Electric field induction rheology forming method of paraboloid-like microlens array

An electric field-induced rheology and micro-lens array technology, applied in lenses, optics, instruments, etc., can solve the problems of large optical surface roughness, affecting adoption and promotion, etc., and achieve the effect of reducing processing costs and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] An electric field-induced rheological deformation method of a parabolic microlens array, comprising the following steps:

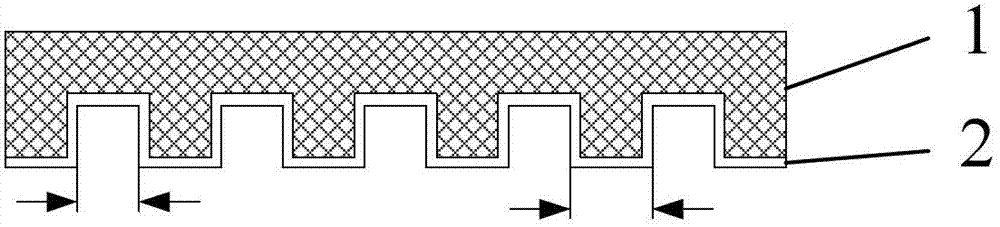

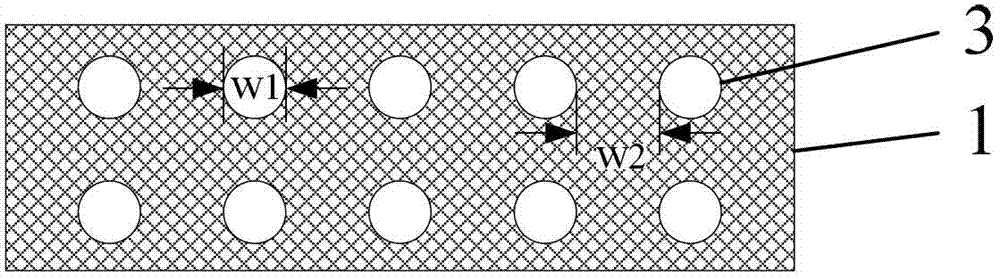

[0022] 1) Preparation and processing of the upper plate mold: Referring to Figure 1, the upper plate mold 1 adopts the traditional process of photolithography and etching to make the microhole array 3 on the wafer, and then thermally heats it on the surface of the patterned wafer. Oxidize the SiO2 dielectric layer 2 with a thickness of 1um. After completion, use the surface treatment agent F1060 to treat the surface of the wafer with low surface energy to prevent damage to the lens array structure during demoulding;

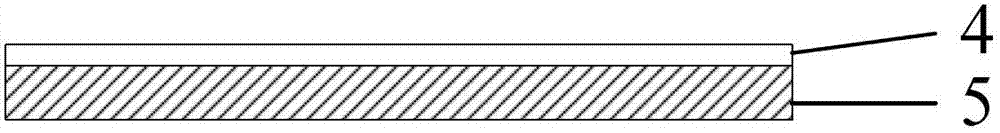

[0023] 2) Selection of lower plate and polymer: prepare transparent conductive ITO glass as the lower plate, and its preparation method is as follows: refer to figure 2 , using PECVD technology to vapor-deposit a layer of 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com