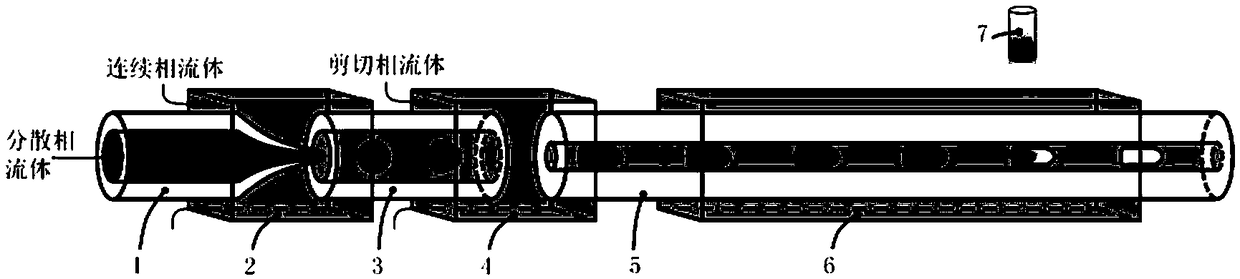

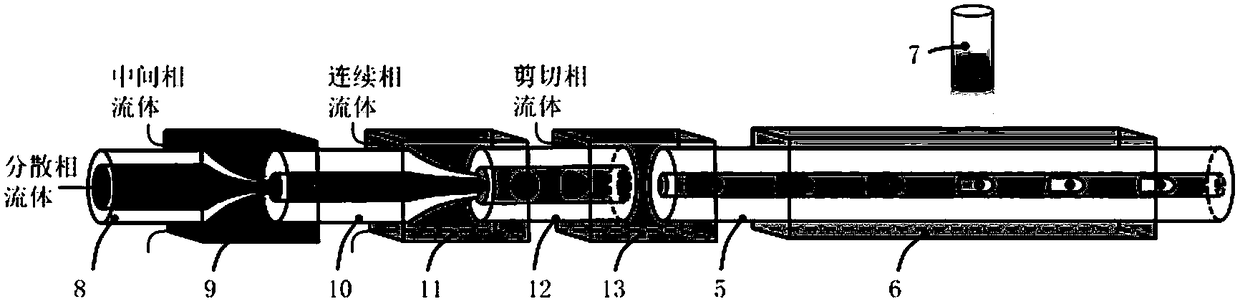

Bullet-shaped non-spherical micro-particle and microcapsule, and preparation method thereof

A non-spherical, micro-particle technology, applied in the direction of microsphere preparation, microcapsule preparation, microcapsules, etc., can solve the problems of inability to achieve continuous preparation, inability to prepare bullet-shaped non-spherical microcapsules, and large shape resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] In this embodiment, bullet-shaped non-spherical microparticles are prepared, and the steps are as follows:

[0078] (1) Preparation of dispersed phase, continuous phase and shear phase fluid

[0079] Prepare the dispersed phase fluid: Dissolve polyethylene glycol diacrylate, 2-hydroxy-2-methyl-1-phenyl-1-propanone and Pluronic F-127 in deionized water at room temperature to obtain the dispersed phase fluid; disperse In the phase fluid, the mass fraction of polyethylene glycol diacrylate is 50%, the mass fraction of 2-hydroxy-2-methyl-1-phenyl-1-propanone is 5%, and the mass fraction of Pluronic F-127 is 1%.

[0080] Preparation of continuous phase fluid: polyglyceryl ricinoleate was dissolved in soybean oil at room temperature to obtain a continuous phase fluid, and the mass fraction of glyceryl ricinoleate in the continuous phase fluid was 4%.

[0081] Preparation of shear phase fluid: polyglyceryl ricinoleate was dissolved in soybean oil at room temperature to obtai...

Embodiment 2

[0090] In this embodiment, bullet-shaped non-spherical microparticles are prepared, and the steps are as follows:

[0091] (1) Preparation of dispersed phase, continuous phase and shear phase fluid

[0092] Prepare the dispersed phase fluid: Dissolve methacryloyloxyethyl carboxyethyl chitosan, 2-hydroxy-2-methyl-1-phenyl-1-propanone and Pluronic F-127 in deionized Obtain dispersed phase fluid in water; In the dispersed phase fluid, the massfraction of methacryloyloxyethyl carboxyethyl chitosan is 30%, 2-hydroxyl-2-methyl-1-phenyl-1-acetone The mass fraction is 20%, and the mass fraction of Pluronic F-127 is 1%.

[0093] Preparation of continuous phase fluid: polyglyceryl ricinoleate was dissolved in soybean oil at room temperature to obtain a continuous phase fluid, and the mass fraction of glyceryl ricinoleate in the continuous phase fluid was 20%.

[0094] Preparation of shear phase fluid: polyglyceryl ricinoleate was dissolved in soybean oil at room temperature to obtain ...

Embodiment 3

[0103] In this embodiment, bullet-shaped non-spherical microparticles are prepared, and the steps are as follows:

[0104] (1) Preparation of dispersed phase, continuous phase and shear phase fluid

[0105] Prepare the dispersed phase fluid: Dissolve polyethylene glycol diacrylate, 2-hydroxy-2-methyl-1-phenyl-1-propanone, and sodium dodecylsulfonate in deionized water at room temperature to obtain the dispersed phase Fluid; in the dispersed phase fluid, the mass fraction of polyethylene glycol diacrylate is 80%, the mass fraction of 2-hydroxy-2-methyl-1-phenyl-1-propanone is 1%, dodecyl sulfonate The mass fraction of sodium bicarbonate is 20%.

[0106] Preparation of continuous phase fluid: Span80 was dissolved in soybean oil at room temperature to obtain a continuous phase fluid, and the mass fraction of Span80 in the continuous phase fluid was 1%.

[0107] Preparation of shear phase fluid: Span20 was dissolved in soybean oil at room temperature to obtain a shear phase flui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com