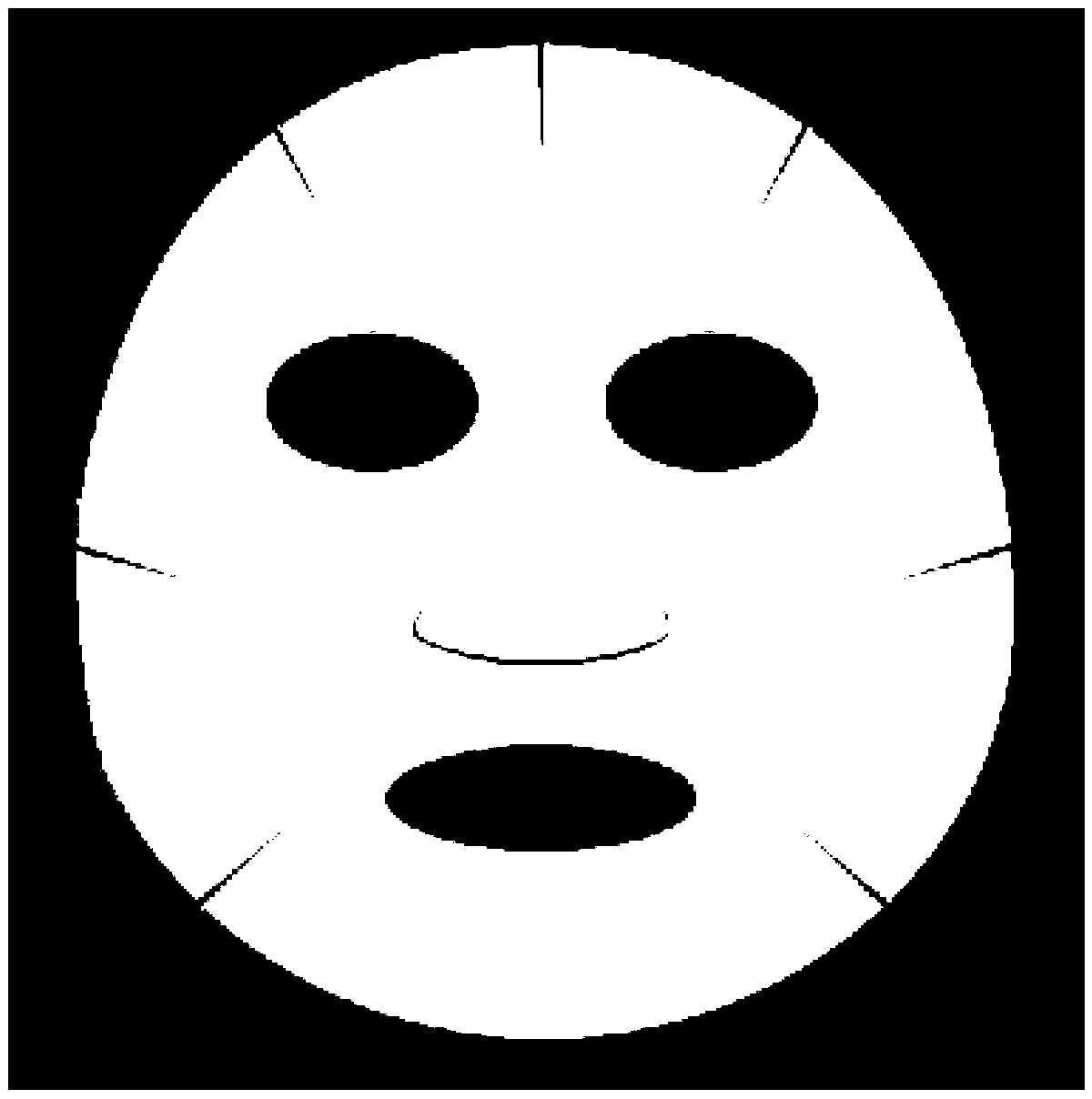

Bacterial cellulose facial mask with gradient structure and preparation method of facial mask

A technology of bacterial cellulose and gradient structure, applied in the direction of microorganism-based methods, biochemical equipment and methods, skin care preparations, etc., can solve the problems of single membrane structure, membrane inhomogeneity, etc., and achieve a wide range of sources and easy portability , product green effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

