan 5508: 8 parts; EPDM Propylene rubber Dutral TER4044: 12 parts; granular ethylene elastomer rubber EP-20: 7 parts; vulcanizing agent dicumyl peroxide: 0.7 parts; co-vulcanizing agent triallyl cyanurate: 0.5 parts; N,N'-m-phenylene bismaleimide: 0.4 parts; anti-aging agent 2,2,4-trimethyl-1,2-dihydroquinoline polymer: 0.4 parts; anti-aging agent 2-thiol Benzimidazole: 0.4 parts; silane coupling agent γ-aminopropyltriethoxysilane: 0.4 parts; flame retardant zinc borate hydrate: 2.5 parts; flame retardant antimony trioxide: 1.5 parts; flame retardant filling Agent aluminum hydroxide: 40 parts; Activator trilead tetraoxide: 1.2 parts; Activator stearic acid: 1 part; Activator nano zinc oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com