Sliced method of polycrystalline silicon solar cell

A technology for solar cells and polysilicon, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of low average conversion efficiency of solar cells and fine grains of silicon wafers, and achieves reduction of operation steps and improvement of minority carrier life. , the effect of eliminating negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

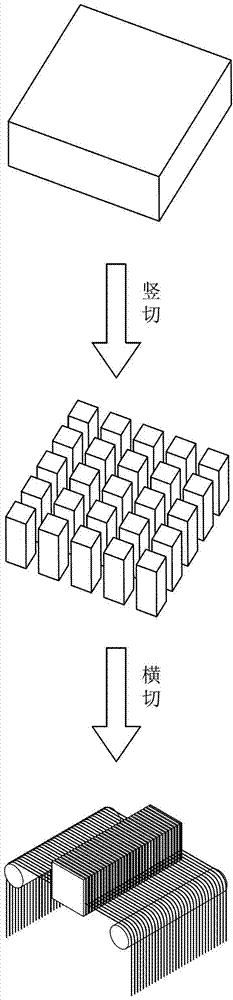

Method used

Image

Examples

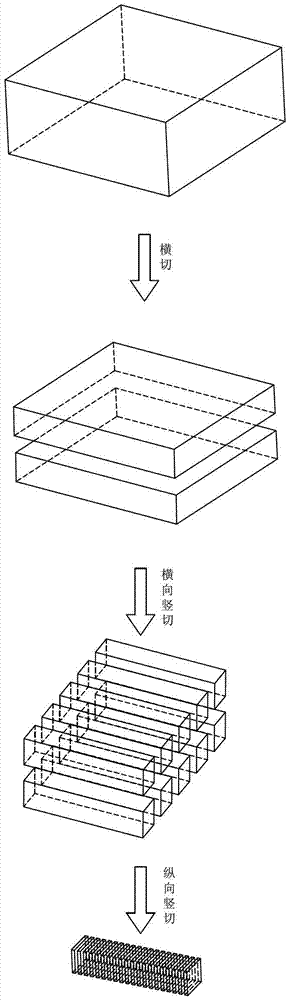

Embodiment 1

[0028] Example 1: A silicon ingot with a specification of 80 (length) × 80 (width) × 32 (height) cm is first cross-cut into two uniform upper and lower parts, that is, the size of each part is 80 (length) × 80 (width) )×16 (height) cm, and cut 4 horizontally and vertically at equal intervals to form 2×5=10 small ingots of equal volume, and finally cut each small ingot vertically and vertically with a multi-wire cutting machine to form several 6 inches of 0.18-0.22mm thick silicon wafers. The minority carrier lifetime of the silicon wafer is measured to be 21us. When it is made into a solar cell, the Voc of the solar cell is 626mv, the Isc is 8.64A, and the average conversion efficiency of the cell is 17.51%.

Embodiment 2

[0029] Example 2: A silicon ingot with a specification of 64 (length) × 64 (width) × 26 (height) cm is first cross-cut into two uniform upper and lower parts, that is, the size of each part is 64 (length) × 64 (width) )×13 (height) cm, and cut 4 horizontally and vertically at equal intervals to form 2×5=10 small ingots of equal volume, and finally cut each small ingot vertically and vertically with a multi-wire cutting machine to form several 5 pieces inches of 0.18-0.22mm thick silicon wafers. The minority carrier lifetime of the silicon wafer is measured to be 23us. When it is made into a solar cell, the Voc of the solar cell is 626mv, the Isc is 8.66A, and the average conversion efficiency of the cell is 17.52%.

Embodiment 3

[0030] Example 3: A silicon ingot with a specification of 48 (length) × 48 (width) × 32 (height) cm is first cross-cut into two uniform upper and lower parts, that is, the size of each part is 48 (length) × 48 (width) )×16 (height) cm, and then cut 2 horizontally and vertically at equal intervals to form 2×3=6 small ingots of equal volume, and finally cut each small ingot vertically and vertically with a multi-wire cutting machine to form several 6 inches of 0.18-0.22mm thick silicon wafers. The minority carrier lifetime of the silicon wafer is measured to be 20us, and it is made into a solar cell. The Voc of the solar cell is 625mv, the Isc is 8.63A, and the average conversion efficiency of the cell is 17.50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Life expectancy | aaaaa | aaaaa |

| Life expectancy | aaaaa | aaaaa |

| Life expectancy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com