High thermal conductivity silicon carbide grouting material combined with sol used for bottom leveling of blast furnace

A technology of silicon carbide and high thermal conductivity, applied in the field of refractory materials, can solve the problems of low thermal conductivity of graphite raw materials, easy to be eroded, and reduce thermal conductivity, etc., to achieve stable material volume, simple and easy to operate process, and reduce erosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

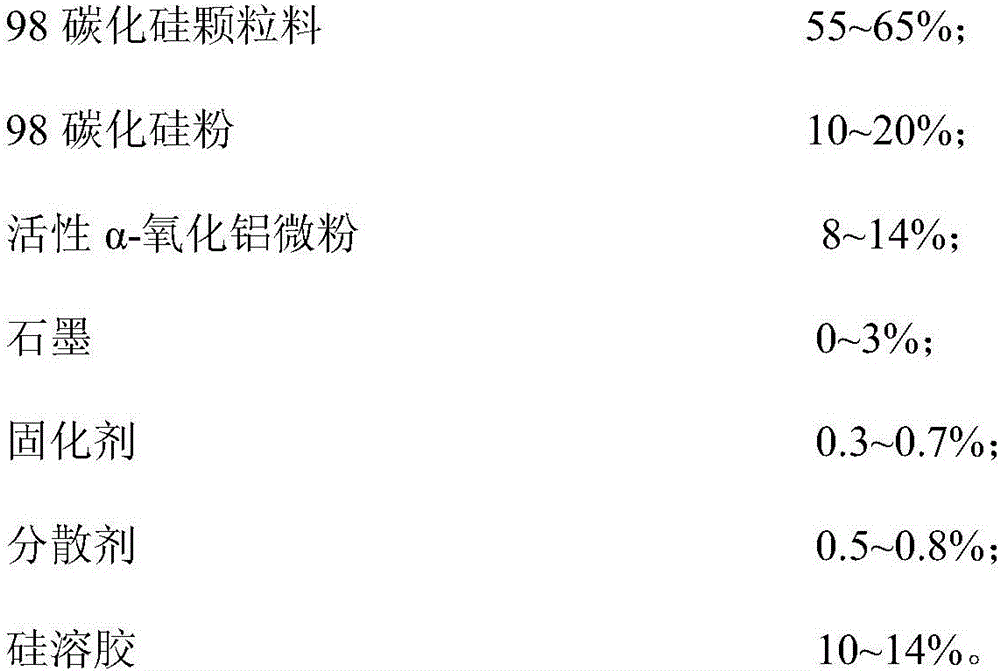

Method used

Image

Examples

Embodiment 1

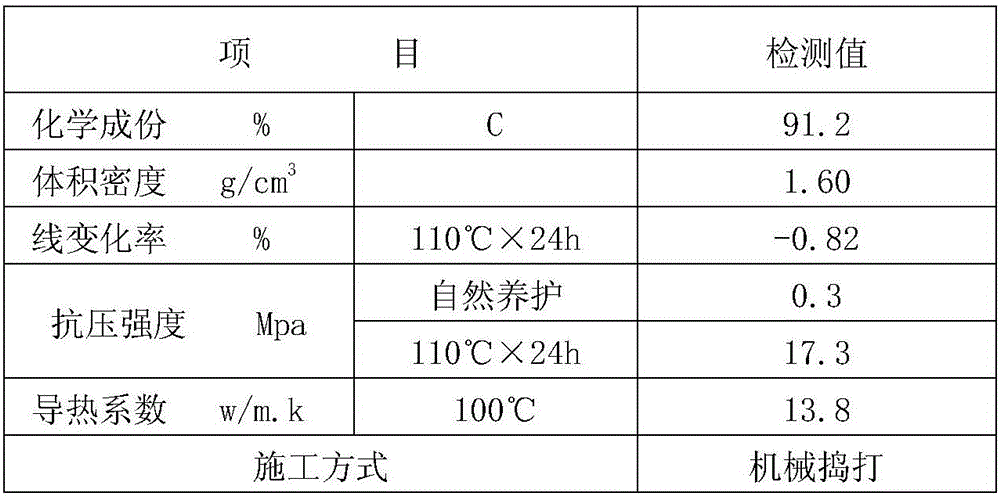

[0050] The temperature of the 4# blast furnace bottom of a D steel plant in China increased a lot. It was found that it was caused by the leakage of high-temperature and high-pressure gas at the bottom of the furnace. During the dismantling of refractory materials in the furnace, it was found that carbon ramming material was used on both the sealing plate and the lower part. It was clearly visible on the site that the ramming material had shrunk severely, and large shrinkage cracks had occurred in many places, and it had been separated from the scale plate. According to expert analysis, it is due to the low thermal conductivity of the refractory material at the bottom of the furnace that the heat cannot be transmitted to the cooling system in time, which accelerates the erosion of the furnace lining. During the use of furnace bottom ramming materials, large shrinkage cracks are formed to form gas leakage channels. Under the erosion and erosion of high-temperature and high-press...

Embodiment 2

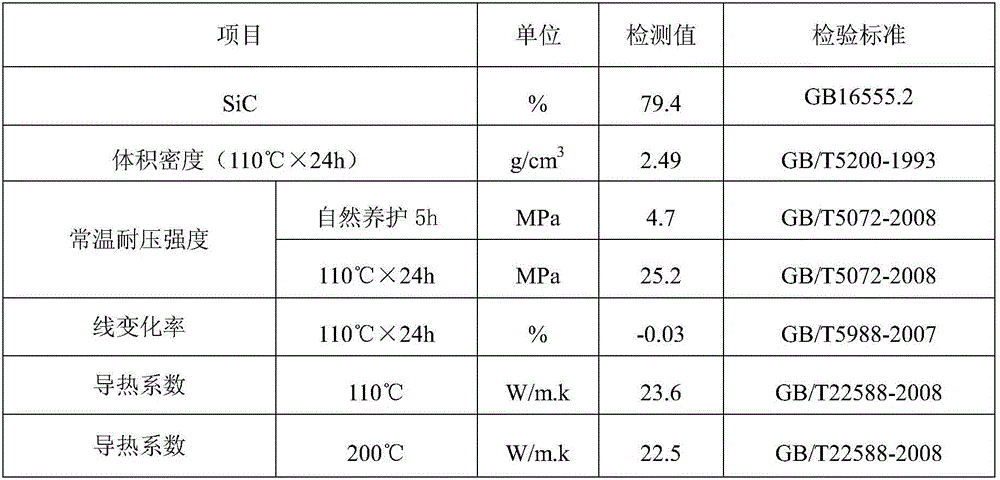

[0073] A domestic E steel plant 2580m 3 In the 11# and 4# blast furnace overhaul and renovation projects, the bottom leveling layer parts are also supplied and constructed by our company, and the construction period is only 36 hours. The standardization of the construction process is the same as that of Example 1. Its ingredient composition is shown in Table 4.

[0074] Table 4E plant sol combined with high thermal conductivity silicon carbide potting material ratio (weight percent)

[0075] project weight percentage 98 silicon carbide pellets (0.074~5mm) 61% 98 silicon carbide powder (0.045~0.074mm) 13% Active α-Al 2 o 3 Micropowder

12% Graphite (1mm~0.074mm) 2% Curing agent (≤0.074mm) 0.5% Dispersant 0.6% Silica sol (solid content 40%) 10.9%

[0076] The 98 silicon carbide granules meet the following requirements: SiC≥98wt%, select silicon carbide with better crystallinity of single crystal structure; the parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com