Preparation method of macromolecule plasticizer based on recycled cooking oil

A technology of macromolecular plasticizer and waste oil, which is applied in the field of preparation and modification of functional polymer materials, can solve toxic and harmful problems, achieve long-lasting and stable plasticizing performance, significant economic benefits, and avoid the effect of flowing to the dining table again

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

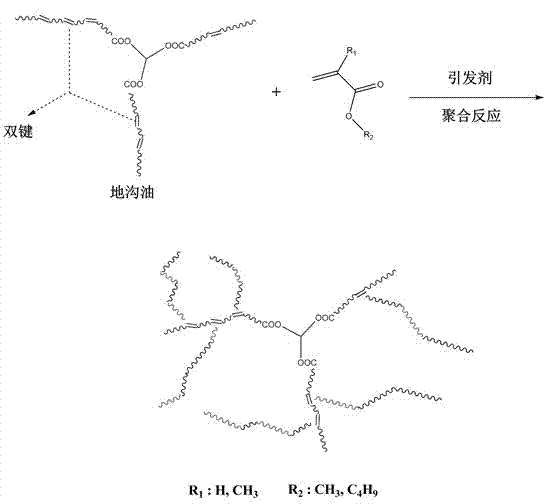

[0030] A kind of preparation method of the macromolecule plasticizer based on waste oil, wherein, comprises the following steps:

[0031] Step 1, washing, decolorizing, filtering, absorbing, and sterilizing the waste oil to obtain purified waste oil whose main chemical composition is unsaturated fatty acid glyceride;

[0032] Step 2, the purified waste oil obtained in step 1 and high polymerization activity monomer, glass transition temperature regulating monomer and PVC similar solubility parameter monomer are mass ratio 5~100: 5~20: 0~100: 0~50 Mix to obtain a mixed solution, add an initiator with a mass ratio of 0% to 15% to the mixed solution, react at a temperature of 0°C to 150°C, and undergo conventional free radical or living free radical polymerization for 1 hour After 10 hours, a macromolecular plasticizer based on waste oil was obtained.

[0033] In an embodiment, the initiator is azobisisobutyronitrile, azobisisoheptanonitrile, dibenzoyl peroxide, dicumyl peroxide...

Embodiment 1

[0046] Add 100 g of ethyl acetate, 100 g of purified waste oil, 10 g of styrene, 50 g of butyl acrylate, 25 g of methyl methacrylate and 10 g of diphenyl peroxide into a three-necked flask with a heating and stirring device. Formyl, after mixing evenly, gradually increase the system temperature to 70°C, after 7 hours of heat preservation reaction, raise the system temperature to 78°C, continue the heat preservation reaction for 2 hours, then cool the system temperature to 40°C, to obtain waste oil based A solution-polymerizable macromolecular plasticizer.

Embodiment 2

[0048] Add 80 g absolute ethanol, 20 g purified water, 100 g purified waste oil, 25 g styrene, 100 g n-octyl acrylate, 50 g methyl acrylate and 20 g Ammonium persulfate, after mixing evenly, gradually raise the system temperature to 75°C, after 8 hours of heat preservation reaction, raise the system temperature to 80°C, continue the heat preservation reaction for 2 hours, then cool the system temperature to 40°C, that is, the trench-based Precipitation polymerization macromolecule plasticizer of oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com