Conductive hard carbon film, and film forming method therefor

一种硬质碳膜、成膜方法的技术,应用在电路、放电管、电气元件等方向,能够解决品质参差不齐、探头基材耐磨损性不充分、检查结果不稳定等问题,达到稳定体积电阻率和硬度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

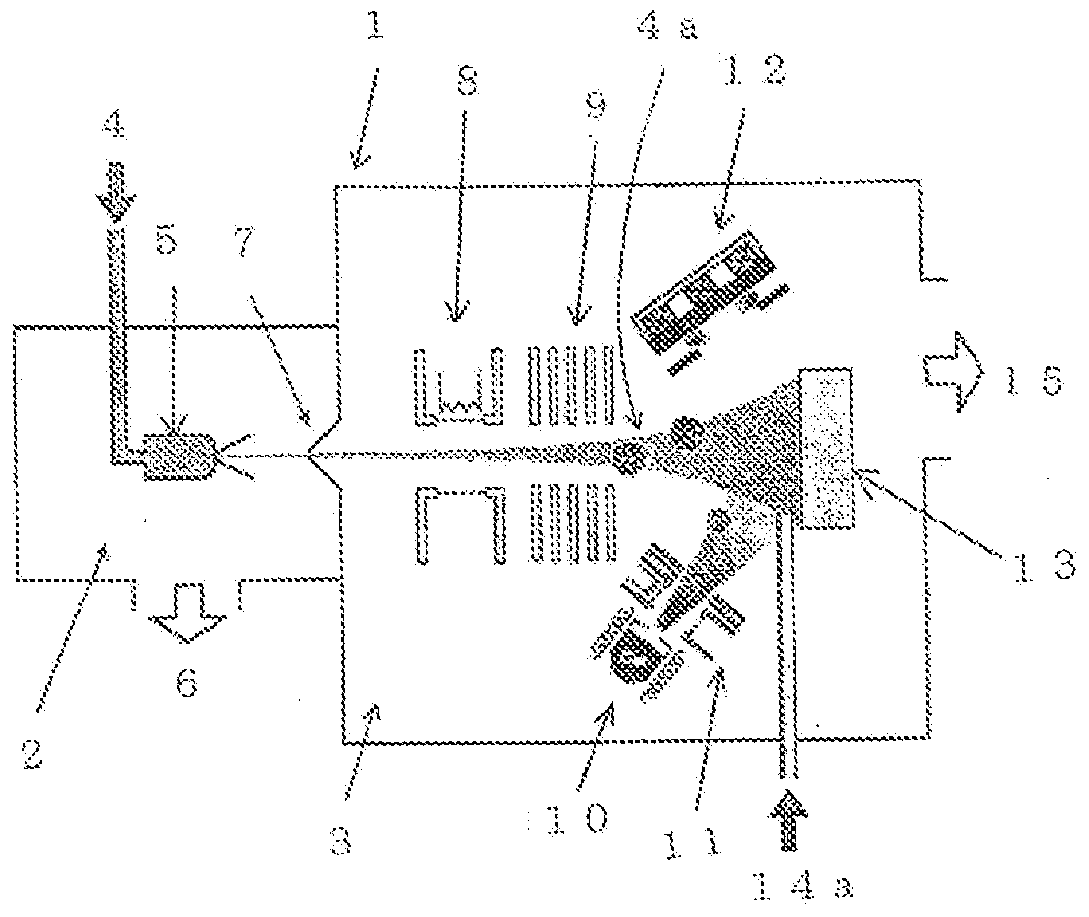

[0100] As the substrate 13 , a square silicon wafer with a size of 50 mm×50 mm was used. Mount the silicon on the figure 1 In the device shown, the 5 x 10 16 piece / cm 2 The surface of the silicon wafer is cleaned by irradiating argon cluster ions with an average number of argon atoms of 1000 accelerated at 20kV under the condition of . The number of argon atoms constituting a cluster is determined by the Time of Flight method. The argon cluster ions themselves are generated from the glass cluster generating nozzle 5 , introduced into the processing section 3 using gas cluster ions through the flow divider 7 , and are ionized by the electron collision method in the ionization section 8 to collide with the surface of the silicon wafer 13 .

