A kind of active powder concrete mixed with super active slag powder and its preparation method

A technology of reactive powder and slag powder, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc. Reactivity, high reactivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

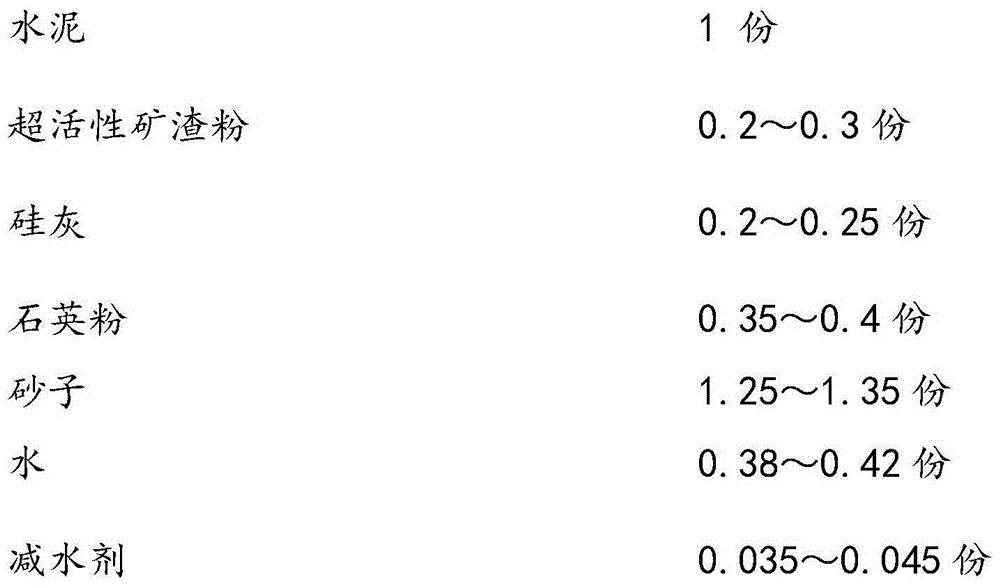

Method used

Image

Examples

Embodiment 1

[0058] The active powder concrete A in this implementation includes 1Kg cement, 0.32Kg super-active slag powder, 0.2Kg silica fume, 0.35Kg quartz powder, 1.25Kg natural river sand, 0.38Kg industrial water, 0.035Kg water reducing agent and preparation molding 1.5% of the volume of the final reactive powder concrete steel fiber; wherein the super-reactive slag powder is prepared by the following steps:

[0059] (1) Mix 64kg of slag powder with 12kg of the first grinding medium, wherein the first grinding medium is 4kg of Steel balls, and 1kg 2kg A mixture of steel columns; grinding in a ball mill for 55 minutes;

[0060] (2) Add 8kg of the second grinding medium to the step (1), wherein the second grinding medium has a diameter of The steel ball is continuously ground for 400 minutes to prepare the super-active slag powder of the present invention.

[0061] The preparation method of the reactive powder concrete in this embodiment is as follows:

[0062] (1) Dissolving the above-men...

Embodiment 2

[0066] The reactive powder concrete B described in this implementation includes 1kg cement, 0.2kg super-active slag powder, 0.21kg silica fume, 0.36kg quartz powder, 1.27kg natural river sand, 0.41kg industrial water, 0.037kg polycarboxylate for water reduction And steel fiber of 1.7% of the volume of the prepared reactive powder concrete;

[0067] Wherein, the super active slag powder is prepared through the following steps:

[0068] (1) Mix 4kg of S75 grade slag powder with 56kg of the first grinding medium, wherein the first grinding medium is 28kg Steel ball, 4kg Steel ball, 2kg Steel ball, 1.6kg Steel column, 2.4kg The mixture of the steel column is ground in a ball mill for 45 minutes;

[0069] (2) Add 24kg of the second grinding medium to the step (1), wherein the second grinding medium has a diameter of After grinding the steel balls for 480 minutes, the super-active slag powder of the present invention is prepared.

[0070] The preparation method of the reactive powder ...

Embodiment 3

[0078] The reactive powder concrete C in this implementation includes 1kg cement, 0.25kg super-active slag powder, 0.22Kg silica fume, 0.370Kg quartz powder, 1.28Kg natural river sand, 0.38Kg industrial water, 0.038Kg water reducing agent and preparation molding 1.8% steel fiber of the volume of the reactive powder concrete afterwards;

[0079] Wherein, the super active slag powder is prepared through the following steps:

[0080] (1) Mix 5kg of S95 grade slag powder with 16kg of the first grinding medium, wherein the first grinding medium is 6kg Steel ball, 2kg Steel ball, 2kg Steel ball, 2.6kg Steel column, 3.4kg The mixture of the steel column is ground in a ball mill for 60 minutes;

[0081] (2) Add 4kg of the second grinding medium to the step (1), wherein the second grinding medium has a diameter of The steel ball is continuously ground for 300 minutes to prepare the super-active slag powder of the present invention.

[0082] The preparation method of the reactive powder c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com