Short bacillus and method for preparing trehalose by virtue of fermentation

A technology of trehalose and short, which is applied in Brevibacterium and its application in the fermentation and preparation of trehalose, in the field of microbial fermentation, can solve the problems of complex preparation process, high cost, and difficult separation, so as to achieve simple preparation process and increase yield , the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

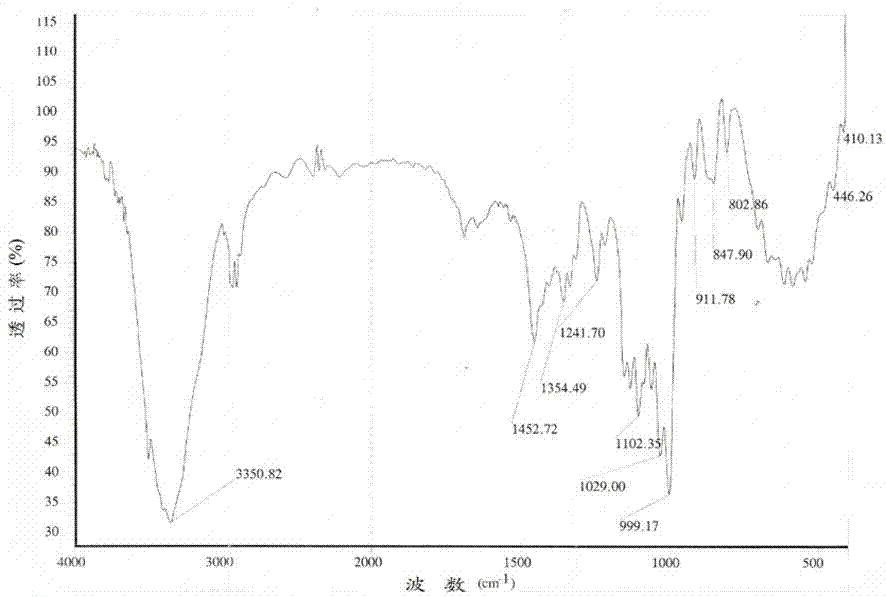

Image

Examples

Embodiment 1

[0042] Example 1 Mutagenesis Treatment Screening of Brevibacterium Mutants and Performance Testing

[0043] The strain was originally isolated from the soil, and it is a high-yielding strain of trehalose obtained through primary screening, re-screening and ultraviolet mutagenesis. Curtobacterium sp. SY311, with the preservation number CGMCC No.7181, was preserved in the General Microbiology Center of the China Microbiological Culture Collection Management Committee, and the preservation date was January 21, 2013. It specifically includes the following steps:

[0044] 1) Primary screening

[0045] From the candidate strains, select the strain that can decompose trehalose, that is, produce trehalase. The specific method is to plant the various strains preserved on the slant on the screening plate with trehalose as the only carbon source (the composition of the medium (mass volume ratio): 2% trehalose; 0.5% (NH 4 ) 2 SO 4 ;0.05% yeast extract; 0.1%KH 2 PO 4 ;0.06%Na 2 HPO...

Embodiment 2

[0051] Example 2 Preparation of Trehalose by Shake Flask Fermentation

[0052] The high-yield trehalose strains screened by the present invention can be prepared by optimizing the fermentation process to obtain high-yield trehalose, which specifically includes the following steps:

[0053] The Brevibacterium with the preservation number CGMCC No.7181 Curtobacterium sp. SY311 was transferred to the slant, 30°C, cultured for 48 hours, took 1 ring, inoculated in a 300ml Erlenmeyer flask with 30ml seed medium, 30°C, 200rpm, shaken and cultured for 20h, as the seed liquid; then, the seed liquid was pressed 2- 4% seed quantity is inserted in the 500ml Erlenmeyer flask that 50ml fermented liquid is housed.

[0054] According to the mass volume ratio, the composition of the slant medium: 1% peptone, 0.5% yeast extract, 0.5% wort juice, 0.5% casein, 0.2% beef extract, 0.2% glycerol, 0.005% Toween80, 0.1% MgSO 4 ·7H 2 O, 1.5% agar, the rest is water; pH is 7.0-7.2.

[0055] Accordi...

Embodiment 3

[0061] The Brevibacterium CGMCC No.7181 prepared in Example 1 was transferred to the slant, 30 ° C, cultured for 48 hours, took 1 ring, inoculated in a 300 ml Erlenmeyer flask with 30 ml of seed medium, 30 ° C, 200 rpm, shaking culture for 24 hours, as Seed liquid; then, the seed liquid was inserted into a 2-liter bench-top fermenter equipped with 1.2 liters of fermentation liquid by 3% seed amount and fermented for 72 hours.

[0062] Put 1370ml of the fermentation supernatant (containing 13.8g of trehalose) in a boiling water bath for 10 minutes, and filter to remove the coagulated protein. The clear night flows into the 732 cation exchange column (H + Type, 25×265mm), eluted with deionized water, collected trehalose fraction, flowed into 717 anion exchange column (OH - type, 39×370mm), eluted with deionized water, collected the trehalose fraction, then added 2% activated carbon to decolorize while stirring, and microfiltered the filter membrane (pore size: 0.45 μm) to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com