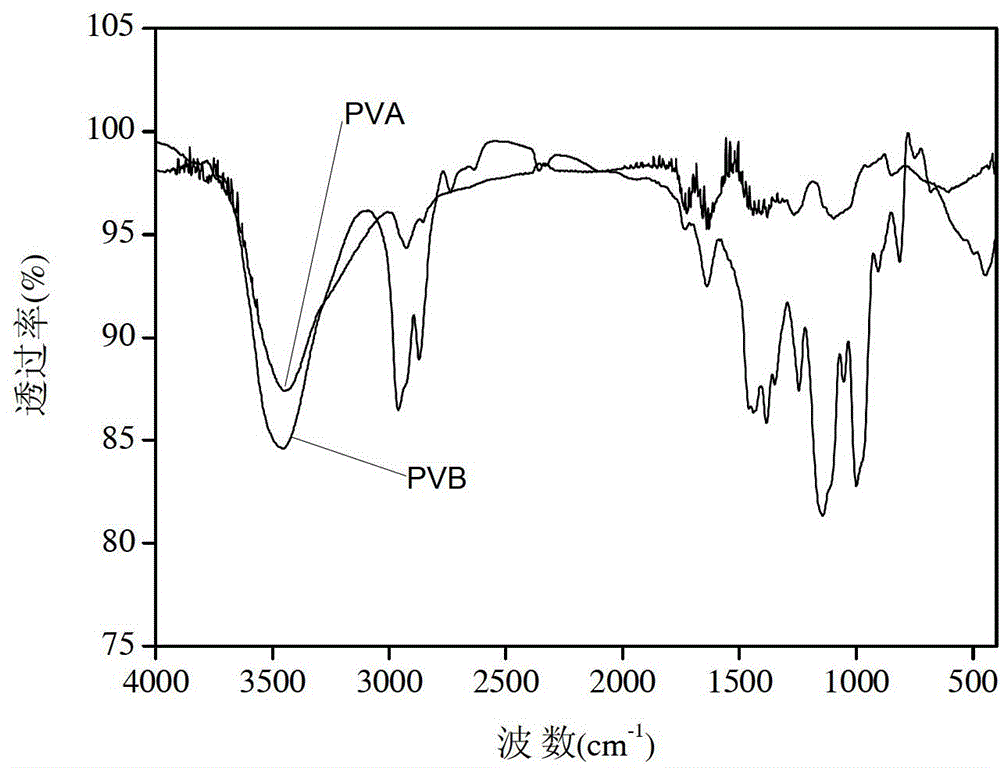

Low-viscosity polyvinyl butyral resin as well as preparation method and application thereof

A technology of polyvinyl butyral resin and polyvinyl alcohol, which is applied to the preparation of low-viscosity polyvinyl butyral PVB resin, preparation, and the field of polyvinyl butyral PVB resin, can solve the problem of low production efficiency and easy Discoloration, low degree of acetalization and other problems, to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A low-viscosity polyvinyl butyral PVB resin is prepared from polyvinyl alcohol PVA, n-butyraldehyde, degradation agent, pH regulator, antioxidant, emulsifier and acid catalyst through acetal reaction.

[0061] The concentration of the PVA aqueous solution is 8%.

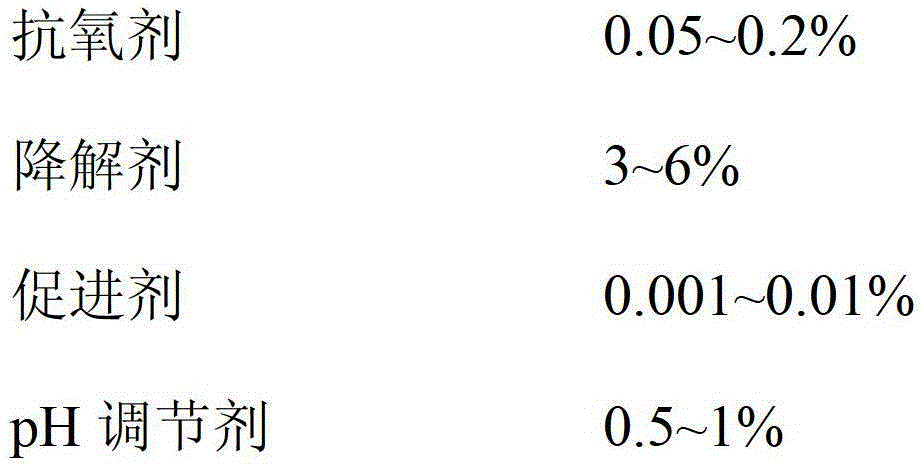

[0062] The raw materials used in the method consist of:

[0063]

[0064] The rest is polyvinyl alcohol.

[0065] The method for preparing low-viscosity polyvinyl butyral resin may further comprise the steps:

[0066] (1) Fully dissolve 15kg of PVA in deionized water at 90-98°C to obtain a PVA aqueous solution with a concentration of 8%;

[0067] (2) Add 0.13kg of sodium hydroxide to the solution obtained in step (1), adjust the pH value of the solution at 9-11, then add 0.80kg of sodium hypochlorite and 0.0027kg of accelerator to fully degrade PVA;

[0068] (3) After adjusting the temperature of the solution obtained in step (2) to 30-40°C, add 0.027kg of sodium lauryl sulfate;

[0069] (4) After adjus...

Embodiment 2

[0073] A low-viscosity polyvinyl butyral PVB resin is prepared from polyvinyl alcohol PVA, n-butyraldehyde, degradation agent, pH regulator, antioxidant, emulsifier and acid catalyst through acetal reaction.

[0074] The concentration of the PVA aqueous solution is 10%.

[0075] The raw materials used in the method consist of:

[0076]

[0077] The rest is polyvinyl alcohol.

[0078] The method for preparing low-viscosity polyvinyl butyral resin may further comprise the steps:

[0079] (1) Fully dissolve 15kg of PVA in deionized water at 90-98°C to obtain a 10% PVA aqueous solution;

[0080] (2) Add 0.18kg sodium hydroxide to the solution obtained in step (1), adjust the pH value of the solution at 9-11, then add 1.19kg sodium hypochlorite and 0.0027kg accelerator to fully degrade PVA;

[0081] (3) After adjusting the temperature of the solution obtained in step (2) to 30-40°C, add 0.0299kg of sodium dodecyl sulfate;

[0082] (4) After adjusting the temperature of the s...

Embodiment 3

[0086] A low-viscosity polyvinyl butyral PVB resin is prepared from polyvinyl alcohol PVA, n-butyraldehyde, degradation agent, pH regulator, antioxidant, emulsifier and acid catalyst through acetal reaction.

[0087] The concentration of the PVA aqueous solution is 10%.

[0088] The raw materials used in the method consist of:

[0089]

[0090] The rest is polyvinyl alcohol.

[0091] The method for preparing low-viscosity polyvinyl butyral resin may further comprise the steps:

[0092] (1) Fully dissolve 15kg of PVA in deionized water at 90-98°C to obtain a 10% PVA aqueous solution;

[0093] (2) Add 0.21 kg of potassium hydroxide to the solution obtained in step (1), adjust the pH value of the solution in the range of 9 to 11, then add 1.39 kg of hydrogen peroxide and 0.0027 kg of accelerator to fully degrade PVA;

[0094] (3) After adjusting the temperature of the solution obtained in step (2) to 30-40°C, add 0.035kg of sodium dodecylbenzenesulfonate;

[0095] (4) Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com