Medium and low temperature solid oxide fuel cell cathode material

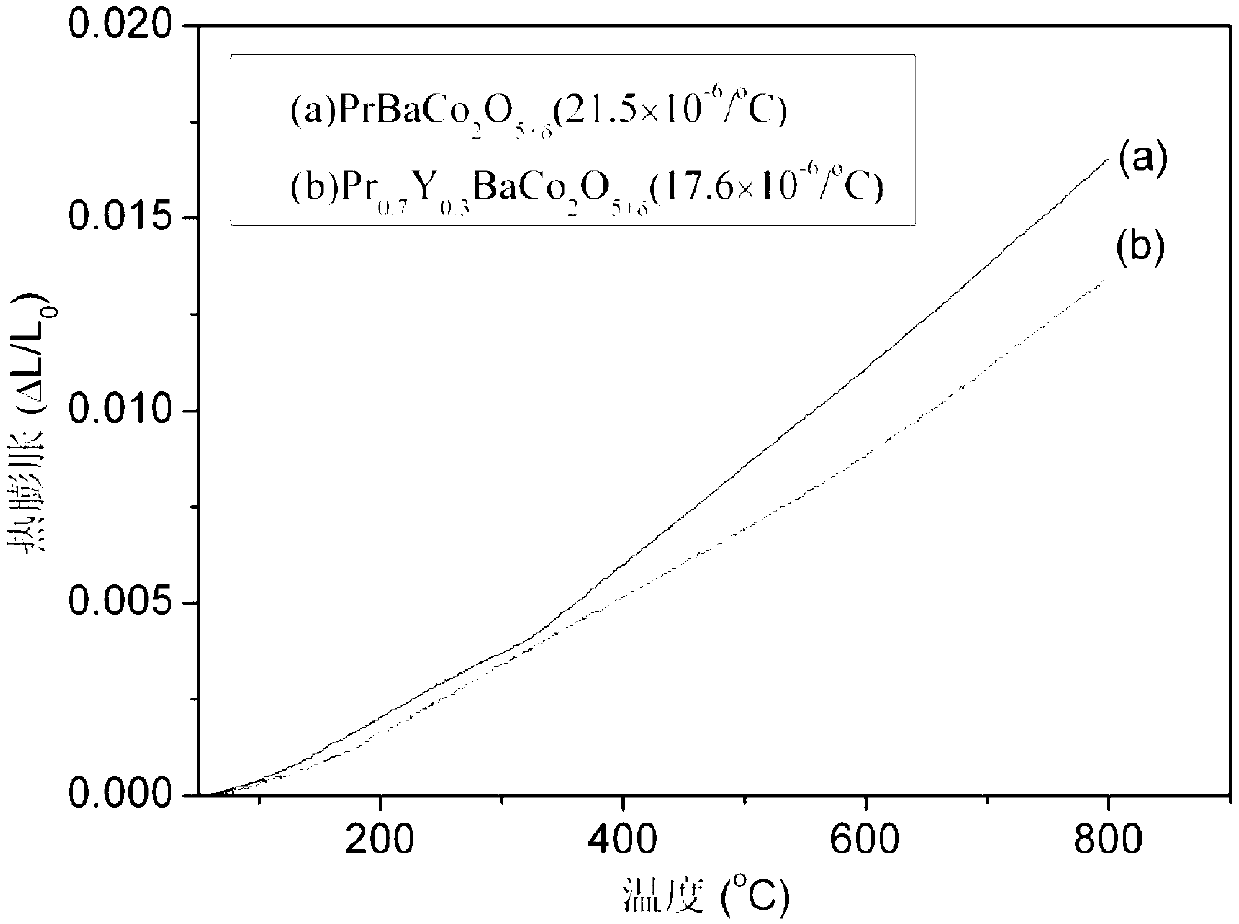

A fuel cell cathode, solid oxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high thermal expansion coefficient and oxygen loss, and achieve the effect of high electrical conductivity and low thermal expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

