Polyurethane elastomer composite material with low modulus and high dielectric constant, and preparation method of composite material

A technology of polyurethane elastomer and composite material is applied in the field of dielectric elastomer preparation to achieve the effect of improving movement ability and polarization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

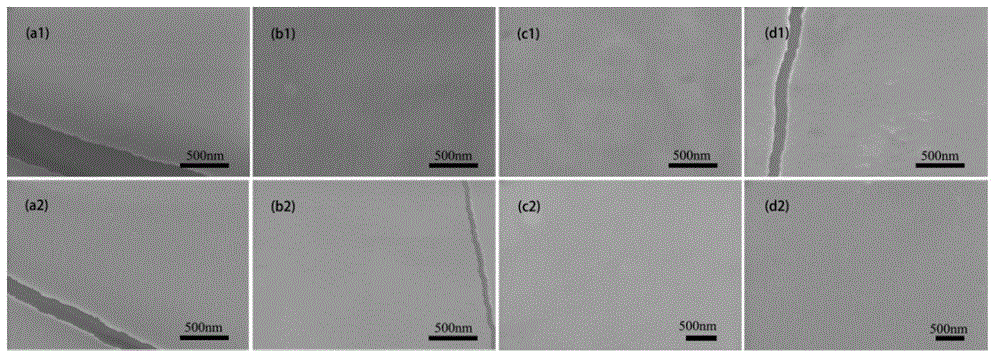

Image

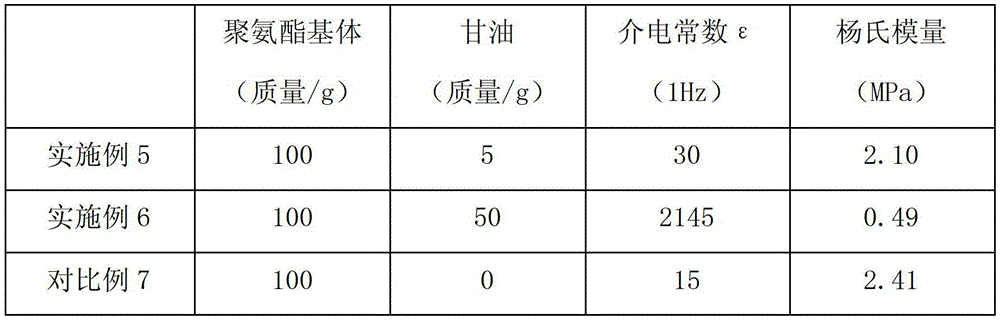

Examples

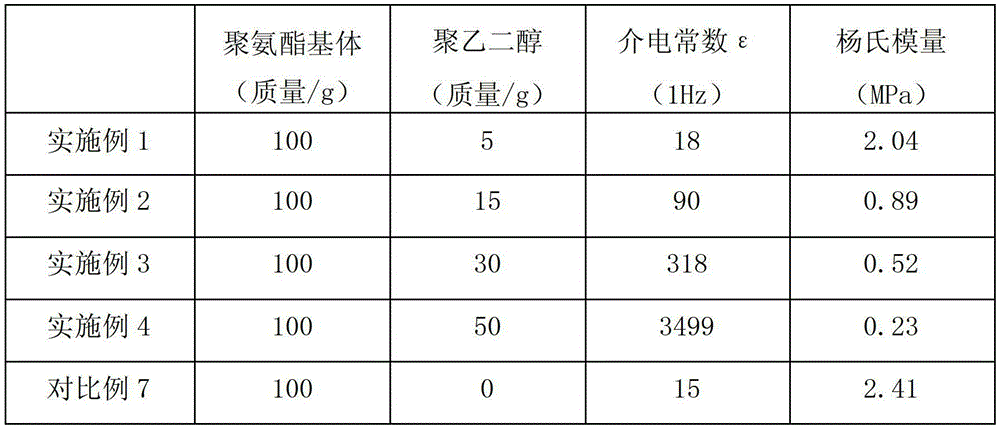

Embodiment 1

[0022] Using polyurethane elastomer as a matrix and polyethylene glycol as an organic small molecule filler, a polyurethane elastomer molecular composite material with low modulus and high dielectric constant is prepared. The specific operation steps are: (1) Dissolve 100g of thermoplastic polyurethane elastomer in In 1500g of tetrahydrofuran, heat and stir at 66°C to dissolve into a transparent solution; (2) Add 5g of polyethylene glycol small molecule filler with a molecular weight of 600, continue heating and stirring until the polyethylene glycol is completely dissolved; (3) Pour the solution into a thick In a square mold with a diameter of 2 cm and a length of 8 cm, place it in a ventilation device for 6 hours, and after the solvent in the solution is completely volatilized, a polyurethane elastomer molecular composite material with low modulus and high dielectric constant is obtained.

[0023] The thermoplastic polyurethane elastomer used above is Soft45A polyester poly...

Embodiment 2

[0027] Using polyurethane elastomer as a matrix and polyethylene glycol as an organic small molecule filler, a polyurethane elastomer molecular composite material with low modulus and high dielectric constant is prepared. The specific operation steps are: (1) Dissolve 100g of thermoplastic polyurethane elastomer in In 1800g tetrahydrofuran, heat and stir at 66°C to dissolve into a transparent solution; (2) Add 15g of polyethylene glycol small molecule filler with a molecular weight of 600, continue heating and stirring until the polyethylene glycol is completely dissolved; (3) Pour the solution into a thickness of In a square mold with a length of 2 cm and a length of 8 cm, place it in a ventilation device for 6 hours. After the solvent in the solution is completely volatilized, a polyurethane elastomer molecular composite material with low modulus and high dielectric constant is obtained.

[0028] The thermoplastic polyurethane elastomer used above is Soft45A polyester polyu...

Embodiment 3

[0032] Using polyurethane elastomer as a matrix and polyethylene glycol as an organic small molecule filler, a polyurethane elastomer molecular composite material with low modulus and high dielectric constant is prepared. The specific operation steps are: (1) Dissolve 100g of thermoplastic polyurethane elastomer in In 2000g acetone, heat and stir at 56°C to dissolve into a transparent solution; (2) Add 30 parts by mass of polyethylene glycol small molecule filler with a molecular weight of 200, and continue heating and stirring until the polyethylene glycol is completely dissolved; (3) Pour the solution into In a square mold with a thickness of 2 cm and a length of 8 cm, place it in a ventilation device for 6 hours. After the solvent in the solution is completely volatilized, a polyurethane elastomer molecular composite material with low modulus and high dielectric constant is obtained.

[0033] The thermoplastic polyurethane elastomer used above is Soft45A polyester polyuret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com