Method for manufacturing polyethylene fiber for fishing

A technology of polyethylene fiber and manufacturing method, which is applied in the direction of single-component polyolefin rayon, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems of increased production cost, poor softness and nodular strength of polyethylene fiber, and poly Poor toughness of vinyl fibers and other problems, to achieve the effect of low production cost, cost reduction and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment (1)

[0007] A polyethylene fiber for fishing is composed of the following components by mass percentage (see Table 1):

[0008] Table 1

[0009] name

Substance name

Dosage

polyethylene

High-density polyethylene

80

elastomer

Ethylene-octene copolymer (POE)

14

active nanoparticles

5

Phosphite Antioxidants

0.5

hydrocarbon lubricants

0.5

[0010] A kind of manufacturing method of polyethylene fiber for fishery is carried out according to the following steps:

[0011] (1) The elastomer / active nanoparticle compound system is prepared by blending the active nanoparticles and the elastomer according to the mass ratio. The residence time of the material in the screw extruder is 2-3 minutes, and the temperature is 150-250°C.

[0012] (2) Mix the prepared compound system with polyethylene and granulate it through a twin-screw extruder to obtain mast...

Embodiment (2)

[0015] A polyethylene fiber for fishing is composed of the following components by mass percentage (see Table 2):

[0016] Table 2

[0017] name

Substance name

Dosage

polyethylene

High-density polyethylene

80

elastomer

EPDM

10

active nanoparticles

9

Phosphite Antioxidants

0.5

hydrocarbon lubricants

0.5

[0018] A method for manufacturing polyethylene fiber for fishing, which is carried out in the following steps:

[0019] (1) The elastomer / active nanoparticle compound system is prepared by blending the active nanoparticles and the elastomer according to the mass ratio. The residence time of the material in the screw extruder is 2-3 minutes, and the temperature is 150-250°C.

[0020] (2) Mix the prepared compound system with polyethylene and granulate it through a twin-screw extruder to obtain master batches. The residence time of the...

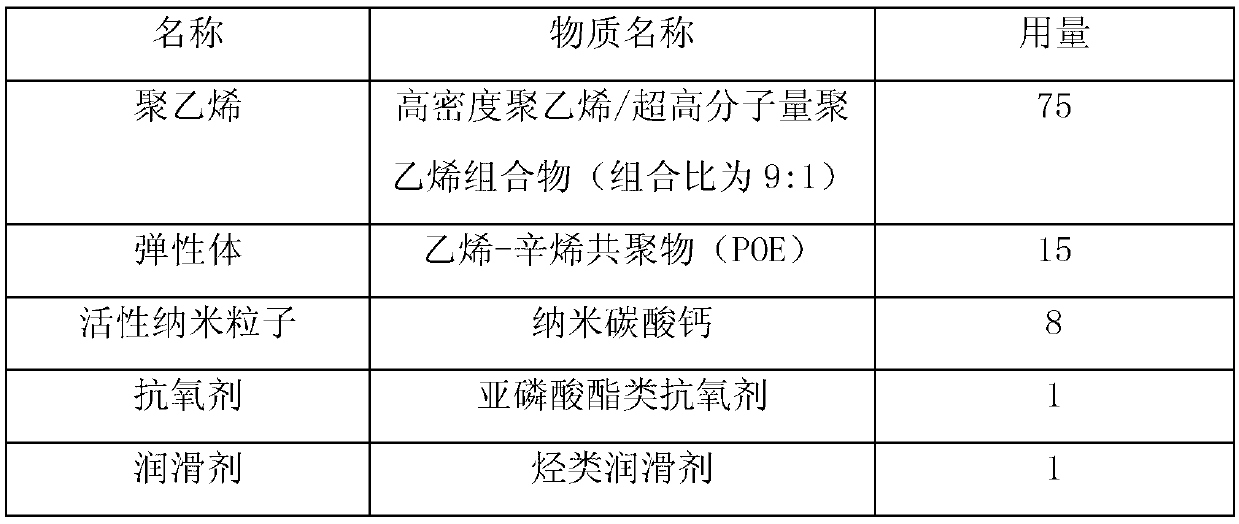

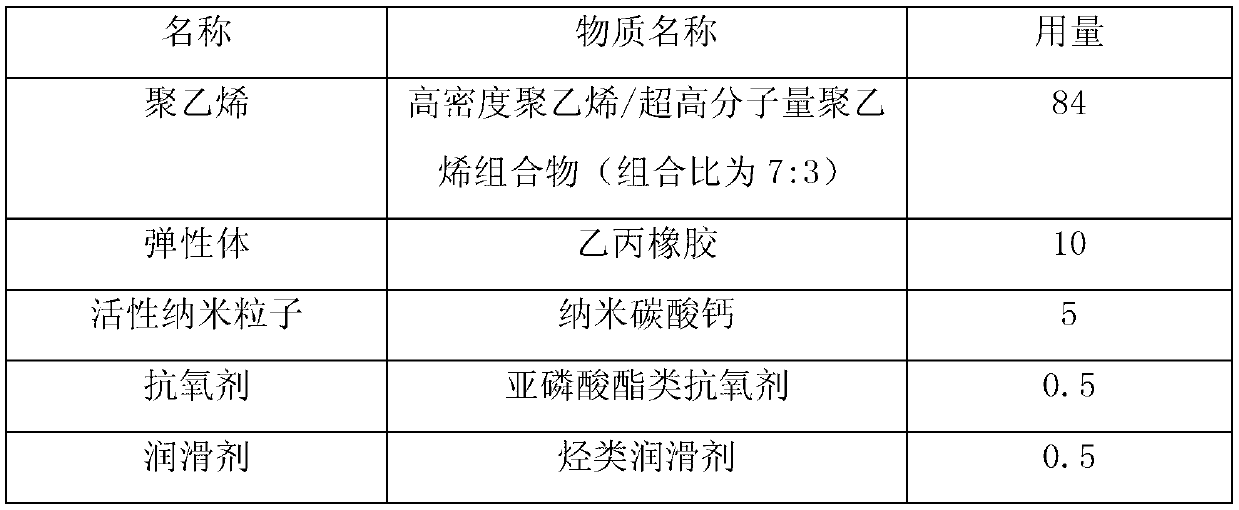

Embodiment (3)

[0023] A polyethylene fiber for fishing is composed of the following components by mass percentage (see Table 3):

[0024] table 3

[0025]

[0026] A kind of polyethylene fiber and its manufacture method, carry out according to the following steps:

[0027] (1) The elastomer / active nanoparticle compound system is prepared by blending the active nanoparticles and the elastomer according to the mass ratio. The residence time of the material in the screw extruder is 2-3 minutes, and the temperature is 150-250°C.

[0028] (2) Mix the prepared compound system with polyethylene and granulate it through a twin-screw extruder to obtain master batches. The residence time of the material in the screw extruder is 2-3 minutes, and the temperature is 150-250 ℃.

[0029] (3) Mix the obtained masterbatch with polyethylene and then melt spinning-high-strength drafting process to obtain high-strength and high-toughness polyethylene fibers. The process of melt spinning and high-strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com