Formation method of metal grid electrode

A metal gate and metal gate technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problem that the metal gate is difficult to meet the process requirements, and achieve the goal of improving process integration and saving process steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

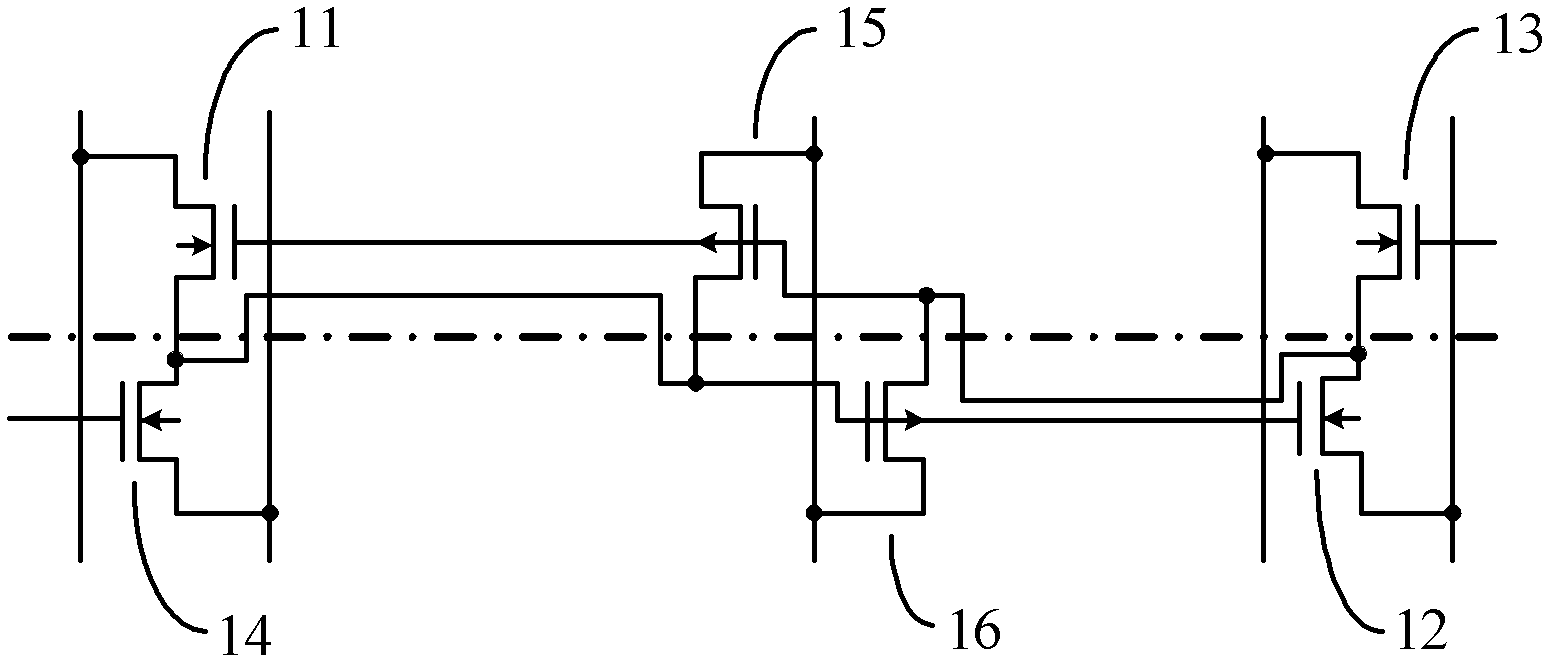

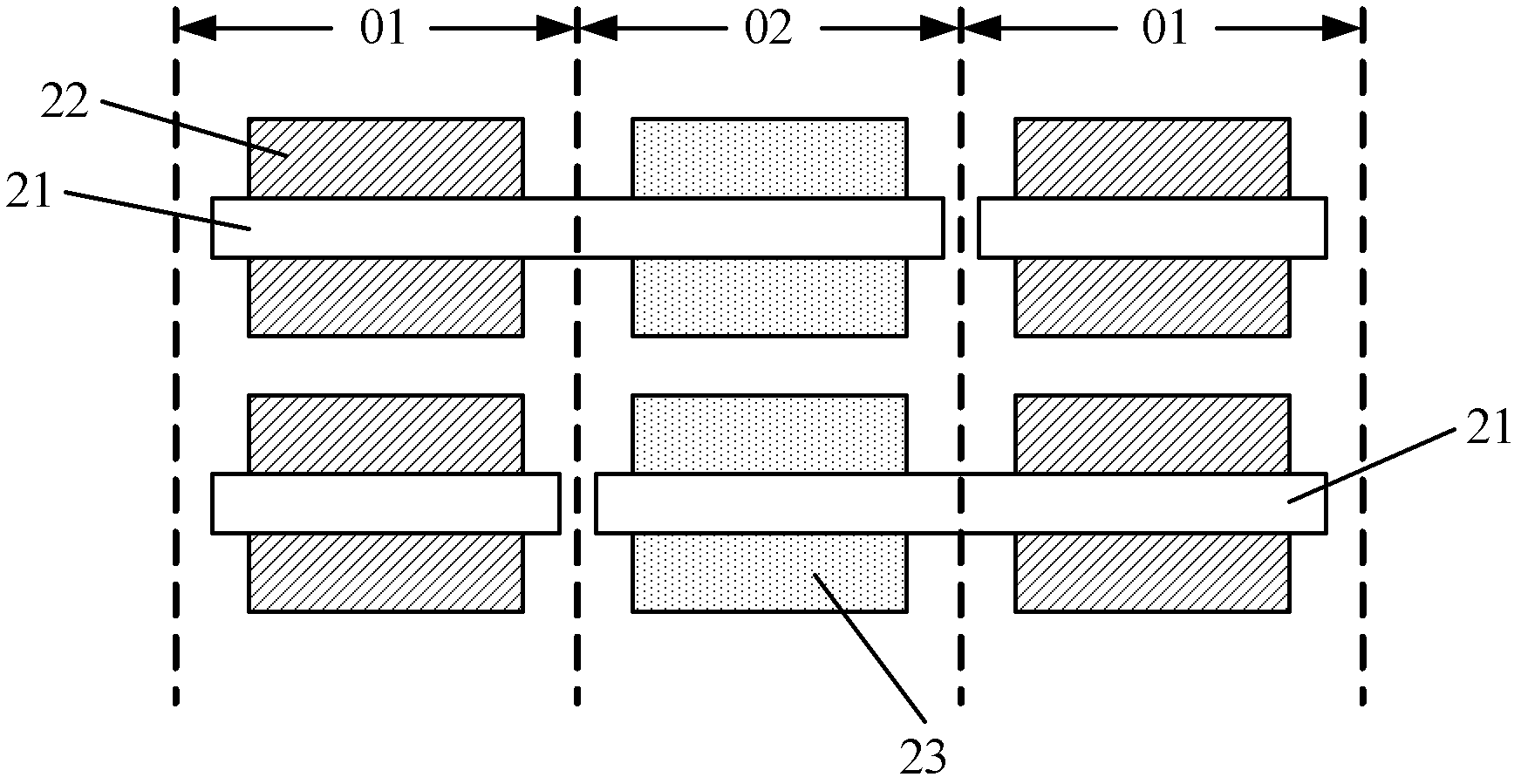

[0041] In existing SRAM memory cells, the gate of an NMOS transistor is usually electrically connected to the gate of a PMOS. In order to improve device integration and avoid the formation of conductive plugs on the surface of the gate structure, in layout design, an NMOS transistor and a PMOS transistor usually share the same gate structure. For details, please refer to figure 2, which is a structural schematic diagram of the common gate of the NMOS transistor and the PMOS transistor in the SRAM memory unit of the prior art, including: an NMOS transistor region 01 and a PMOS transistor region 02 are provided on the semiconductor substrate; the common gate 21 spans the NMOS Transistor region 01 and the boundary of PMOS transistor region 02, a part of the common gate 21 is located in the NMOS transistor region 01, and another part of the common gate 21 is located in the PMOS transistor region 02; in the NMOS transistor region 01, all N-type source / drain regions 22 are formed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com