Fabric morphological polymer battery and preparation method thereof

A technology of polymer and polymer film, which is applied in secondary battery manufacturing, final product manufacturing, sustainable manufacturing/processing, etc. It can solve problems such as poor cycle stability, large theoretical specific capacitance, and low biological toxicity, and achieve adhesion Strong, improve work efficiency, good flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] c Preparation of conductive cloth

[0037] Soak the fabric treated in step a in 100mL monomer solution for 1 hour, and stir it on a magnetic stirrer, then slowly add the oxidation initiating solution dropwise therein, and continue to stir for 2 hours to 4 hours after dropping.

[0038] d wash and dry

[0039] Wash the fabric treated in step c with absolute ethanol and distilled water until the solution has no foam and black solid particles fall off, and then dry at 50° C. for 1 hour.

[0040] e Electrolyte layer preparation

[0041] Soak the non-woven fabric in a 1mol / L-2mol / L electrolyte solution for 1 hour, take it out and let it dry until there is no free water dripping, use one of sodium chloride solution, potassium chloride solution or hydrochloric acid.

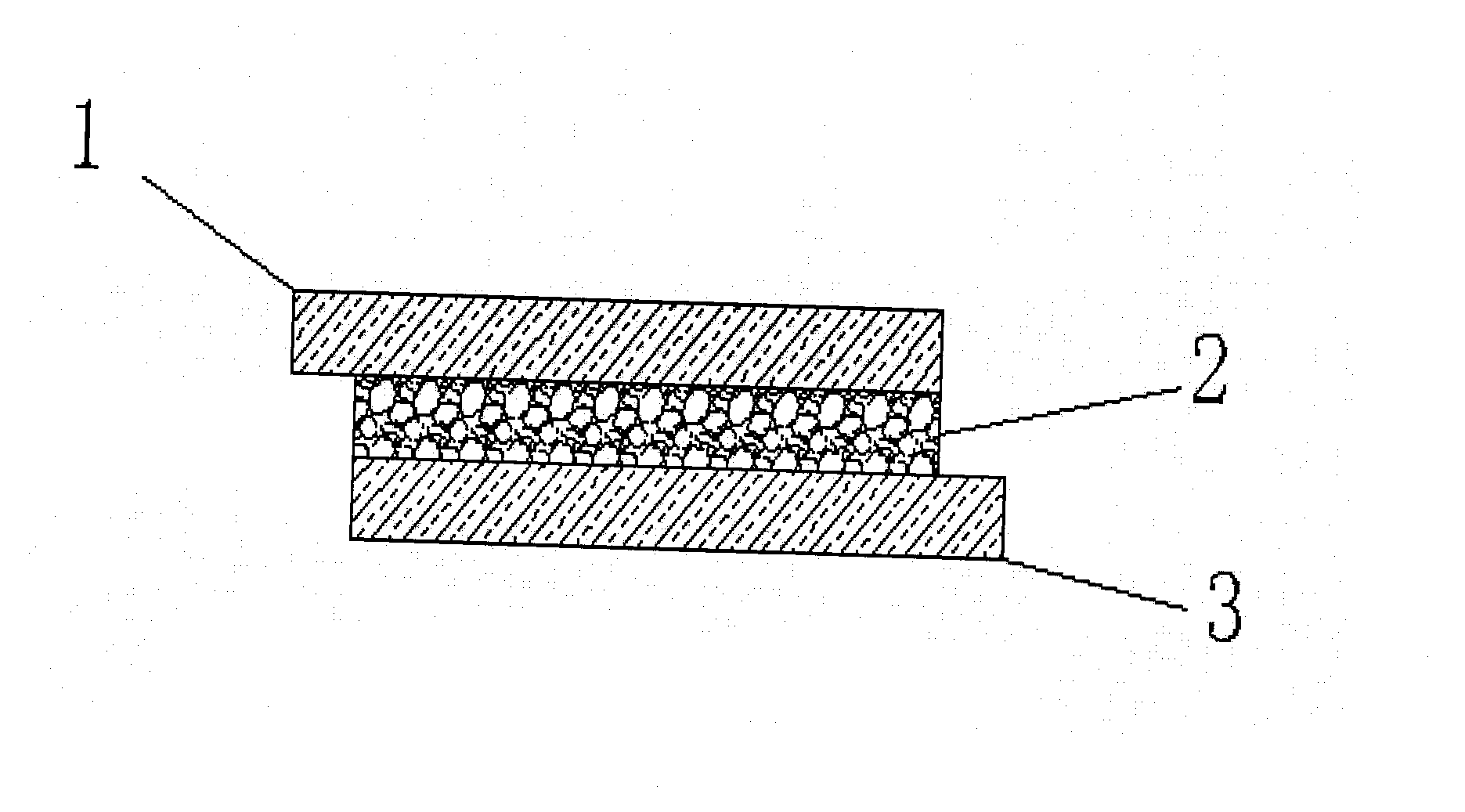

[0042] fBattery assembly

[0043] The conductive fabric electrode material prepared in step d and the electrolyte layer prepared in step e are assembled into a battery, and encapsulated with a polymer film.

