Porous silica microsphere preparation method

A technology of porous silica and microspheres, which is applied in the chemical field, can solve the problems of inability to flexibly control the size of silica microspheres and pores, and high requirements for spray technology, and achieves low equipment cost, simple preparation method, and wide application. Effects in the field of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

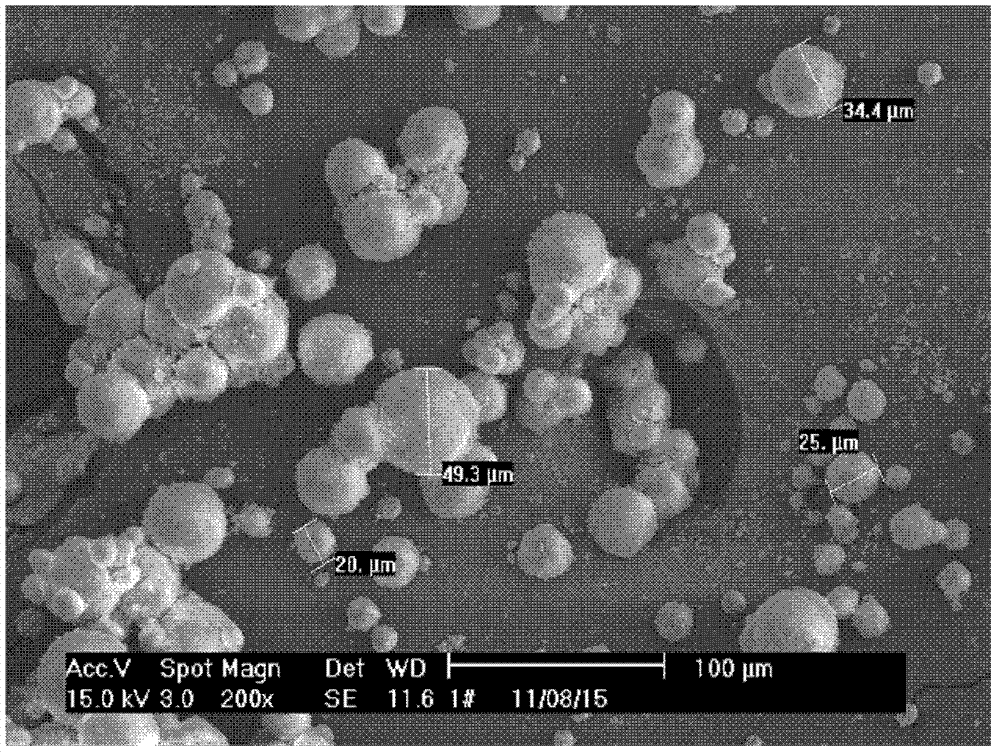

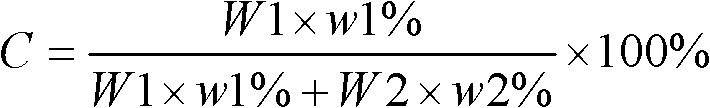

[0022] 500 grams of fully vulcanized silicone rubber emulsion (Beijing Research Institute of Chemical Industry, solid content 28%) and 200 grams of fully vulcanized styrene-butadiene rubber emulsion (Beijing Research Institute of Chemical Industry, solid content 45%) are blended by mechanical stirring to obtain a stable blend Lotion. Then, 100 grams of fully vulcanized silicone rubber and fully vulcanized styrene butadiene rubber composite microspheres were prepared by spray drying method, spray dryer (made by Beijing Research Institute of Chemical Industry), inlet temperature of 150°C, outlet temperature of 60°C.

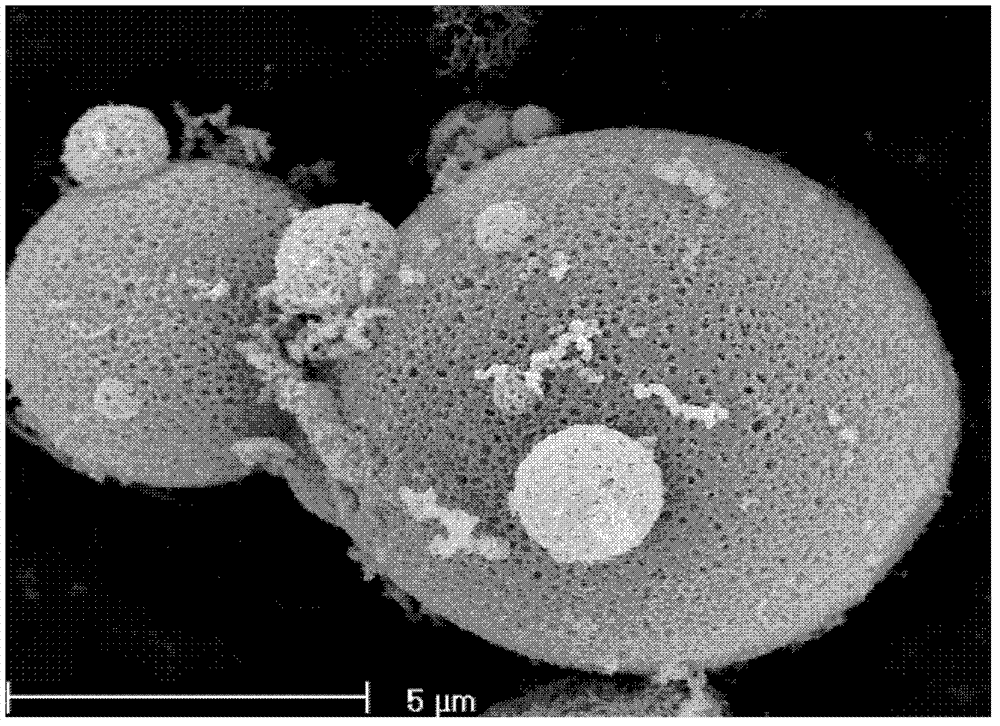

[0023] Weigh 20 grams of the above-prepared composite microspheres in a crucible, put them in a muffle furnace, and ablate at 400°C for 300 minutes under air conditions. 3.1 g of porous silica microspheres were obtained. The average pore diameter is 140 nanometers.

[0024] Compared figure 1 with figure 2 ,visible: figure 1 No holes can be seen on the surface of the...

Embodiment 2

[0026] Put 20 grams of ultrafine fully vulcanized silicone rubber and fully vulcanized styrene-butadiene rubber micron-sized composite microspheres (same as Example 1) in a crucible and placed in a muffle furnace. Under air conditions, at 500 ℃, ablation 180 minute. 3.2 g of porous silica microspheres were obtained. The average pore diameter is 124 nanometers.

Embodiment 3

[0028] Put 20 grams of ultrafine fully vulcanized silicone rubber and fully vulcanized styrene-butadiene rubber micron composite microspheres (same as Example 1) in a crucible, put in a muffle furnace, and ablate 40% under air conditions at 800°C minute. 3.0 g of porous silica microspheres were obtained. The average pore diameter is 104 nanometers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com