Method for preparing phenolic compound by liquefaction of salix mongolica

A technology of salix salix and phenols, which is applied in the field of resource utilization of salix salix, can solve problems such as difficult treatment, high chemical oxygen demand, and restrictions on large-scale promotion of hydrothermal liquefaction, and achieves simple operation, simplified process flow, and solution Effects of water scarcity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

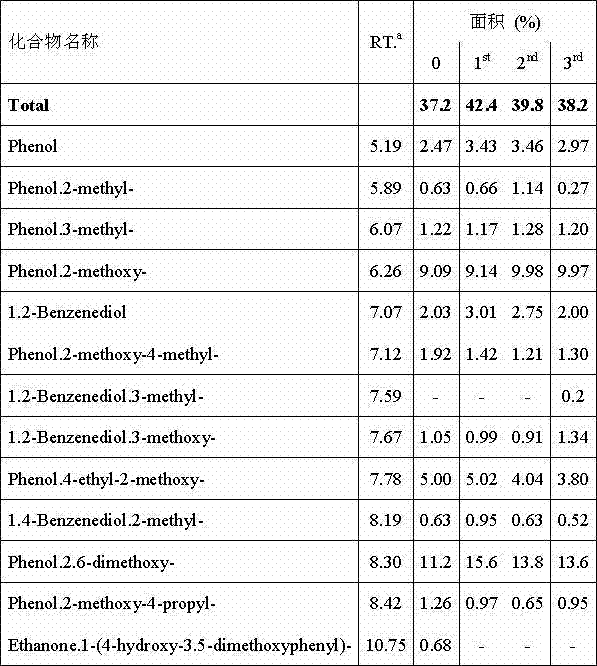

Embodiment 1

[0021] Grind Salix salix, pour 30g of Salix salix powder into a 250ml high-pressure reactor and add 150ml of distilled water, stir to make a slurry, and fill the reactor with 2MPa N 2 , heated to 300°C while stirring, kept for 10min, passed tap water to cool to room temperature, poured out the reaction mixture, and cleaned the kettle cavity with tetrahydrofuran; filtered the mixture into solid and liquid phases, and the liquid phase was process water. Extract the solid phase with 150ml of tetrahydrofuran, separate and extract the extract, filter the tetrahydrofuran phase with a Buchner funnel, and then distill under reduced pressure to recover tetrahydrofuran to obtain heavy oil; extract the process water with diethyl ether, and distill the diethyl ether phase under reduced pressure to recover diethyl ether That is, medium oil is obtained, and the water phase is the return water, which is reserved for the next experiment. Heavy and medium oils are rich in phenolic compounds. ...

Embodiment 2

[0023] Salix salix is crushed, 30g Salix salix powder is poured into a 250ml autoclave, the process water obtained in Example 1 is added as a medium, stirred to form a slurry, and 2MPa N 2 , heated to 300°C while stirring, kept for 10min, passed tap water to cool to room temperature, poured out the reaction mixture, and cleaned the kettle cavity with tetrahydrofuran; filtered the mixture into solid and liquid phases, and the liquid phase was process water. Extract the solid phase with 150ml of tetrahydrofuran, separate and extract the extract, filter the tetrahydrofuran phase with a Buchner funnel, and then distill under reduced pressure to recover tetrahydrofuran to obtain heavy oil. The process water is directly added to another reactor as the liquefaction medium for the next hydrothermal liquefaction reaction, and the above process is repeated once to obtain the heavy oil and process water after the process water is reused once. Finally, extract the process water with die...

Embodiment 3

[0025] Salix salix is crushed, 30g Salix salix powder is poured into 250ml of high pressure and added the process water of Example 12 as a medium, stirred to form a slurry, and 2MPa N 2 , heated to 300°C while stirring, kept for 10min, passed tap water to cool to room temperature, poured out the reaction mixture, and cleaned the kettle cavity with tetrahydrofuran; filtered the mixture into solid and liquid phases, and the liquid phase was process water. Extract the solid phase with 150ml of tetrahydrofuran, separate and extract the extract, filter the tetrahydrofuran phase with a Buchner funnel, and then distill under reduced pressure to recover tetrahydrofuran to obtain heavy oil. The process water is directly added to another reactor as the liquefaction medium for the next hydrothermal liquefaction reaction, and the above process is repeated twice to obtain the heavy oil and process water after the process water is reused twice. Finally, extract the process water with diet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com