Method for preparing mesoporous molecular sieve

A technology of mesoporous molecular sieve and active ingredients is applied in the field of preparation of mesoporous molecular sieve MCM-48, which can solve the problems of raw material loss and cost increase, and achieve the effects of reducing preparation cost, reducing usage amount and avoiding toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

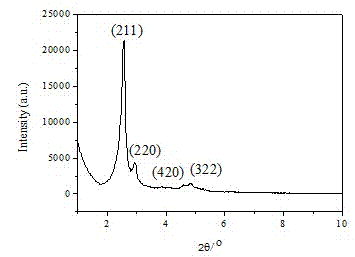

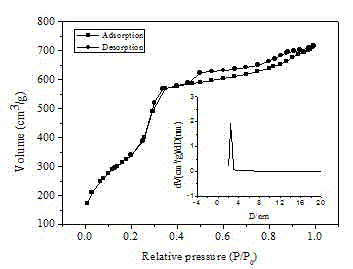

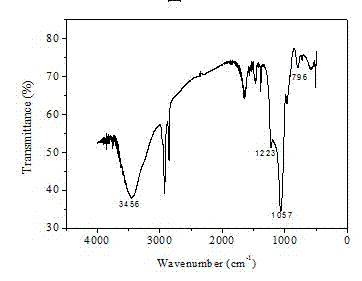

[0022] A preparation method of mesoporous molecular sieve MCM-48, which is characterized in that a single template agent CTAB is used to extract the active ingredients in fly ash as a silicon source, and under the activation of ethanol, it is synthesized by hydrothermal method in an alkaline medium MCM-48, the specific steps are as follows:

[0023] (1) Put the mixture composed of silicon-containing supernatant, template agent CTAB, absolute ethanol and water into the reactor, and stir slowly at 30~40°C until it is completely dissolved. After 2~3 hours of reaction, use H 2 SO 4 The solution adjusted the pH of the mixed solution to be 10.5, and continued to stir for 2 to 3 hours to obtain a white gel;

[0024] (2) Place the obtained white gel in a reaction kettle, control the temperature at 100-110°C, and conduct the crystallization reaction for 60-72 hours. After the reaction, filter and wash, dry to obtain a powdery solid, and roast the sample in a muffle furnace at 500°C A...

Embodiment 1

[0030] Prepare 1000ml of hydrochloric acid solution with a mass fraction of 20%, add 50g of fly ash, stir at a constant speed at 80°C for 4h, filter, wash until neutral, and dry 40g of fly ash for later use. Take 20g of NaOH, prepare 100ml of a solution with a concentration of 5mol / L, add 10g of iron-removing fly ash, stir and reflux at 80°C for 4 hours at normal pressure, then filter to obtain a silicon-containing supernatant (use ICP-AES to measure the silicon content in the supernatant). content), put it aside. According to the molar ratio of silicon-containing supernatant: grinding agent CTAB: absolute ethanol: water = 1:0.5:4.5:100, add reagents, mix and stir, and use 5mol / L H 2 SO 4 The solution adjusts the pH of the mixture to 10.5. Place the obtained white gel in a crystallization kettle, control the temperature at 100°C, and conduct the crystallization reaction for 72 hours, take it out to cool naturally, filter and wash, and dry to obtain a powdery solid. Roast th...

Embodiment 2

[0032] Take 0.05 g of the mesoporous material prepared in Example 1, and add it into 25 mL of an aqueous solution with a lead concentration of 100 mg / L. Finally, a lead removal rate of 95% can be obtained, and a good purification effect has been achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com