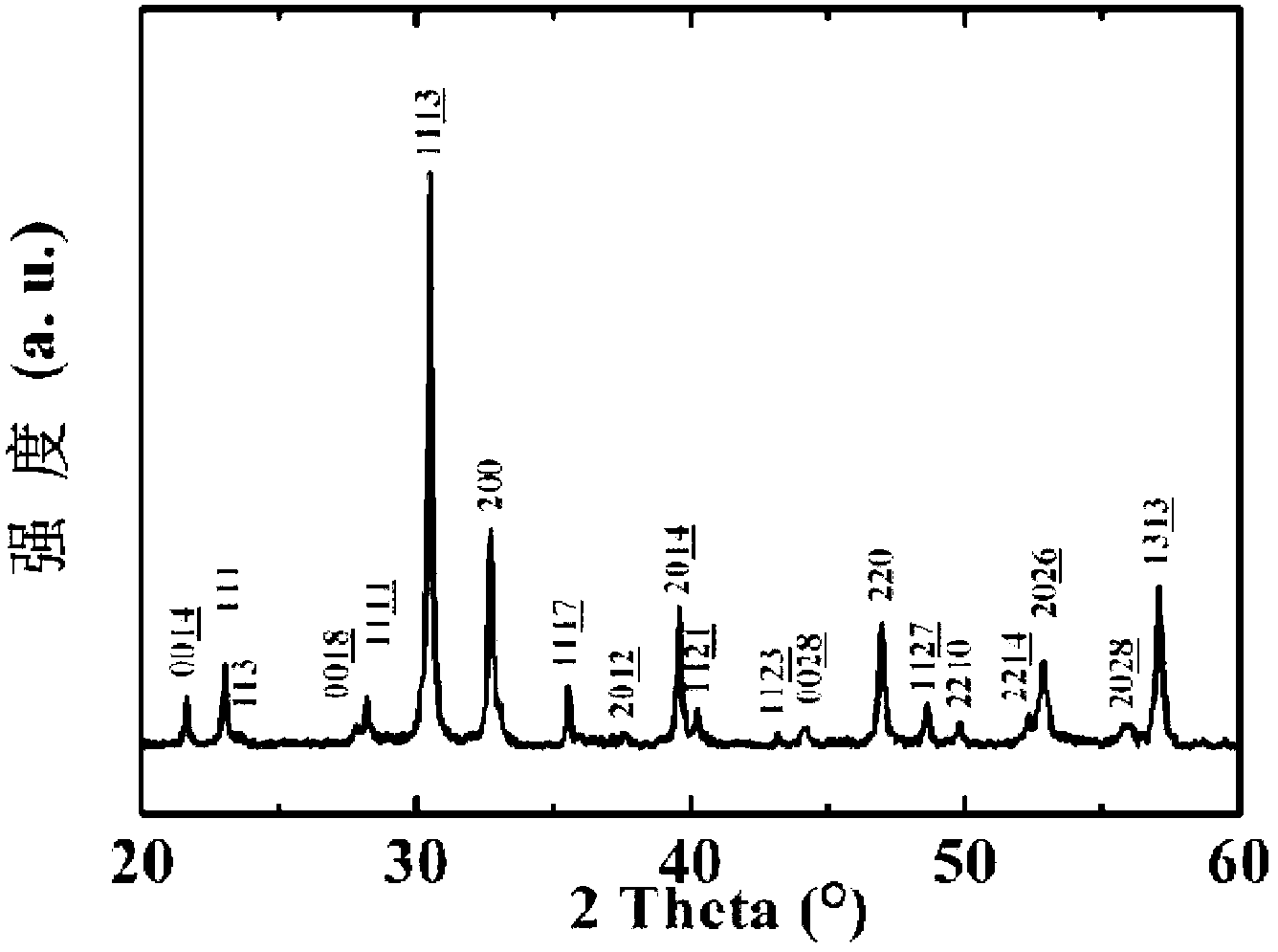

Layered perovskite multiferroic material and preparation method thereof

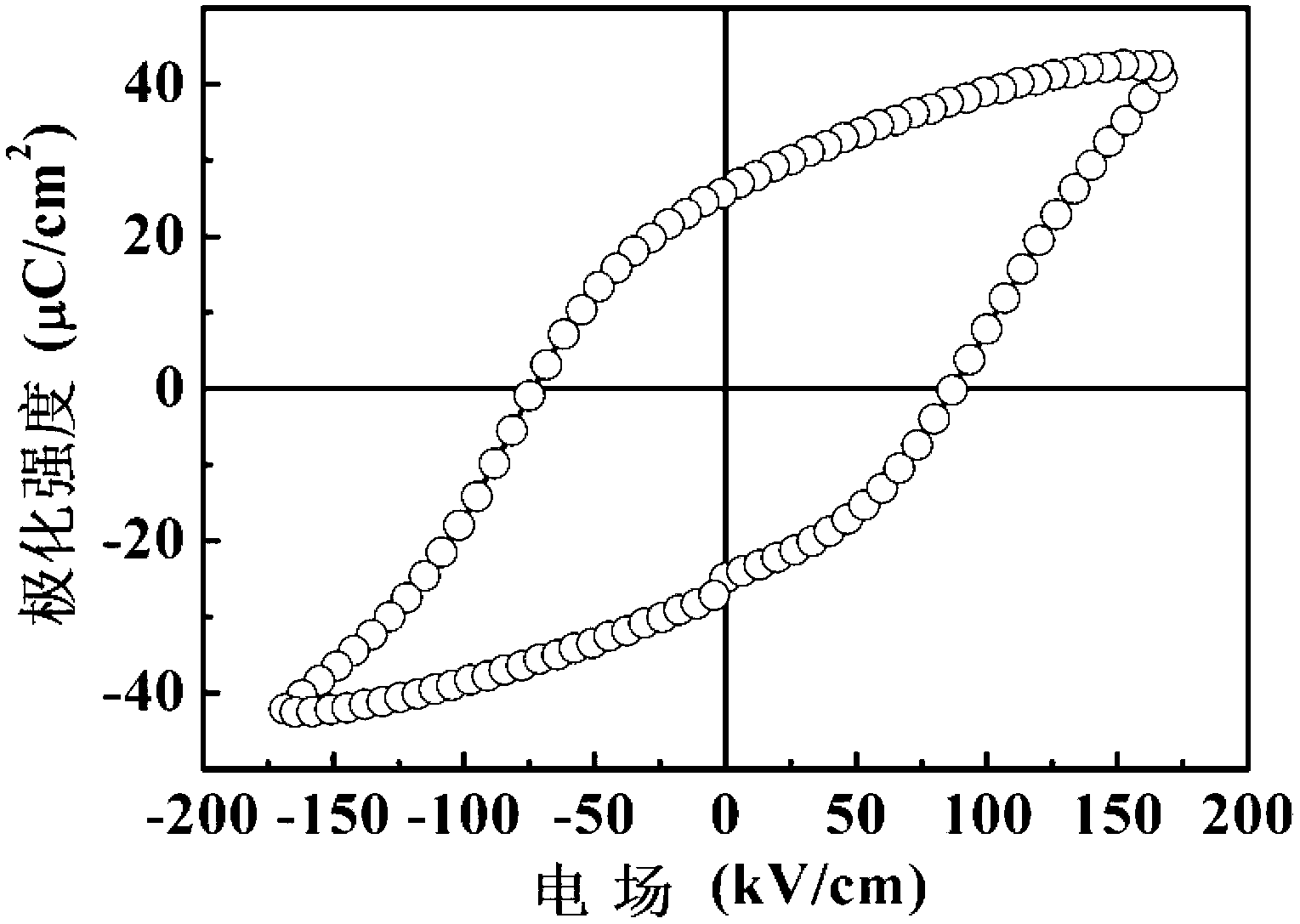

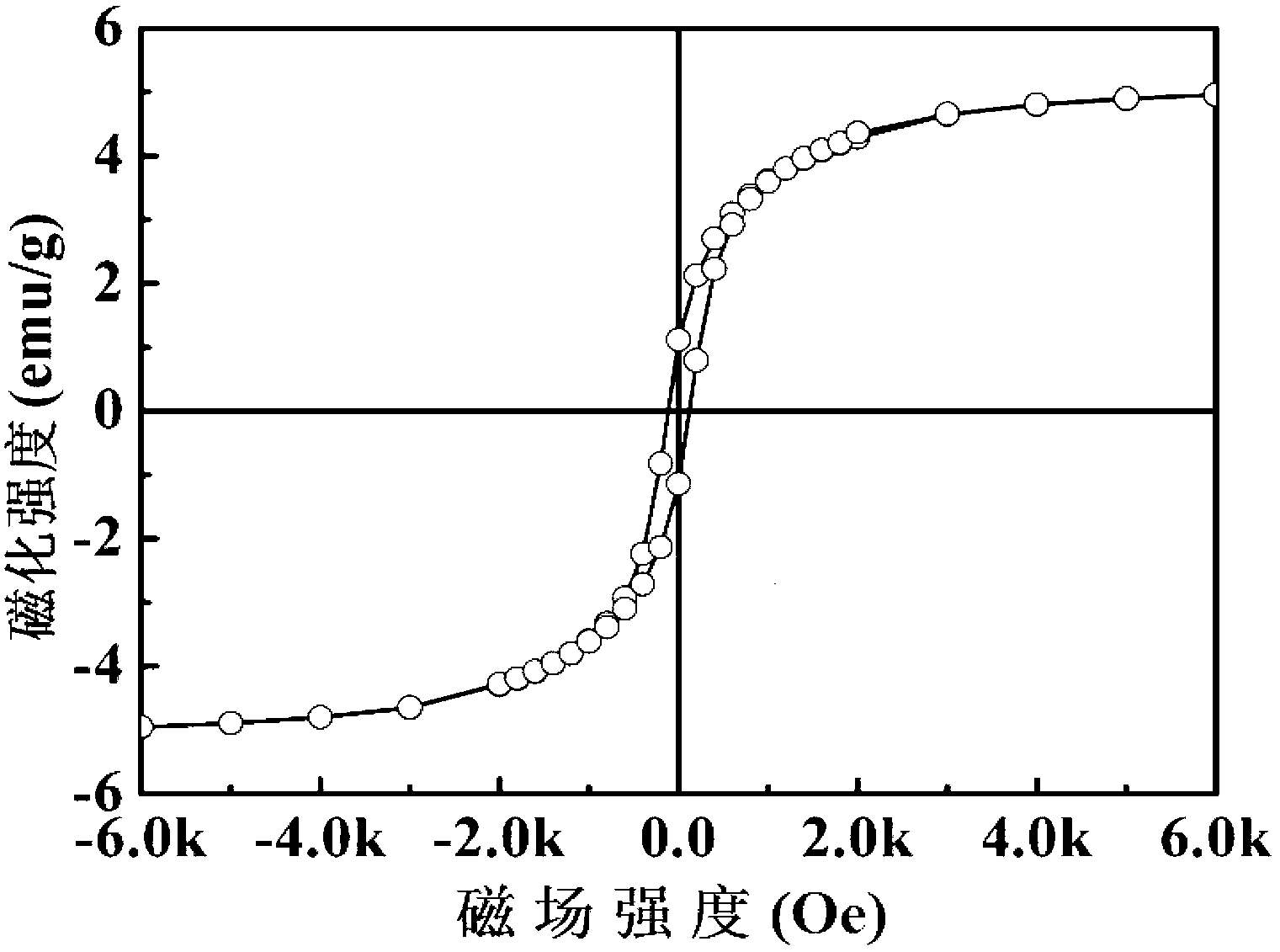

A technology of perovskite structure and multiferroic materials, applied in the field of ceramic materials, can solve the problems of ferroelectric properties, second phase and crystal defects, inferior ferroelectricity of multiferroic materials, etc., so as to improve ferroelectric properties and suppress leakage. phenomenon, the effect of improving ferromagnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a method for preparing a multiferroic material with a layered perovskite structure, comprising:

[0035] The bismuth layered perovskite structure ferroelectric material and the magnetic material containing transition metal elements are mixed by ball milling in deionized water or ethanol, dried, and pre-fired to obtain a layered perovskite structure multiferroic material;

[0036]The bismuth layered perovskite structure ferroelectric material has the molecular formula shown in formula (I):

[0037] (Bi 2 o 2 ) 2+ (A n-1 B n o 3n+1 ) 2- , formula (I);

