Amorphous alloy inoculation method for treating cast aluminum alloy

A technology for casting aluminum alloys and amorphous alloys, which is applied in the field of amorphous alloy inoculation treatment of cast aluminum alloys, to achieve the effects of easy dispersion and uniformity, small burning loss, and shortened solidification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

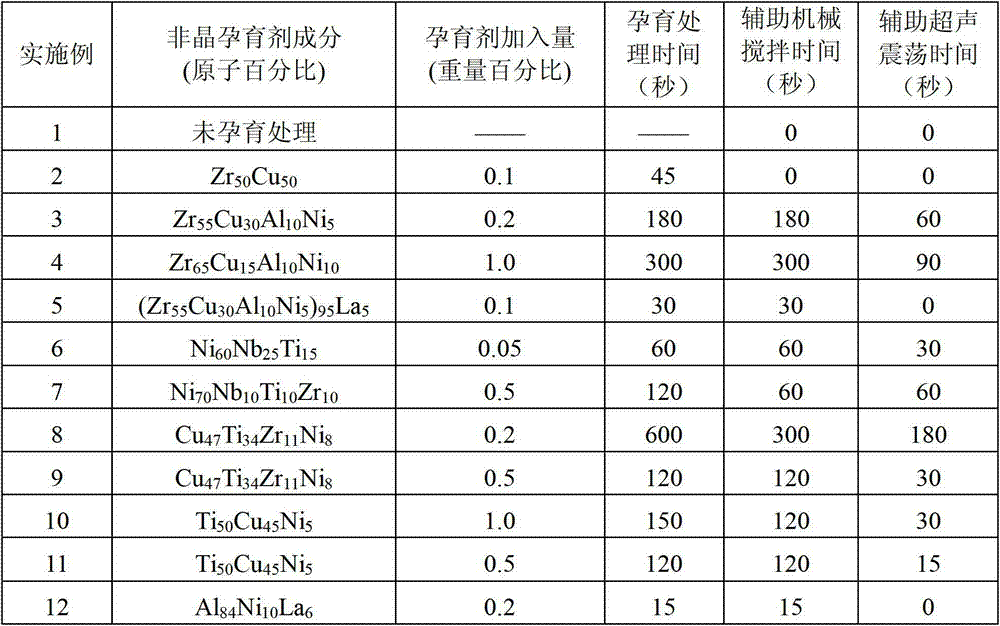

[0060] 2, the preparation of amorphous alloy inoculant in the above-mentioned embodiment:

[0061] Firstly, the ingredients are prepared according to the composition of the inoculant, and the prepared alloy is put into the water-cooled copper crucible in the melting chamber of the electric arc furnace. Before smelting, the vacuum degree of the electric arc furnace smelting chamber is pumped to a vacuum state of 0.006-0.008Pa, and then 0.05-0.06MPa high-purity argon gas is introduced into the smelting vacuum chamber, under the protection of high-purity argon gas absorbing oxygen from Ti, Use electric arc to smelt the inoculant of the present invention in a water-cooled copper crucible, the smelting current is 250-350A, smelt for 3-4 minutes, turn over, add electromagnetic stirring during the smelting process, turn over and smelt repeatedly 4-5 times, so that the composition of the alloy is uniform . Finally, start the vacuum pump to suck the alloy liquid in the crucible into t...

