Method for preparing Sm-Co based magnetic nano-material

A nano-magnetic material, sm-co technology, applied in the direction of nanotechnology, inorganic material magnetism, etc., can solve the problems of easy oxidation of Sm-Co phase, low chemical reduction potential, etc., and achieve environmental friendliness, low production cost, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

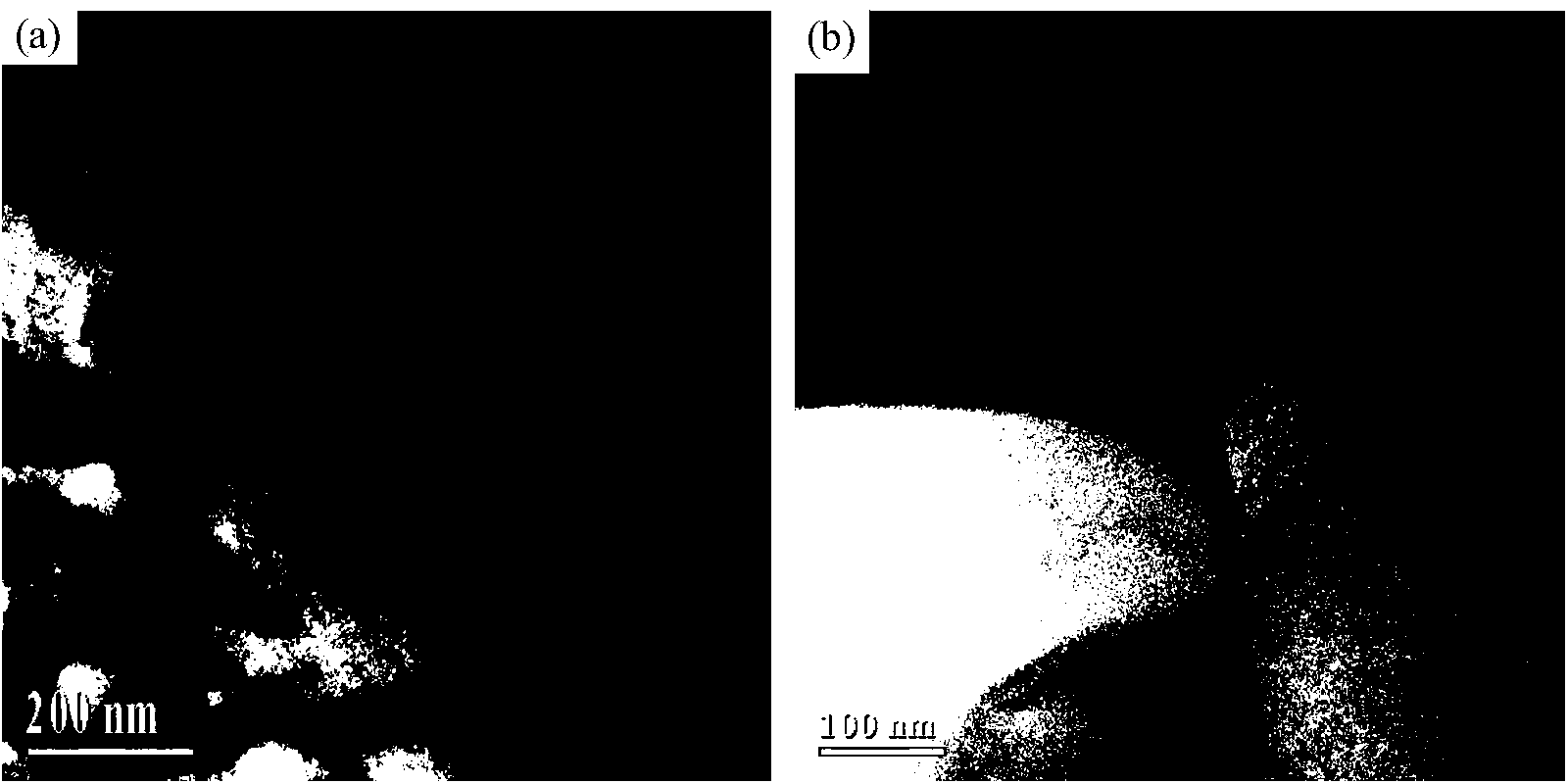

Image

Examples

Embodiment 1

[0037] The first step, raw material preparation

[0038] The elemental composition of the nanomagnetic material prepared according to the requirements is SmCo 6.9 f 0.1 , take the pure Sm, pure Co and pure Hf of raw material proportioning mass by atomic ratio, and add the pure Sm that is 5% of the mass percentage of the above-mentioned pure Sm mass percentage again when actual batching, thus complete the raw material preparation;

[0039] The second step is to melt the raw materials to prepare master alloy ingots

[0040] Put all the raw materials prepared in the first step into the vacuum arc melting furnace for melting. When melting, first vacuumize the furnace body to 10 -2 Pa, the temperature of the furnace is raised above the melting point of the raw metal Co, until all the meltable raw materials are smelted evenly and all the raw materials are uniformly distributed, and then poured into the mold and cooled to room temperature, that is, the SmCo 6.9 f 0.1 master allo...

Embodiment 2

[0055] The first step, raw material preparation

[0056] The elemental composition of the nanomagnetic material prepared according to the requirements is SmCo 6.9 f 0.1 , take the pure Sm, pure Co and pure Hf of the mass ratio of the raw materials in atomic ratio, and add additional pure Sm which is 8% of the mass percentage of the above-mentioned pure Sm mass in the actual batching, thus completing the raw material preparation;

[0057] The second step is to melt the raw materials to prepare master alloy ingots

[0058] Put all the raw materials prepared in the first step into the vacuum arc melting furnace for melting. When melting, first vacuumize the furnace body to 10 -3 Pa, the temperature of the furnace is raised above the melting point of the raw metal Co, until all the meltable raw materials are smelted evenly and all the raw materials are uniformly distributed, and then poured into the mold and cooled to room temperature, that is, the SmCo 6.9 f 0.1 master alloy...

Embodiment 3

[0069] The first step, raw material preparation

[0070] The elemental composition of the nanomagnetic material prepared according to the requirements is SmCo 6.9 f 0.1 , take the pure Sm, pure Co and pure Hf of raw material proportioning mass by atomic ratio, add the pure Sm that is the mass percentage of above-mentioned pure Sm mass percentage 6.5% again when actual batching, complete raw material thus preparation;

[0071] The second step is to melt the raw materials to prepare master alloy ingots

[0072] Put all the raw materials prepared in the first step into the vacuum arc melting furnace for melting. When melting, first vacuumize the furnace body to 10 -2.5 Pa, the temperature of the furnace is raised above the melting point of the raw metal Co, until all the meltable raw materials are smelted evenly and all the raw materials are uniformly distributed, and then poured into the mold and cooled to room temperature, that is, the SmCo 6.9 f 0.1 master alloy ingot;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com