A kind of method for electrolytic preparation of high-purity zinc

A high-purity, zinc-grain technology, applied in the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of calcium and magnesium enrichment, serious ammonia volatilization, complicated operation, etc., to avoid the purification process of zinc powder, storage And the effect of convenient transportation, simple and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

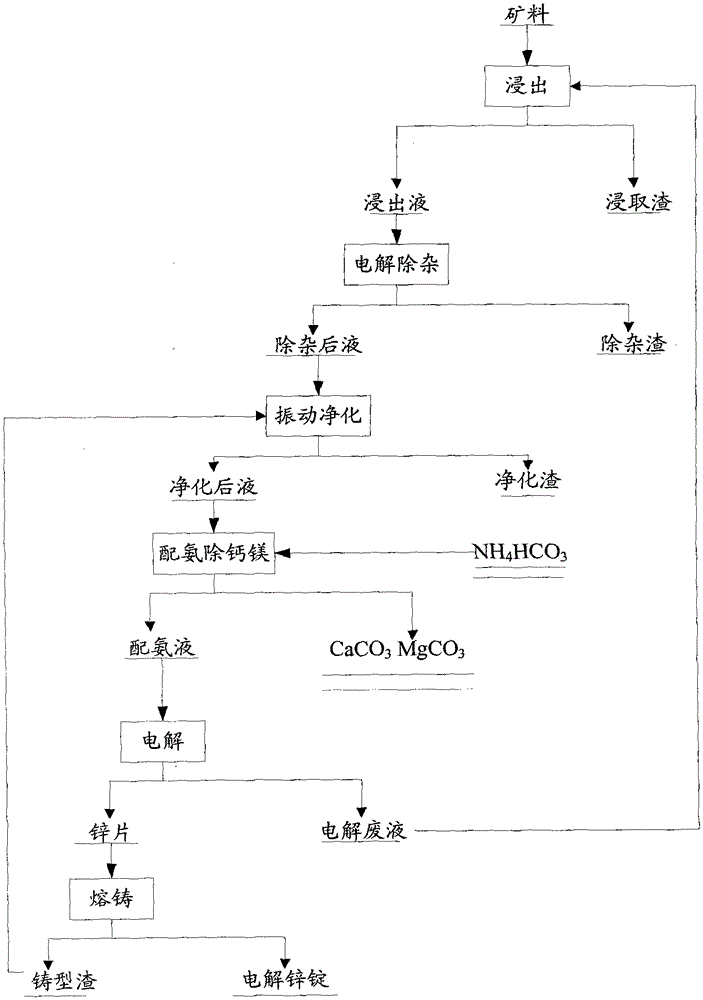

Method used

Image

Examples

Embodiment 1

[0060] 1. Leach a zinc-containing material with ammonium chloride solution, the specific content is Zn31.3%, Pb3.89%, Cd1.75%, Cu0.07%, Cl6%, Fe9%, As1.25%, Sb0 .34%; temperature 80°C, time 90min, zinc ammonia complex solution was obtained, after testing: Zn68.54g / L, Pb3.92g / L, Cu0.06g / L, Cd1.58g / L, Cl5.6M / L, Fe0.0046g / L, As0.003g / L, Sb0.005g / L;

[0061] 2. Take the above-mentioned 10 cubic meters of zinc ammonia complex solution for preliminary electrolysis to remove impurities. The electrolysis conditions are: the anode is a graphite plate with a total area of 50m 2 , the cathode is also a graphite plate with a total area of 100m 2 , the distance between different poles is 40 mm; constant voltage 2.1V electrolysis, temperature 75 degrees, after 120 minutes of electrolysis time, the cathode current density drops to 130A / m 2 , the electrolysis of impurity is over, the measured power consumption is 124 degrees, the solution after electrolysis is filtered and tested, and ...

Embodiment 2

[0071] 1. Leach a zinc-containing material Zn36.64%, Pb0.83%, Cu2.2%, and Cd4.19% with ammonium chloride solution; the temperature is 80 degrees, and the time is 90 minutes to obtain a zinc-ammonia complex solution After testing: Zn68.7g / L, Pb1.06g / L, Cu2.66g / L, Cd4.31g / L, Cl5.6M / L, Fe0.003g / L, As0.0003g / L, Sb0.0005g / L;

[0072] 2. Take the above-mentioned 10 cubic meters of zinc ammonia complex solution for preliminary electrolysis to remove impurities. The electrolysis conditions are: the anode is a graphite plate with a total area of 50m 2 , the cathode is also a graphite plate with a total area of 100m 2 , the distance between different poles is 40 mm; constant voltage 2.2V electrolysis, temperature 75 degrees, after 180 minutes of electrolysis time, the cathode current density drops to 75A / m 2 , the electrolysis is over, the measured power consumption is 254 degrees, the solution after electrolysis is filtered and tested, and the contents of each element are: Zn67....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com