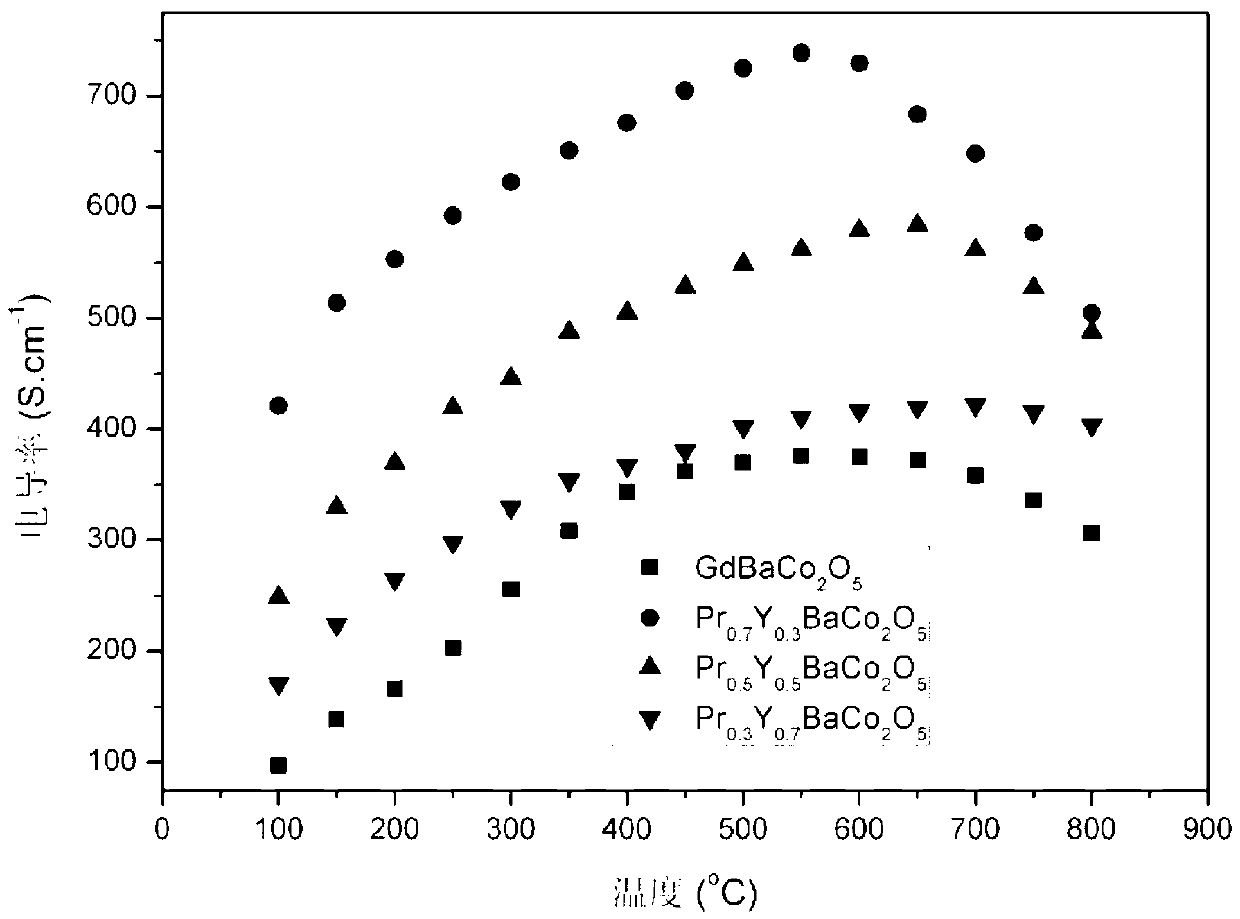

[0020] Example 1 : 0.02 mol Pr 0.7 Y 0.3 BaCo 2 o 5+δ Synthesis, conductivity test and impedance test.

