Preparation method of visible-light response type attapulgite-BiOX-TiO2 compound photo-catalyst

An attapulgite and catalyst technology, which is applied in the field of preparation of attapulgite-BiOX-TiO2 composite photocatalyst, can solve the problems of large forbidden band width, low quantum efficiency, easy recombination of photogenerated electrons and holes, and achieves low cost , good coating effect, excellent visible light catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

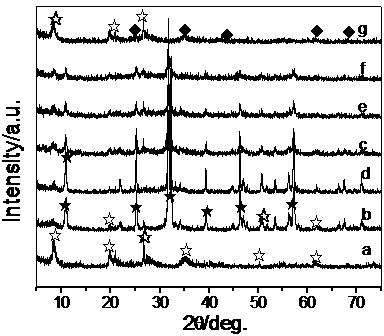

Image

Examples

Embodiment 1

[0019] Embodiment 1: ATT-BiOBr-TiO is synthesized according to the following steps 2 -0.83 composite photocatalyst:

[0020] a) Weigh 5 g of attapulgite and add it to 200 mL of deionized water, stir to promote its dissolution, use the pouring method to remove the sediment settled at the bottom, then sonicate for 1 hour, remove the sediment again, and make attapulgite suspension;

[0021] b) Weigh m(Bi(NO 3 ) 3 ·5H 2 (O)= 4.855g, it was dissolved in 5mL of 2mol L -1 HNO 3 After being completely dissolved, slowly add it dropwise to the attapulgite suspension, stir and mix well, then slowly add 2 mol·L -1 Ammonium bromide aqueous solution 10mL, stir for 30min after adding, then add concentrated ammonia water dropwise to it, adjust pH=6~7, stir for 4h, let stand and age overnight, filter with suction, wash with deionized water 2-3 times, 80 ℃ drying, after grinding, put it into a muffle furnace and bake at 200 ℃ for 2h to get ATT-BiOBr semi-finished product;

[0022] c) Ad...

Embodiment 2

[0035] Embodiment 2: ATT-BiOCl-TiO is synthesized according to the following steps 2 -0.75 composite photocatalyst:

[0036] a) Weigh 5 g of attapulgite and add it to 200 mL of deionized water, stir to promote its dissolution, use the pouring method to remove the sediment settled at the bottom, then sonicate for 1 hour, remove the sediment again, and make attapulgite suspension;

[0037] b) Weigh m(Bi(NO 3 ) 3 ·5H 2 (O)= 4.855g, it was dissolved in 10mL of 2mol L -1 In the HCl aqueous solution, after it is completely dissolved, add it dropwise to the attapulgite suspension, stir for 30 minutes, then add concentrated ammonia water dropwise to it, adjust the pH=6~7, stir for 6 hours, let stand and age overnight, filter with suction, remove Wash with ion water for 2-3 times, dry at 60°C, grind and roast in a muffle furnace at 250°C for 4 hours to obtain ATT-BiOCl semi-finished product;

[0038] c) Add 10.21 g of n-butyl titanate to the ATT-BiOCl semi-finished product in step...

Embodiment 3

[0039] Embodiment 3: ATT-BiOI-TiO is synthesized according to the following steps 2 -0.67 composite photocatalyst:

[0040] a) Weigh 5 g of attapulgite and add it to 200 mL of deionized water, stir to promote its dissolution, use the pouring method to remove the sediment settled at the bottom, then sonicate for 1 hour, remove the sediment again, and make attapulgite suspension;

[0041] b) Weigh m(Bi(NO 3 ) 3 ·5H 2 O)= 4.855g, it is dissolved in 5ml of 2mol L -1 HNO 3 After being completely dissolved, slowly add it dropwise to the attapulgite suspension, stir and mix well, then slowly add 2 mol·L -1 Potassium iodide aqueous solution 10mL, stir for 30min after adding, then add concentrated ammonia water dropwise to it, adjust pH = 6~7, stir for 8h, let stand and age overnight, filter with suction, wash with deionized water 2-3 times, and dry at 60°C , roasted in a muffle furnace at 150°C for 6h after grinding to obtain ATT-BiOI semi-finished products;

[0042] c) Add 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com