Electrochemical method for improving photoelectric performance of nano bismuth vanadate film

A nano-bismuth vanadate, photoelectric performance technology, applied in chemical instruments and methods, solid-state chemical plating, circuits, etc., can solve the problems of low photocatalytic pollutant efficiency, achieve strong controllability, simple equipment, and improve photoelectricity. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) First, ultrasonically clean the ITO conductive glass with ammonia water and 30% hydrogen peroxide at a volume ratio of 1:1, and then ultrasonically clean with acetone, absolute ethanol and deionized water in sequence;

[0018] 2) Bi(NO at a concentration of 0.2 M 3 ) 3 .5H 2 O-acetic acid solution and vanadyl acetylacetonate-acetylacetone solution with a concentration of 0.03 M are uniformly mixed according to the molar ratio of Bi:V 1:1 to obtain bismuth vanadate colloid;

[0019] 3) Spin-coat bismuth vanadate colloid on the ITO conductive glass on a KW-4A desktop glue homogenizer, then put the colloid-coated ITO conductive glass into a muffle furnace, bake at 500°C for 10 min, and repeat the above method Spin-coating and baking 6 times, the last baking at 500°C for 0.5 h, and natural cooling to obtain nano-bismuth vanadate film;

[0020] 4) Sodium perchlorate is fully dissolved in deionized water, and a sodium perchlorate aqueous solution with a concentration of...

Embodiment 2

[0026] The method is the same as that of Example 1, except that step 5) applies a voltage of -0.3V, and the electrochemical surface treatment time is 5 minutes.

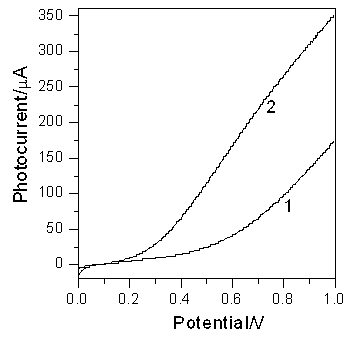

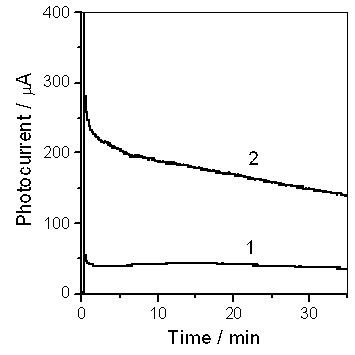

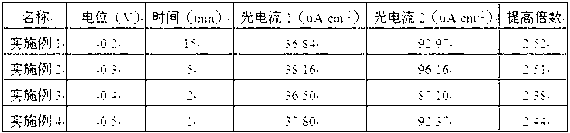

[0027] The photoelectric performance test results are shown in Table 1: Under the condition of an applied bias voltage of 0.6 V, the photocurrent increased by 2.51 times after electrochemical surface treatment.

Embodiment 3

[0029] The method is the same as Example 1, except that the electrolyte concentration is 0.1 M sodium perchlorate aqueous solution, step 5) a voltage of -0.4V is applied, and the electrochemical surface treatment time is 2 minutes.

[0030] The photoelectric performance test results are shown in Table 1: Under the condition of an applied bias voltage of 0.6 V, the photocurrent increased by 2.38 times after electrochemical surface treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com