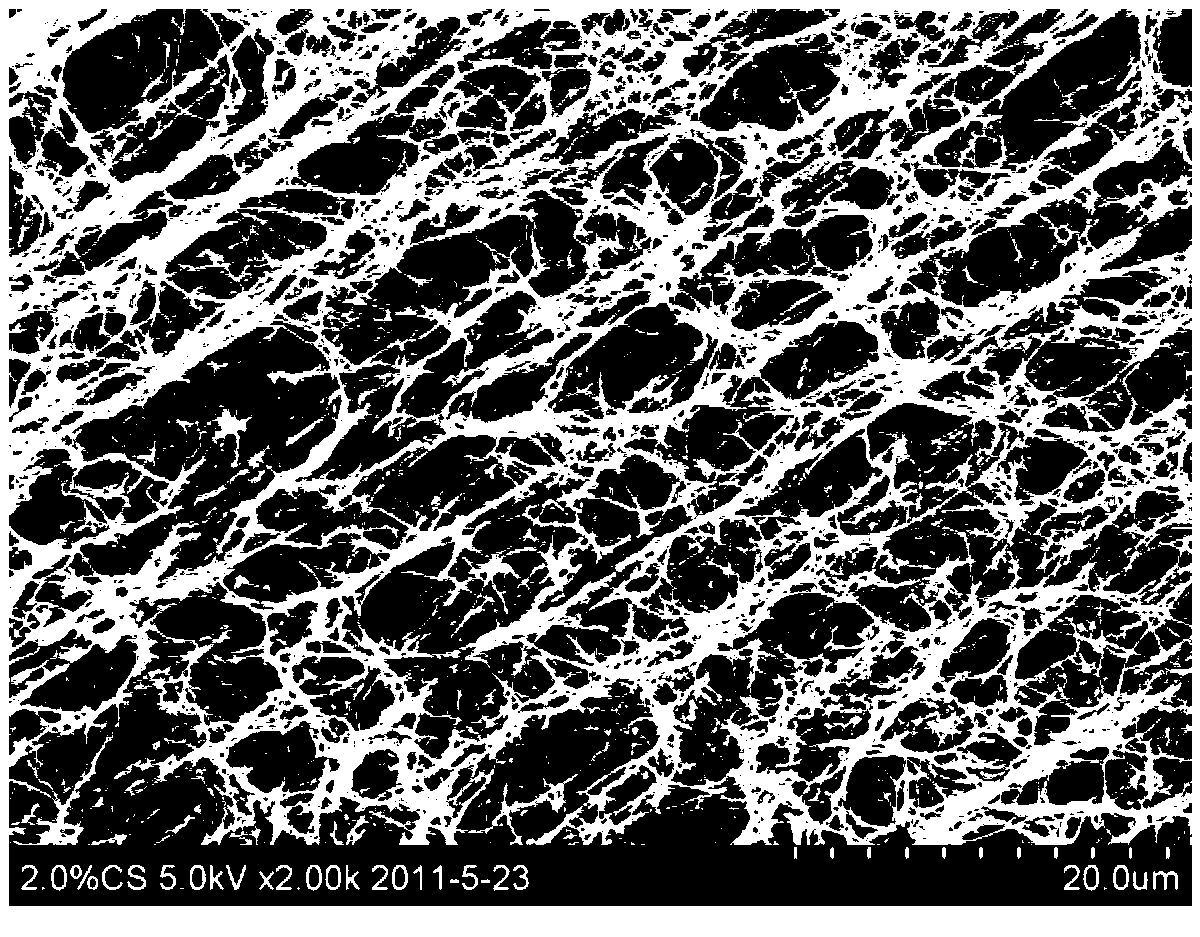

Method used

Image

Examples

Embodiment 1

[0049] 1) the deployment of fermentation broth;

[0050] The components of the culture solution, in mass percent, in wt%: glucose, fructose, sucrose or mannitol 2, peptone 0.05, yeast extract 0.05, citric acid 0.01, disodium hydrogen phosphate 0.02, potassium dihydrogen phosphate 0.01, methyl Cellulose 0.1, wheat starch 0.1;

[0051] The pH of the culture medium is 4.0;

[0052] Heat the culture solution to 50°C to dissolve methyl cellulose and evenly disperse it in the culture solution, at the same time make the wheat starch gelatinize and evenly disperse it in the fermentation culture solution, sterilize by high pressure steam, irradiate with ultraviolet rays and cool to room temperature , through pure oxygen, the fermentation broth is obtained;

[0053] 2) Strain expansion;

[0054] Inoculate and expand the fermentation broth; expansion degree: the number of Acetobacter xylinum cells is 2 × 10 5 pcs / ml.

[0055] 3) static culture;

[0056] Transfer the expanded bacter...

Embodiment 2

[0060] 1) the deployment of fermentation broth;

[0061] The components of the culture solution, in mass percentage, in wt%: glucose, fructose, sucrose or mannitol 3, peptone 0.2, yeast extract 0.2, citric acid 0.05, disodium hydrogen phosphate 0.1, potassium dihydrogen phosphate 0.05, methyl Cellulose 0.5, wheat starch 0.5;

[0062] The pH of the culture medium is 5.0;

[0063] The culture solution was heated to 70°C to dissolve methylcellulose and evenly disperse it in the culture solution, at the same time, the wheat starch was gelatinized and evenly dispersed in the fermentation culture solution, sterilized by high pressure steam, irradiated with ultraviolet rays and cooled to room temperature , through pure oxygen, the fermentation broth is obtained;

[0064] 2) Strain expansion;

[0065] Inoculate and expand the fermentation broth; expansion degree: the number of Acetobacter xylinum cells is 2 × 10 6 pcs / ml.

[0066] 3) static culture;

[0067] Transfer the expande...

Embodiment 3

[0071] 1) the deployment of fermentation broth;

[0072] The components of the culture medium, in mass percent, in wt%: glucose, fructose, sucrose or mannitol 5, peptone 0.5, yeast extract 0.5, citric acid 0.1, disodium hydrogen phosphate 0.2, potassium dihydrogen phosphate 0.1, methyl cellulose 1, wheat starch 1;

[0073] The pH of the culture medium is 6.0;

[0074] The culture solution is heated to 80°C to dissolve and uniformly disperse the thickening agent in the culture solution, meanwhile, the wheat starch is gelatinized and evenly dispersed in the fermentation culture solution, sterilized by high pressure steam, irradiated with ultraviolet rays and cooled to room temperature, Pass through pure oxygen to obtain fermentation broth;

[0075] 2) Strain expansion;

[0076] Inoculate and expand the fermentation broth; expansion degree: the number of Acetobacter xylinum cells is 2 × 10 7 pcs / ml.

[0077] 3) static culture;

[0078] Transfer the expanded bacterial liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com