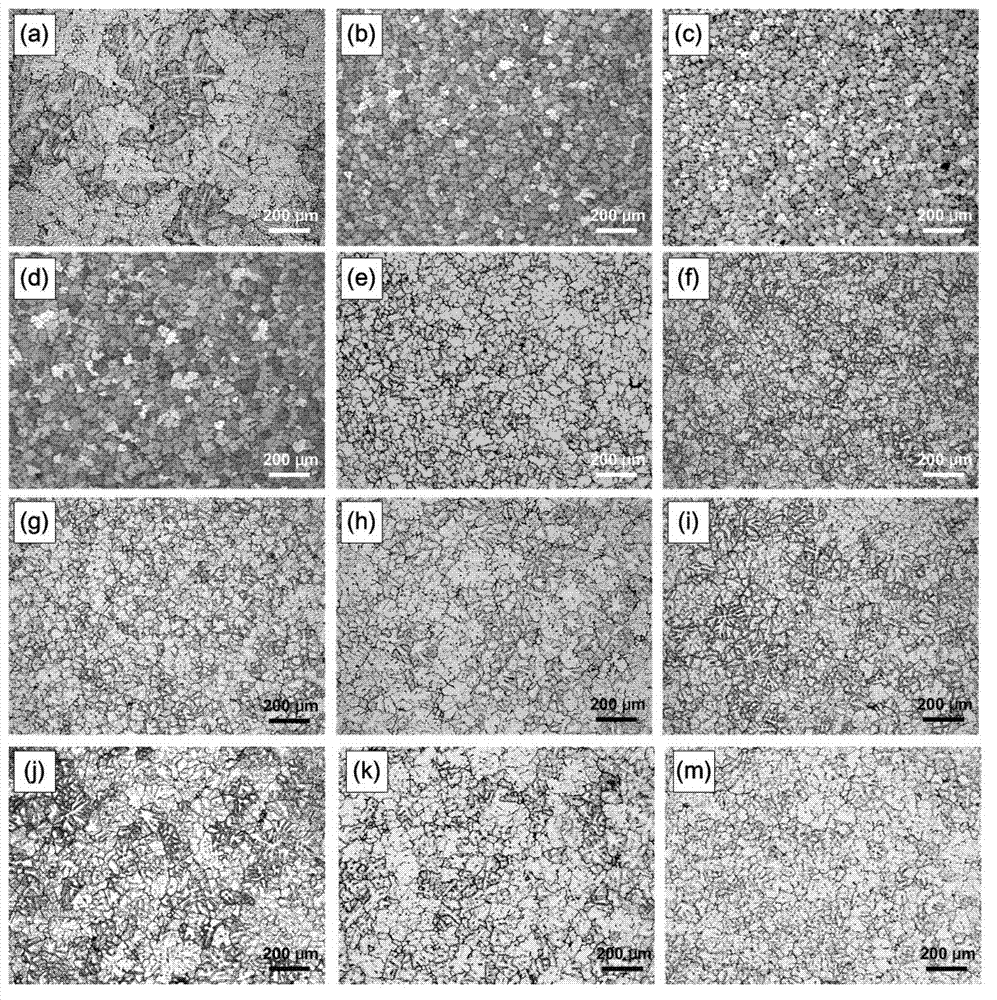

Embodiment 2-12

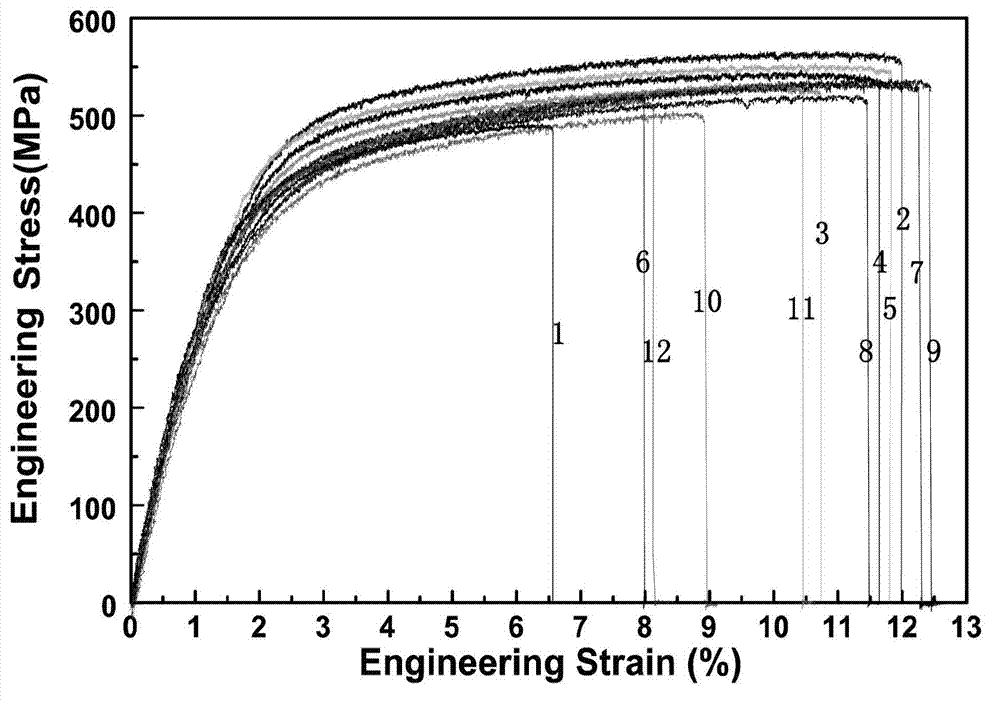

[0065] figure 1 (a) is an aluminum alloy without amorphous inoculation treatment (Example 1) and (b-m) an aluminum alloy treated with Zr series, Ni series, Cu series, Ti series and Al series amorphous alloy inoculants (Example 2 -12) as-cast microstructure (optical microscope photo). Figure 1 shows that the as-cast microstructure grain size of the aluminum alloy without inoculation treatment is relatively thick, and the grain size is mostly at 150-250 microns, while the aluminum alloys treated with different alloy system amorphous alloy inoculants (Example 2-12) The as-cast microstructure has been unexpectedly refined, and the grain size is mostly between 35-150 microns. Compared with the as-cast structure of the aluminum alloy without amorphous inoculation treatment, the grains are refined to its 3 / 5 or even 1 / 4 of that. And most of them are approximately equiaxed crystals with uniform structure. figure 2 Curves 1-12 are tensile engineering stress-strain curves of non-ino...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com