[0038] Wherein A is selected from any one or more of Na, K, Ca, Sr, Ba, Pb, Bi, La, Y, Gd, Pr, and B is selected from any one or more of Ti, Nb, W, Ta. Several, n is a positive integer.

[0039] The present invention prepares a multiferroic material by inserting a magnetic transition metal element into a bismuth layered perovskite structure ferroelectric material with ferroelectric propertie...

Embodiment 1

[0067] Dissolve 0.4mol of n-butyl titanate, 0.42mol of bismuth nitrate pentahydrate, 0.1mol of strontium nitrate and 20mL of concentrated nitric acid in 200mL of deionized water, then add 0.63mol of ethylenediaminetetraacetic acid and 0.9mol of citric acid, and stir the system evenly Then add ammonia water to adjust its pH value to 7 to obtain a clear solution; place the prepared clear solution in a ceramic evaporating dish for heating and concentration until the solution is evaporated to dryness to obtain a powder; pre-fire the obtained powder in a muffle furnace at 750°C 2h, and then grind to obtain strontium bismuth titanate powder.

[0068] Dissolve 0.21 mol of bismuth nitrate pentahydrate, 0.1 mol of ferric nitrate nonahydrate, 0.1 mol of cobalt nitrate hexahydrate and 10 mL of concentrated nitric acid in 100 mL of deionized water, then add 0.28 mol of ethylenediaminetetraacetic acid and 0.4 mol of citric acid, and stir the system After uniformity, add ammonia water to ad...

Embodiment 2

[0077] Dissolve 0.4mol of n-butyl titanate, 0.42mol of bismuth nitrate pentahydrate, 0.1mol of strontium nitrate and 20mL of concentrated nitric acid in 200mL of deionized water, then add 0.63mol of ethylenediaminetetraacetic acid and 0.9mol of citric acid, and stir the system evenly Then add ammonia water to adjust its pH value to 7 to obtain a clear solution; place the prepared clear solution in a ceramic evaporating dish for heating and concentration until the solution is evaporated to dryness to obtain a powder; pre-fire the obtained powder in a muffle furnace at 750°C 2h, and then grind to obtain strontium bismuth titanate powder.

[0078] Mix 0.1 mol of the prepared strontium bismuth titanate powder with 0.105 mol of bismuth oxide, 0.05 mol of iron oxide and 0.05 mol of cobalt trioxide in deionized water for 30 hours to obtain a wet material; then place the obtained wet material at 80°C After drying, put it in a corundum crucible, and pre-fire it in a muffle furnace at 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com