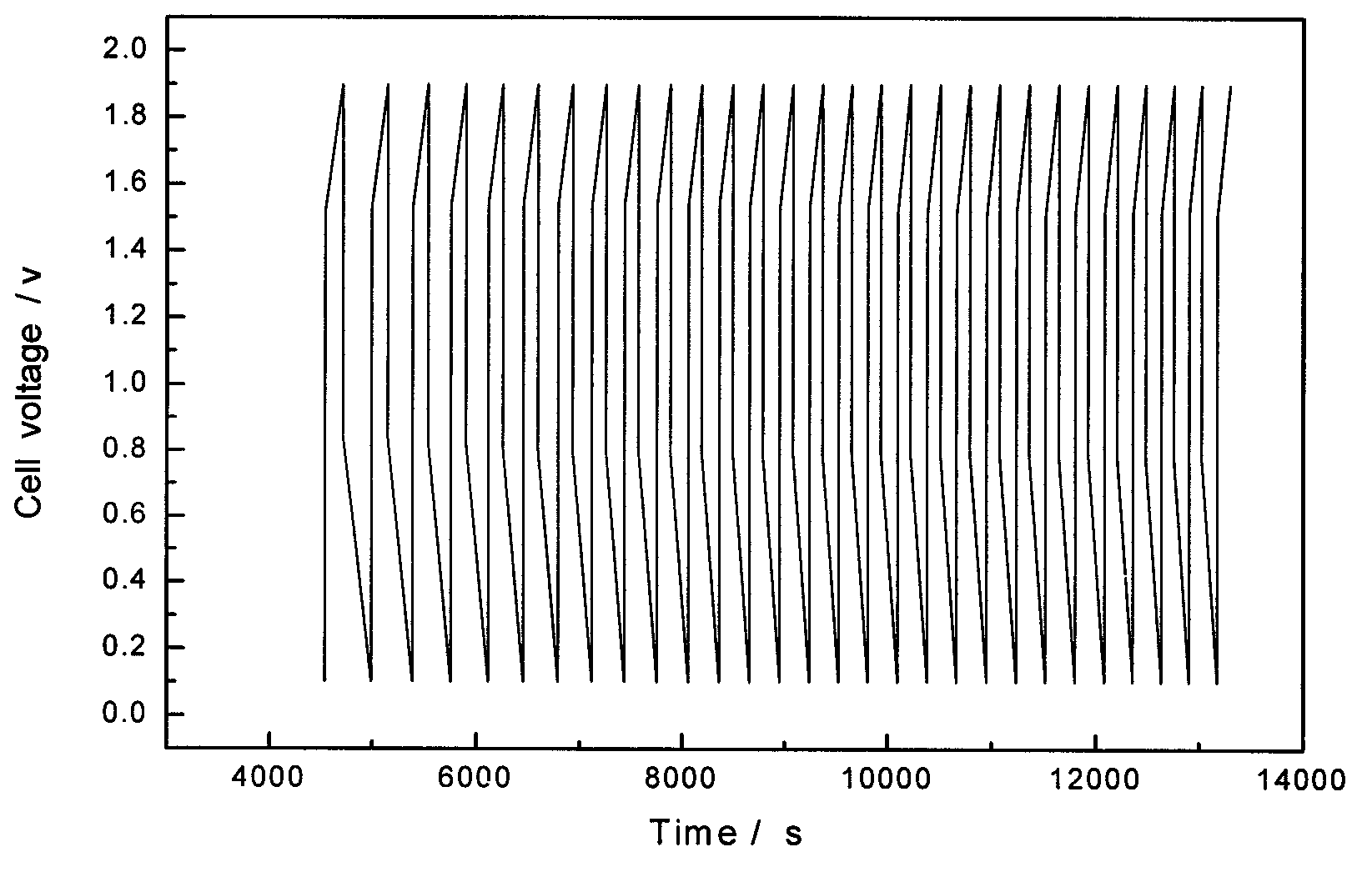

Embodiment 1

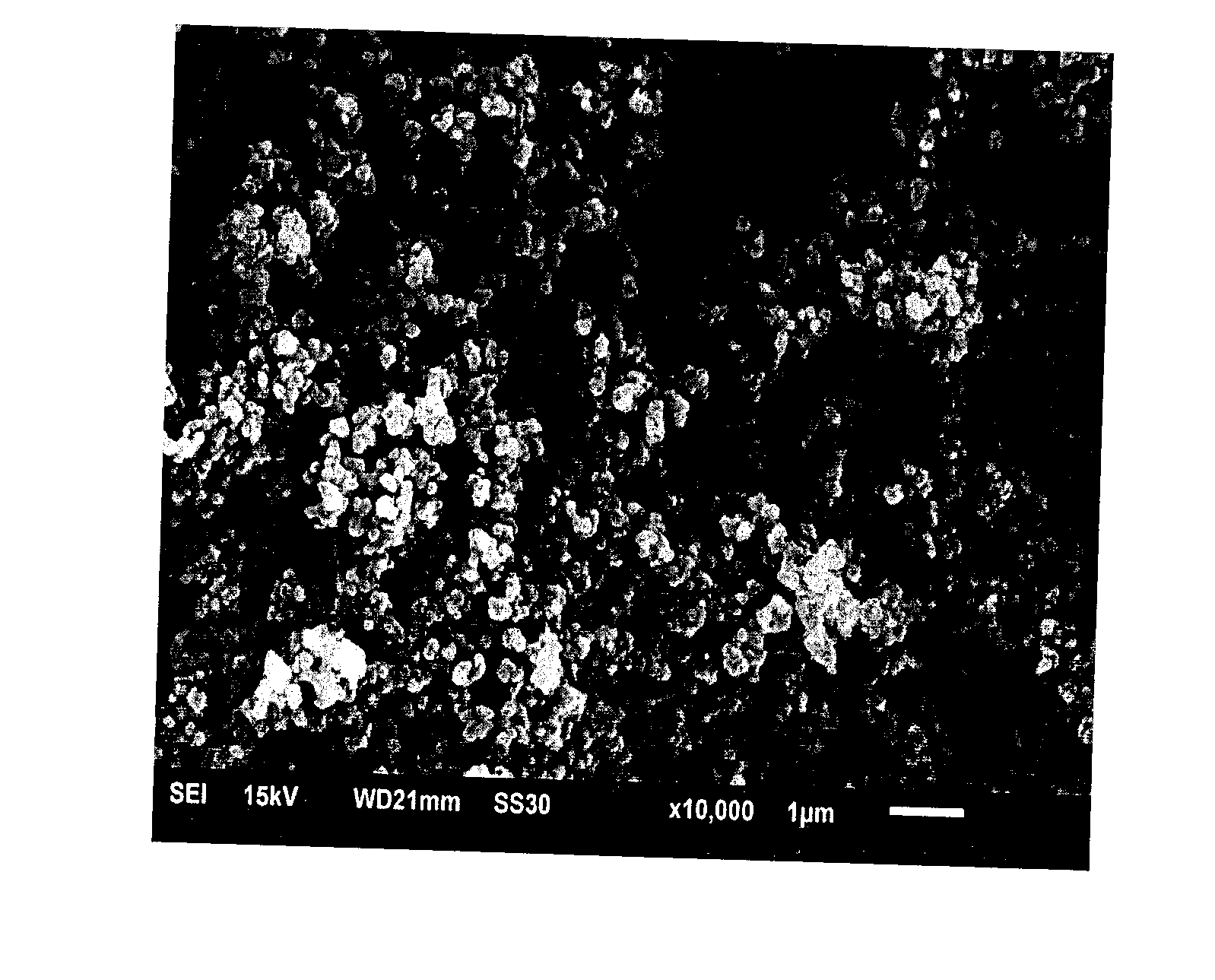

[0045]According to the above-mentioned preparation method, the cotton fabric 6cm * 6cm size of daily use is trimmed. Boil at 50°C for 1 hour with a treatment solution with a mass ratio of sodium carbonate to detergent of 3:5, wash with distilled water, and dry in an oven at 50°C. At room temperature, ferric chloride and deionized water were made into 100mL of 0.5mol / L oxidation initiating solution, and the pyrrole monomer obtained by distillation was mixed with dopant sodium dodecylbenzenesulfonate, surfactant ten Hexaalkyltrimethylammonium bromide and deionized water were prepared into 100 mL monomer mixed solution, wherein the concentration of pyrrole monomer was 1.0 mol / L, the concentration of dopant was 0.5 mol / L, and the concentration of surfactant was 0.0001 mol / L; Soak the treated cotton cloth in the monomer mixed solution and stir it on a magnetic stirrer. At the same time, slowly add the oxidation initiation solution into the beaker. Finally, continue to stir on the ...

Embodiment 2

[0047] According to the above-mentioned preparation method, according to the above-mentioned preparation method, the hemp fabric 6cm * 6cm size of daily use is trimmed. Then boil it at 70°C for 1 hour with a treatment solution with a mass ratio of sodium carbonate and detergent of 3:6, wash it with distilled water, and dry it in an oven at 50°C. At room temperature, ammonium persulfate and deionized water were made into 100mL of 1.0mol / L oxidation initiating solution, and the distilled aniline monomer, dopant toluenesulfonic acid, and surfactant dodecyldimethyl Benzyl ammonium chloride and deionized water were prepared into 100 mL monomer mixed solution, wherein the concentration of aniline monomer was 1.0 mol / L, the concentration of dopant was 1.0 mol / L, and the concentration of surfactant was 0.001 mol / L; Soak the treated polyester fabric in the monomer mixed solution and stir it on a magnetic stirrer. At the same time, slowly add the oxidation initiating solution to the bea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com