Heat-bridge-insulation bay window

A bay window and broken bridge technology, which is applied to window sills/thresholds, building components, thermal insulation, etc., can solve the problem of not being able to realize the flat molding production process and factory mass production assembly, not being able to block the transfer of external heat, and affecting the effect of energy saving and thermal insulation and other problems, to achieve the effect of high flat transportation efficiency, good energy saving and heat preservation effect, and safe and reliable broken bridge connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

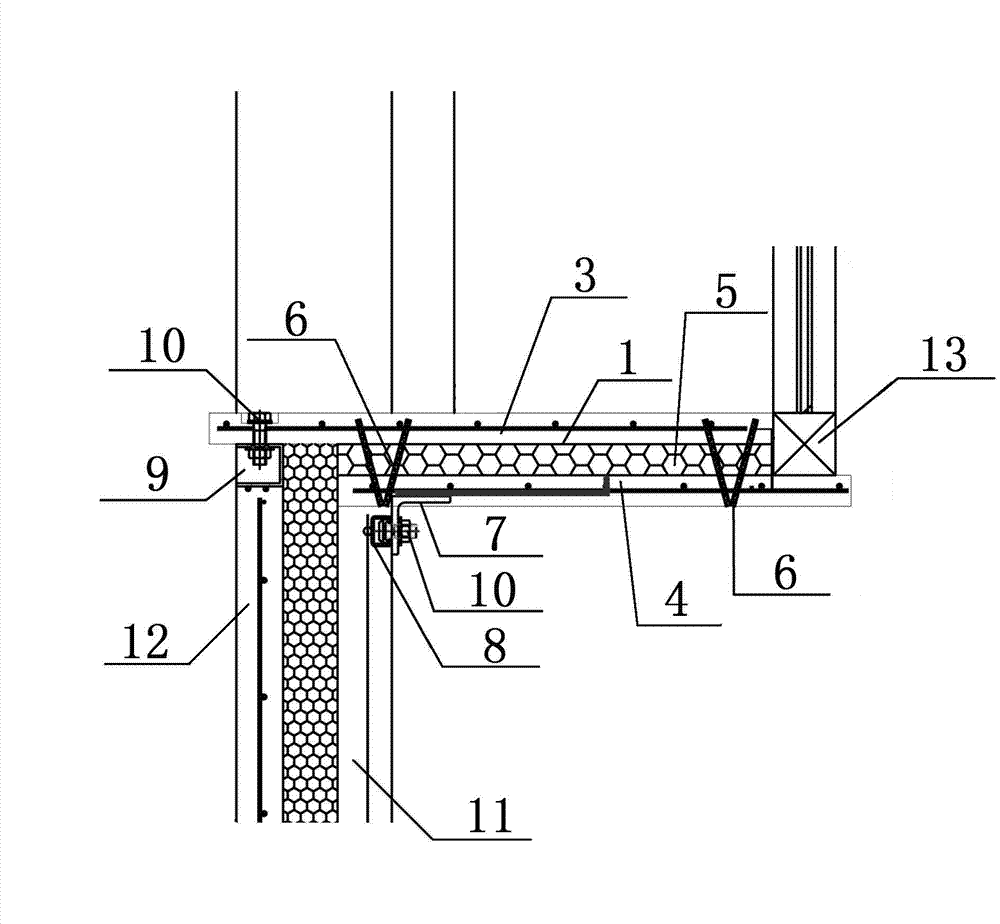

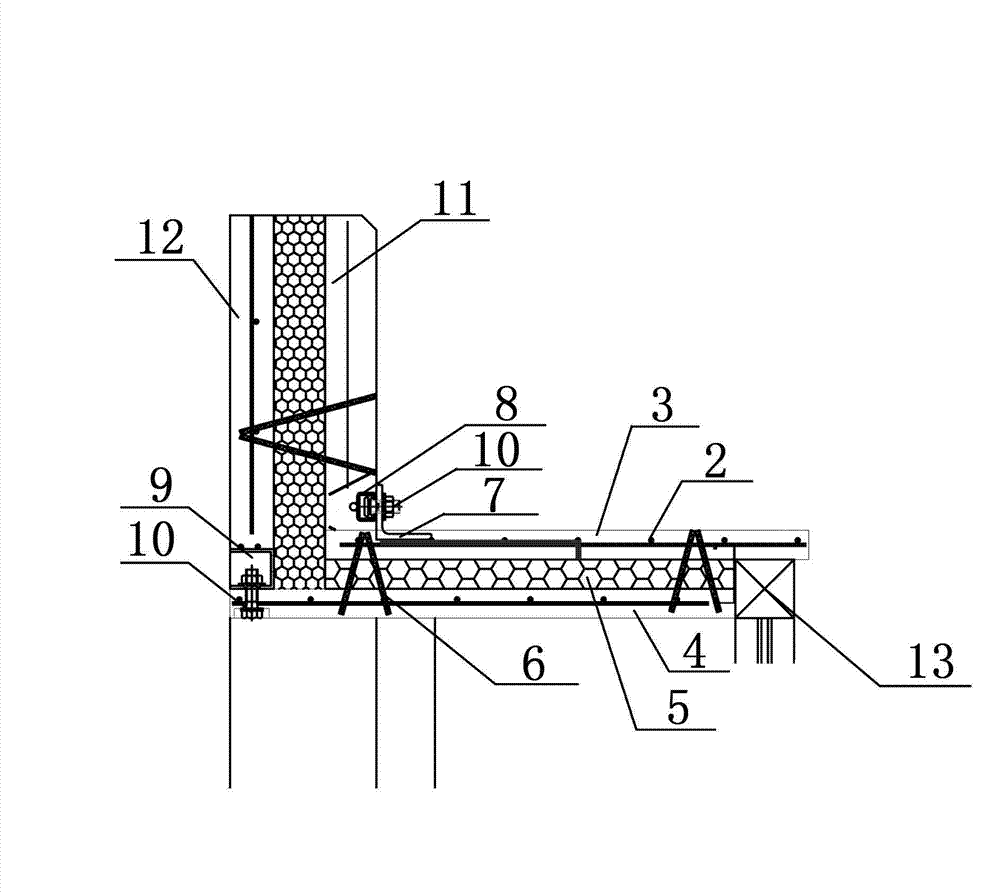

[0013] see figure 1 , figure 2 The bay window of the present invention has an upper deck 2 of the bay window and a lower deck 1 of the bay window. The core panel, the inner and outer panels of the sandwich panel are connected and fixed by non-metallic composite fiber tendons 6 obliquely in both directions. 11 and the sandwich insulation inner wall panel 12 are respectively pre-embedded connection groove 8 and pre-embedded iron box 9, and the upper and lower decks of the outer bay window are connected to the embedded connection groove 8 and the embedded connection groove 8 and The pre-embedded iron box 9 is connected and fixed, and the non-metallic composite fiber reinforcement is basalt fiber reinforcement or glass fiber composite fiber reinforcement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com