Drug-loaded saccule and manufacture method thereof

A manufacturing method and technology of balloons, which are applied in the field of medical devices, can solve problems such as the inability of direct and firm adhesion of drugs, and achieve the effects of preventing mutual aggregation, reducing surface tension, and accelerating release and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

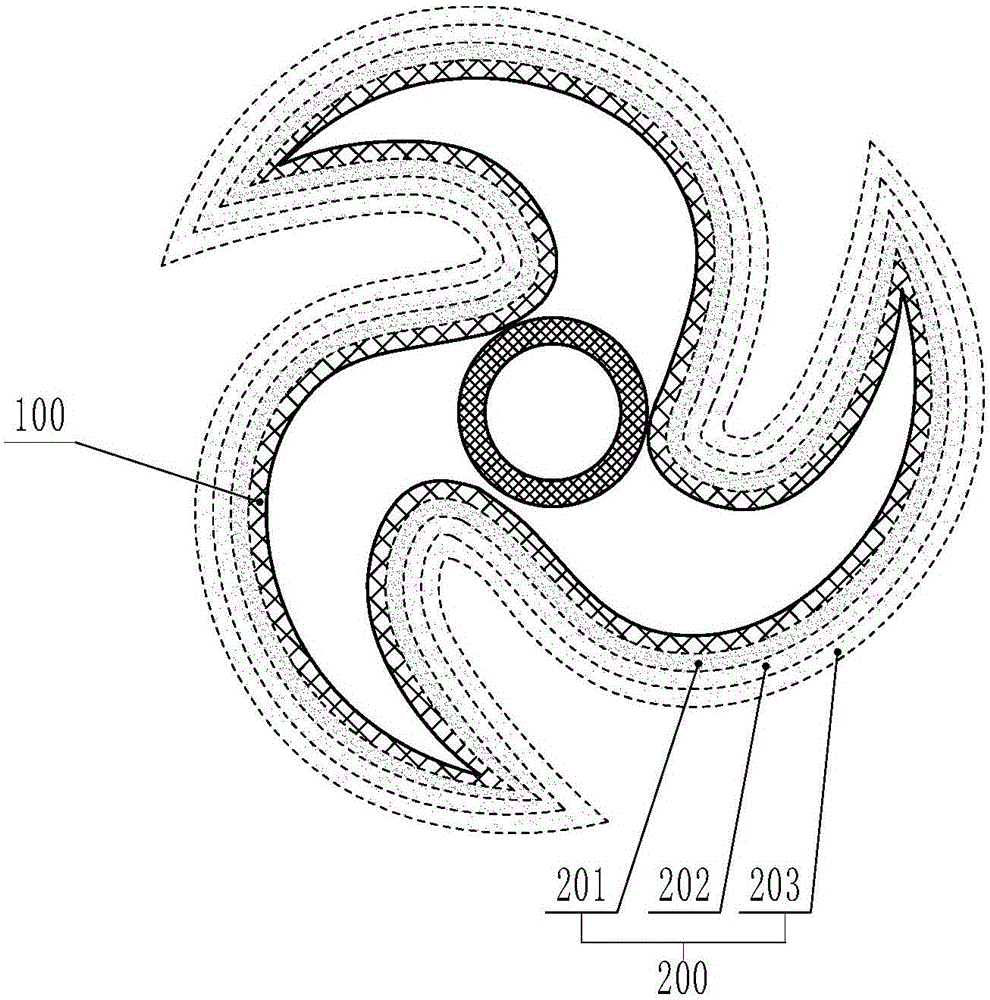

[0057] A. Balloon treatment: Take a 6.0×80mm (produced by Bard Company) balloon catheter, perform wrinkling treatment on the surface of the nylon balloon, and fold it into 5 petals with a flap folding machine (model VBT produced by BLOCKWISE Company).

[0058] B. Composite coating drug solution: prepare solutions with 5 concentration gradient levels: dissolve a certain amount of paclitaxel and PEG2000 in different ratios of ethanol / water (volume ratio), and prepare 5 parts of coating drug solutions in sequence. The total concentration of the coating drug solution is 50%;

[0059] a: Paclitaxel 9.99mg, PEG2000 0.1mg, solvent 20ml (the volume ratio of ethanol / water is 99:1), take 4ml;

[0060] b: Paclitaxel 7.9mg, PEG2000 2.1mg, solvent 20ml (the volume ratio of ethanol / water is 80:20), take 2ml;

[0061] c: Paclitaxel 5.9mg, PEG2000 4.1mg, solvent 20ml (the volume ratio of ethanol / water is 55:45), take 2ml;

[0062] d: Paclitaxel 3.9mg, PEG2000 6.1mg, solvent 20ml (the volume...

Embodiment 2

[0070] A drug-loaded balloon for treating vascular stenosis is prepared by using a nylon balloon.

[0071] A. Balloon treatment: wrinkle the surface of the balloon; take a 6.0×80mm (produced by Bard) balloon catheter, wrinkle the surface of the nylon balloon, and use a flapper (the model produced by BLOCKWISE is VBT), Fold into 3 pieces.

[0072] B. Composite coating drug solution: configure 7 concentration gradient grade solutions: dissolve a certain amount of rapamycin and N-methyl-D-glucose methylamine in different ratios of methanol / water (volume ratio) , and configure 7 solutions in turn. The total concentration of the coating drug solution is 10%;

[0073] a: Rapamycin 9.5mg, N-methyl-D-glucose methylamine 0.5mg, solvent 100ml (the volume ratio of methanol / water is 90:10), take 10ml;

[0074] b: rapamycin 9mg, N-methyl-D-glucose methylamine 1mg, solvent 100ml (the volume ratio of methanol / water is 70:30), take 10ml;

[0075] c: 8mg of rapamycin, 2mg of N-methyl-D-glu...

Embodiment 3

[0086] A drug balloon for treating blood vessel stenosis is prepared by using a nylon balloon.

[0087] A. Balloon treatment: take a 7.0×80mm (produced by Bard Company) balloon catheter, perform wrinkle treatment on the surface of the nylon balloon, and fold it into 4 petals with a flap folding machine (model VBT produced by BLOCKWISE Company).

[0088] B. Composite coating drug solution: configure 2 solutions of concentration gradient levels: dissolve a certain amount of paclitaxel, Tween 80, and acetamide in DMF / water (volume ratio) of different proportions, and configure 2 parts in sequence Apply drug solution. The total concentration of the coating drug solution is 80%;

[0089] a: Paclitaxel 8mg, Tween 80 1.5mg, acetamide 0.5mg, solvent 12.5ml (the volume ratio of DMF / water is 85:15), take 6ml;

[0090] b: Paclitaxel 2mg, Tween 80 5.5mg, acetamide 2.5mg, solvent 12.5ml (the volume ratio of DMF / water is 40:60), take 6ml;

[0091] Label the above two solutions as a and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com