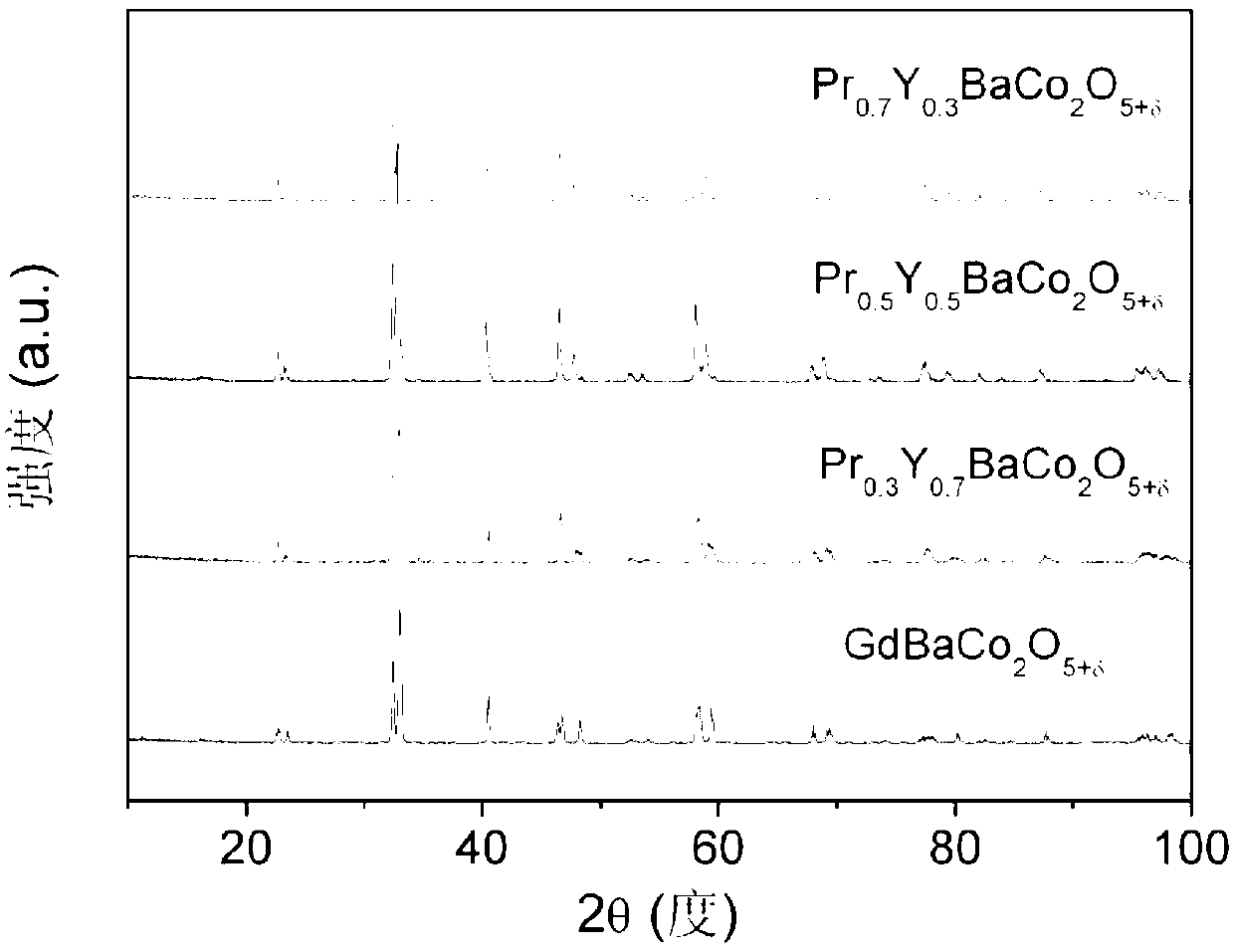

[0021] Weigh 2.38 g Pr 6 o 11 (analytically pure), 0.68 g Y 2 o 3 (analytical grade), 3.94 g BaCO 3 (analytical pure), 9.96 g C 4 h 6 o 4 Co 4H 2 O (analytically pure). Grind the above materials in a ball mill jar for 4 hours to make them evenly mixed, using agate balls as grinding media, and alcohol as a dispersant. Dry the uniformly mixed slurry, and the dried material is at 1000 o C was calcined for 10 hours to obtain the desired cathode material Pr 0.7 Y 0.3 BaCo 2 o 5+δ . The prepared powder is determined by XRD powder diffraction method to be a tetragonal double perovskite structure, such as figure 1 shown.

[0022] Add 1% (mass ratio) of PVA to the prepared powder, mix and dry, dry press at 110 MPa, and dry in air at 1200 o C was calcined for 10 hours to obtain a dense cathode material, which can be used for the determination of electrical cond...

Embodiment 2

[0024] Example 2 : 0.02 mol Pr 0.5 Y 0.5 BaCo 2 o 5+δ Synthesis, conductivity test and impedance test.

[0025] Weigh 1.7 g Pr 6 o 11 (analytically pure), 1.12 g Y 2 o 3 (analytical grade), 3.94 g BaCO 3 (analytical pure), 9.96 g C 4 h 6 o 4 Co 4H 2 O (analytically pure). Grind the above materials in a ball mill jar for 4 hours to make them evenly mixed, using agate balls as grinding media, and alcohol as a dispersant. Dry the uniformly mixed slurry, and the dried material is at 1000 o C was calcined for 10 hours to obtain the desired cathode material Pr 0.5 Y 0.5 BaCo 2 o 5+δ . The prepared powder is determined by XRD powder diffraction method to be a tetragonal double perovskite structure, such as figure 1 shown.

[0026] Add 1% (mass ratio) of PVA to the prepared powder, mix and dry, dry press at 110 MPa, and dry in air at 1200 o C was calcined for 10 hours to obtain a dense cathode material, which can be used for the determination of electrical condu...

Embodiment 3

[0028] Example 3 : 0.02 mol Pr 0.3 Y 0.7 BaCo 2 o 5+δ Synthesis, conductivity test and impedance test.

[0029] Weigh 1.02 g Pr 6 o 11 (analytically pure), 1.58 g Y 2 o 3 (analytical grade), 3.94 g BaCO 3 (analytical pure), 9.96 g C 4 h 6 o 4 Co 4H 2 O (analytically pure). Grind the above materials in a ball mill jar for 4 hours to make them evenly mixed, using agate balls as grinding media, and alcohol as a dispersant. Dry the uniformly mixed slurry, and the dried material is at 1000 o C was calcined for 10 hours to obtain the desired cathode material Pr 0.3 Y 0.7 BaCo 2 o 5+δ . The prepared powder is determined by XRD powder diffraction method to be a tetragonal double perovskite structure, such as figure 1 shown.

[0030] Add 1% (mass ratio) of PVA to the prepared powder, mix and dry, dry press at 110 MPa, and dry in air at 1200 o C was calcined for 10 hours to obtain a dense cathode material, which can be used for the determination of electrical cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com