Method for preparing sodium stannate by utilizing tin-removed wastewater

A technology for tin stripping wastewater and sodium stannate, applied in chemical instruments and methods, tin compounds, water/sewage treatment and other directions, can solve problems such as unfavorable environmental protection, high roasting temperature, long reaction time, etc., and achieve good development prospects, The effect of reducing the roasting temperature and increasing the leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

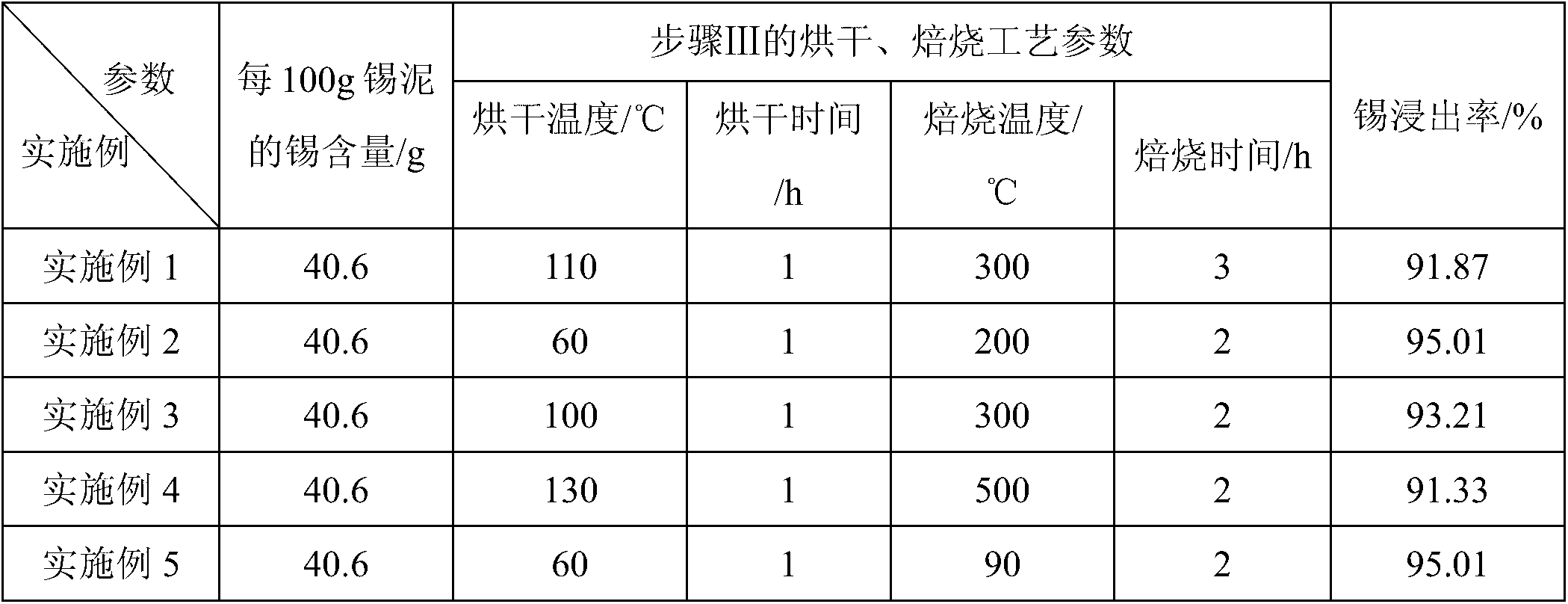

Examples

Embodiment 1

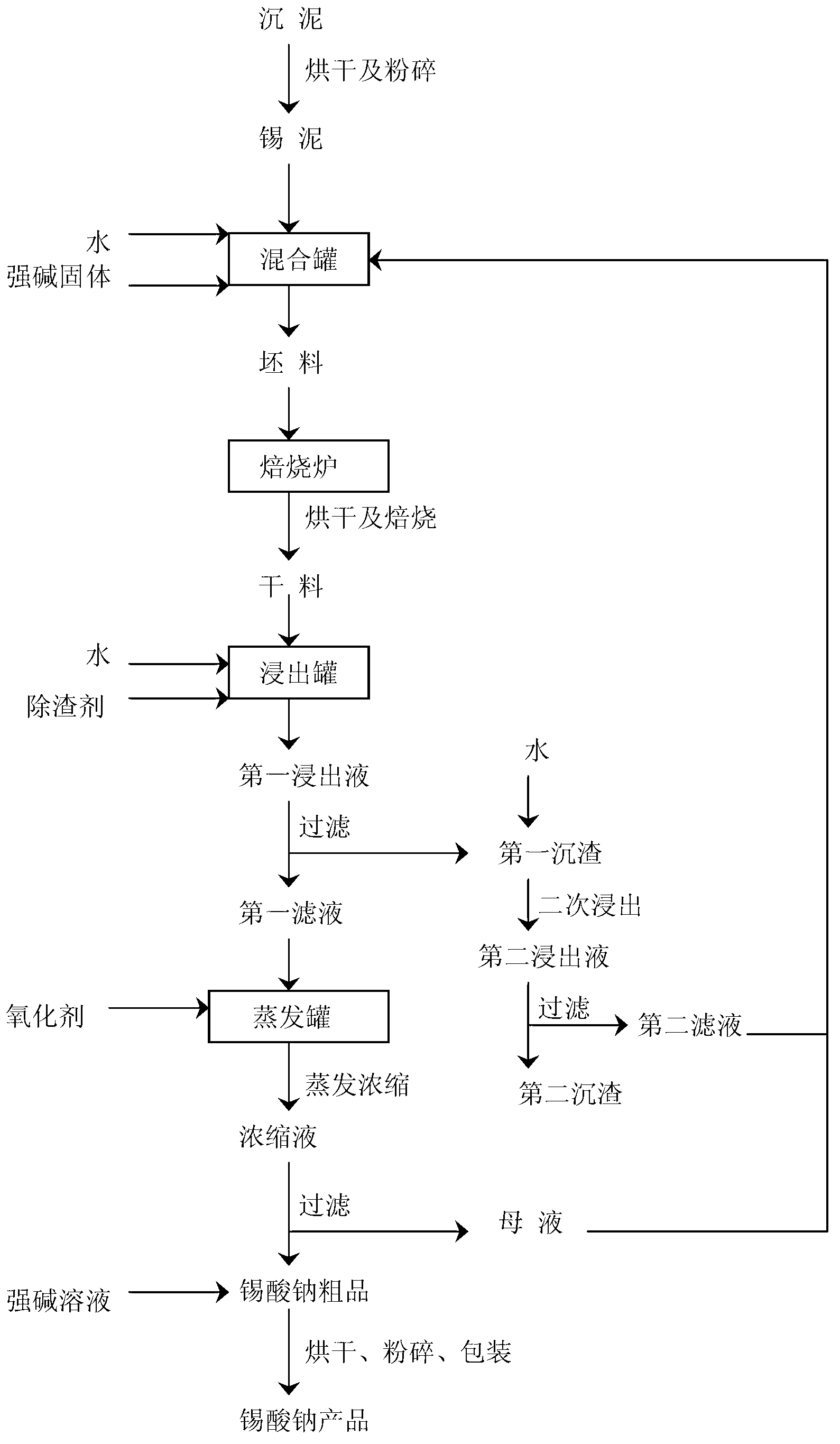

[0038] As shown in the figure, the method for preparing sodium stannate by utilizing tin stripping wastewater comprises the following steps:

