Preparation method of black yttrium oxide (Y2O3) ceramic coating

A Y2O3, ceramic coating technology, applied in coating, metal material coating process, fusion spraying and other directions, can solve problems such as high cost, limited life of parts, peeling of process cavity wall coating, etc., to achieve low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

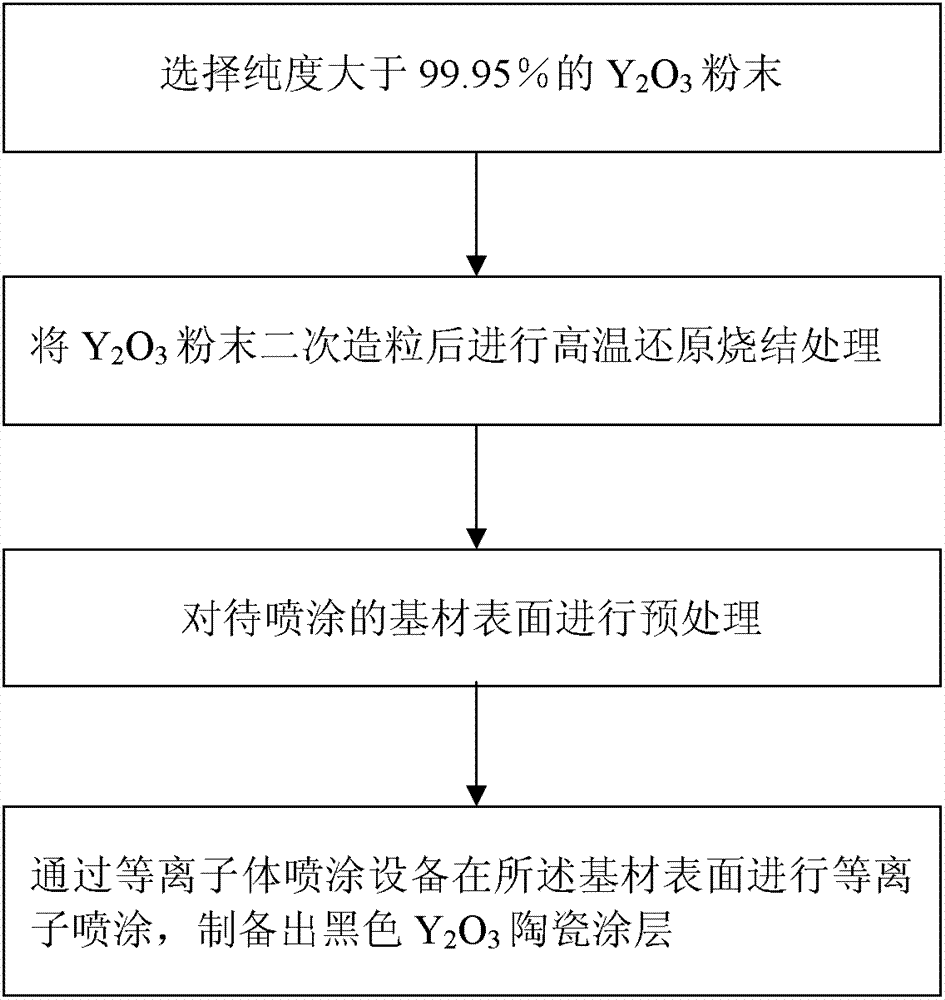

[0029] like figure 1 As shown, the embodiment of the present invention provides a black Y 2 o 3A method for preparing a ceramic coating, specifically comprising the steps of:

[0030] (1) Select Y with a purity greater than 99.95% 2 o 3 Powder, the original particle size of the powder is 40-60nm, the original Y 2 o 3 The powder is prepared into a slurry through an organic adhesive, and the fine powder is aggregated together by a granulation device to form spherical particles. The particle size range of the secondary granulation is 5-60 μm; the powder after the secondary granulation is The spherical shape of the porous structure is a hollow micron ball assembled by small nano-particles, which has excellent fluidity;

[0031] (2) Y after secondary granulation 2 o 3 The powder is placed in a reaction furnace or an annea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com