Deep treatment process for coal-to-liquids wastewater

An advanced treatment and coal-to-oil technology, which is applied in the directions of water/sewage multi-stage treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of high operating costs, harsh conditions, and few applications. Achieve the effects of low operating cost, small footprint and good economic applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

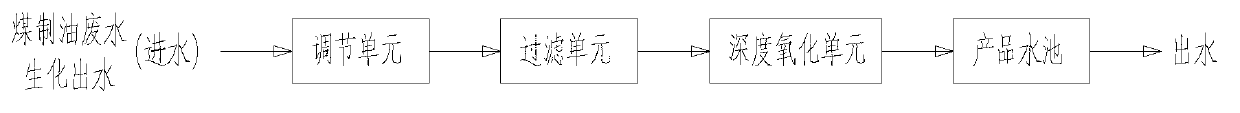

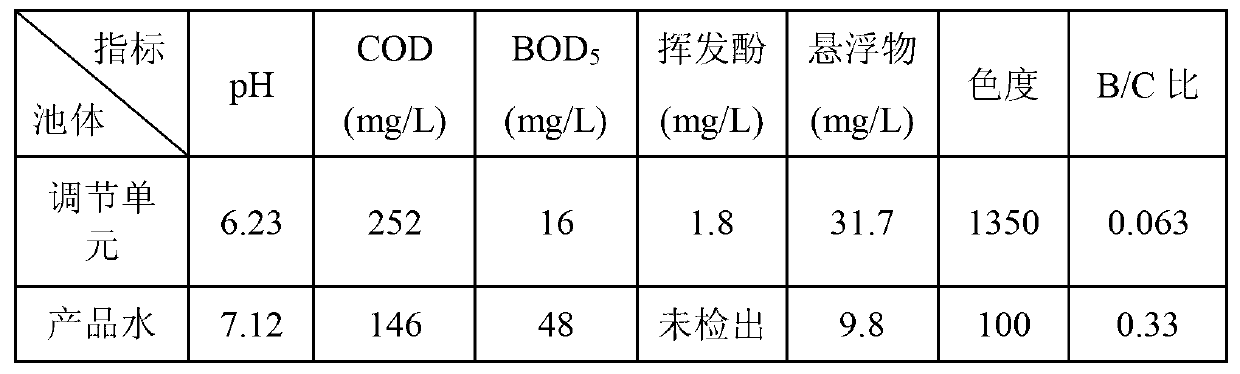

[0019] A case of advanced treatment of coal-to-oil wastewater in Inner Mongolia. The advanced treatment process flow chart of coal-to-oil wastewater is as follows figure 1 shown.

[0020] The effluent of high-concentration coal-to-oil waste water is pumped into the adjustment unit through the water pump for homogeneity and equalization through the biochemical treatment. The acid and alkali metering pumps are linked with the pH meter to control the pH value of the influent water at 6.23, and assist mechanical stirring to maintain uniform water quality. The time is 2.1h; the outlet water of the adjustment unit is lifted by the pump to the filter unit to remove SS and insoluble COD in the wastewater. The filter material is made of high-grade quartz sand, and the filtration rate is controlled at 4m / h; the filtered water still has a certain pressure and directly enters the ozone oxidation Unit, during the oxidation reaction process, the ratio (mass ratio) of the dosage of ozone to...

Embodiment 2

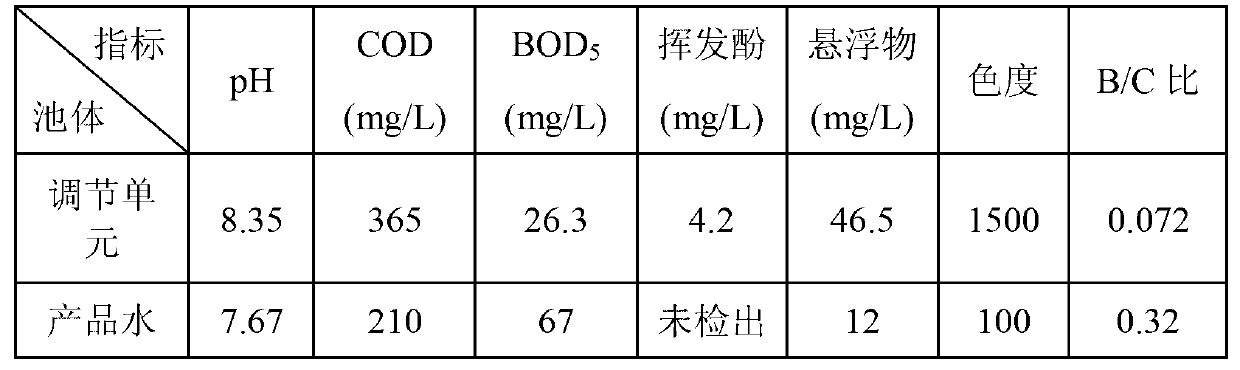

[0024] In the adjustment unit, the metering pump is linked with the pH meter to control the pH value of the incoming water at 8.35, and the mechanical stirring is assisted to keep the water quality uniform, and the residence time is 4h; the filter material of the filter unit is fiber ball, and the filtration rate is controlled at 6m / h; the ozone oxidation unit Control the ratio (mass ratio) of the dosage of ozone to the total amount of COD in the ozone oxidation water to be 1.2:1, and the reaction time is 1.2h; the deeply oxidized effluent enters the product pool, and the water quality in the pool is linked with the pH through the metering pump to control the pH value of the product water at 7.67, residence time 4h. All the other are identical with embodiment 1, and concrete treatment effect is shown in table 2.

[0025] Attached Table 2 Advanced treatment results of a certain coal-to-oil wastewater in Inner Mongolia 2

[0026]

Embodiment 3

[0028] In the adjustment unit, the metering pump is linked with the pH meter to control the pH value of the incoming water at 9.87, and the mechanical stirring is assisted to keep the water quality uniform, and the residence time is 12 hours; the filter material of the filter unit is filtered by a microfiltration filter element; the ozone oxidation unit controls the dosage of ozone The total ratio (mass ratio) of COD in the ozone oxidation water is 4:1, and the reaction time is 2.8 hours; the deeply oxidized water enters the product pool, and the water quality in the pool is linked with the pH through the metering pump to control the pH value of the product water at 7.81, and the residence time is 8 hours. All the other are identical with embodiment 1, and concrete treatment effect is shown in table 3.

[0029] Attached Table 3 Advanced treatment results of a certain coal-to-oil wastewater in Inner Mongolia 3

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com