Preparation method and application method of CuZr(PO4)2*4H2O material

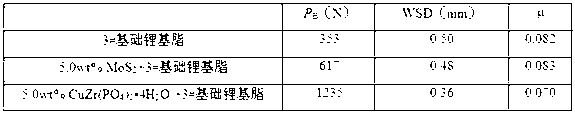

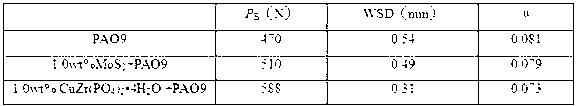

A technology of copper zirconium phosphate and its application method, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of long exchange time, difficult exchange, cumbersome exchange steps, etc., and achieve good load-bearing and anti-wear and anti-friction capabilities , simple synthesis process and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

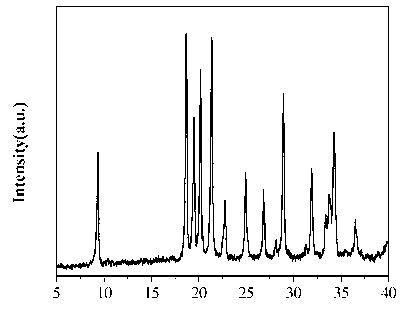

Image

Examples

Embodiment approach 1

[0012] Take 3.5 mL of zirconium nitrate solution with a concentration of 1.0 mol / L and 4.4 mL of a copper acetate solution with a concentration of 1.0 mol / L, mix and stir evenly, add 0.8 mL of phosphoric acid solution with a mass percentage of 85%, and adjust the pH value to 2 , and after 15 minutes of stirring evenly, the obtained blue gel was sealed into a polytetrafluoroethylene-lined reactor, and the reactor was placed in an oven at 180°C. After crystallization for 100 hours, the reactor was taken out, and the conventional The centrifugation method is used for separation, and the obtained solid product is washed with distilled water to neutrality, and the copper zirconium phosphate product is obtained after air-drying at room temperature.

Embodiment approach 2

[0014] Take 3.4mL of zirconium oxychloride solution with a concentration of 1.0mol / L and 1.7mL of a copper acetate solution with a concentration of 4.0mol / L, mix and stir evenly, add 1.7mL of phosphoric acid solution with a mass percentage of 85%, and adjust the pH value to 1.2, and after 10 minutes of stirring evenly, seal the obtained blue gel into a polytetrafluoroethylene-lined reactor, put the reactor in an oven at 180°C, and crystallize for 72 hours, then take out the reactor. The conventional centrifugation method is adopted for separation, and the obtained solid product is washed with distilled water until neutral, and air-dried at room temperature to obtain a copper zirconium phosphate product.

Embodiment approach 3

[0016] Take 1.0 mL of zirconium nitrate solution with a concentration of 4.0 mol / L and 12.0 mL of a copper chloride solution with a concentration of 1.0 mol / L, mix and stir evenly, add 1.1 mL of phosphoric acid solution with a mass percentage of 85%, and adjust the pH value to 1.8, after 10 minutes of stirring evenly, seal the obtained blue gel into a polytetrafluoroethylene-lined reactor, put the reactor in an oven at 220°C, and crystallize for 24 hours, take out the reactor, and use The conventional centrifugal separation method is used for separation, and the obtained solid product is washed with distilled water until it is neutral, and then air-dried at room temperature to obtain a copper-zirconium phosphate product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com