[0101] After the surface of the silicon wafer is cleaned, the evaporated particles as carbonaceous materials are heated in the crucible to evaporate fullerene, and at the same time, the evaporated particles as boron materials pass through...

Embodiment 2

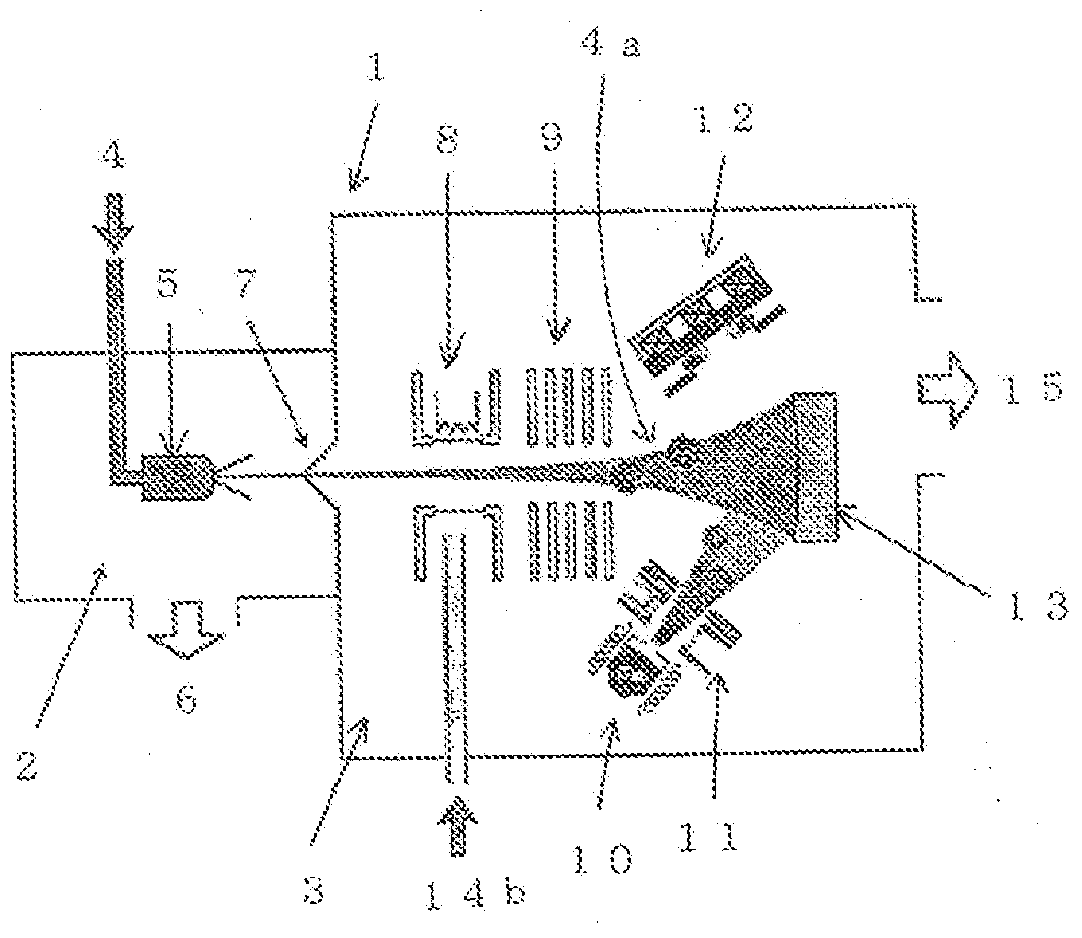

[0103] In addition to using figure 2 Except for the apparatus shown, a sample in which a boron-containing carbon film substantially free of hydrogen was formed was prepared in the same manner as in Example 1 (evaporating particles of diborane were used as the evaporating particles of boron material).

Embodiment 3

[0105] In addition to using figure 2 In the shown device, a sample having a boron-containing carbon film substantially free of hydrogen was produced in the same manner as in Example 1, except that trimethylboron was used as the boron material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com