[0039] 1. The tin stripping wastewater is subjected to precipitation treatment, and the filtered sludge is heated and dried at about 120°C. This step will affect the subsequent reaction quality, so it is necessary to ensure that the sludge is completely dry. The dried sludge is the tin sludge used as the raw material for the reaction, which is pulverized into powder by a pulverizer for later use. The chemical element analysis results of the sludge or tin sludge are shown in Table 1.

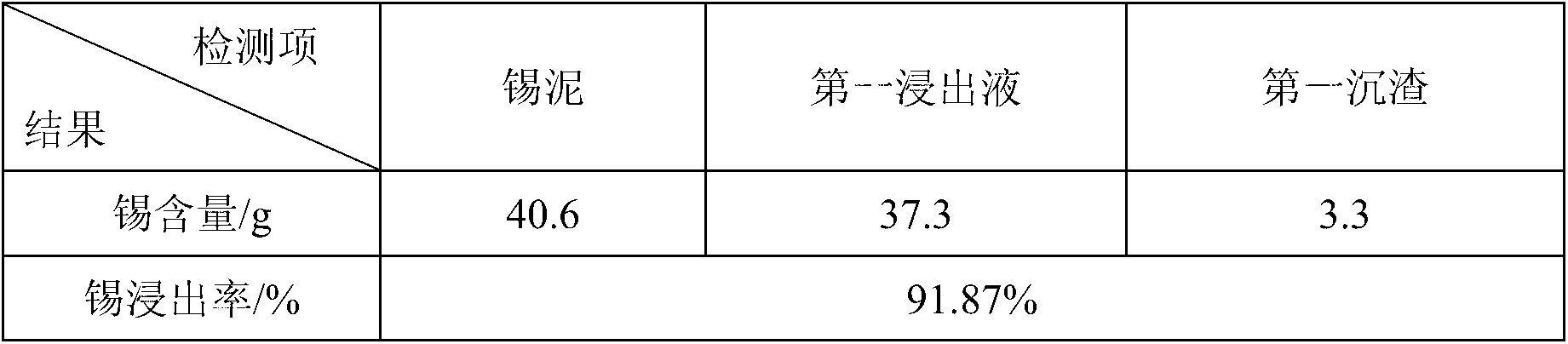

[0040] Table 1 Analysis results of chemical elements of sludge / tin sludge

[0041] detection item sn Pb Cu Fe As Sb organic matter Moisture* Ingredient content / % 40.6 0.00013 4.11 6.93 0.00024 0.000201 0.48 49.0

[0042] (*Except for "moisture" which is the test result of sedimentation, other test items are the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com